Ultrasonic Water Level Sensor: Precision in Liquid Measurement

In the realm of liquid level measurement, Ultrasonic water level sensor have emerged as a reliable and innovative solution. These sensors use ultrasonic waves to measure the level of water or other liquids. They provide a non-invasive and precise alternative to traditional methods.

Working Principle

At the core of an ultrasonic water level sensor is the idea of ultrasonic wave movement. The sensor has a transducer that sends out ultrasonic waves. These are high-frequency sound waves that people cannot hear, usually above 20 kHz.

These waves move through the air at a known speed. The ambient temperature mainly affects that speed. When the ultrasonic waves hit the surface of the liquid, they bounce back to the sensor.

The sensor’s transducer also acts as a receiver. It detects the reflected waves. The sensor measures the time it takes to send ultrasonic waves and get their echoes back. This helps it find the distance to the surface of the water.

Researchers often know how far the sensor is from the top of the container. You can also use this as a reference value.

To find the water level, subtract the measured distance from this reference value. The sensor is 5 meters above the container. The distance from the sensor to the water surface is 3 meters. This means the water level is 2 meters.

Structure and Components

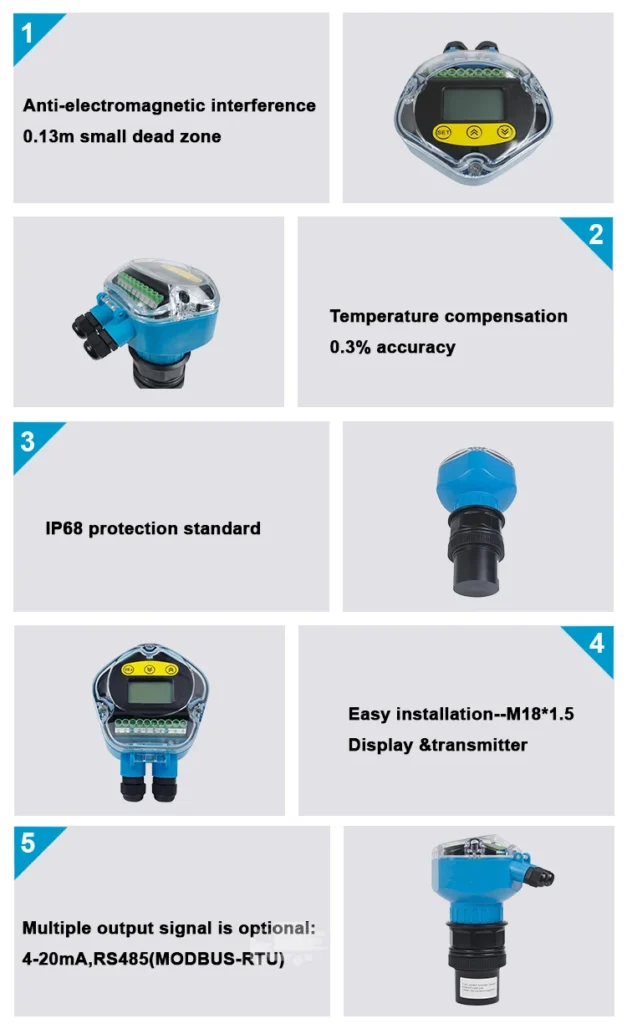

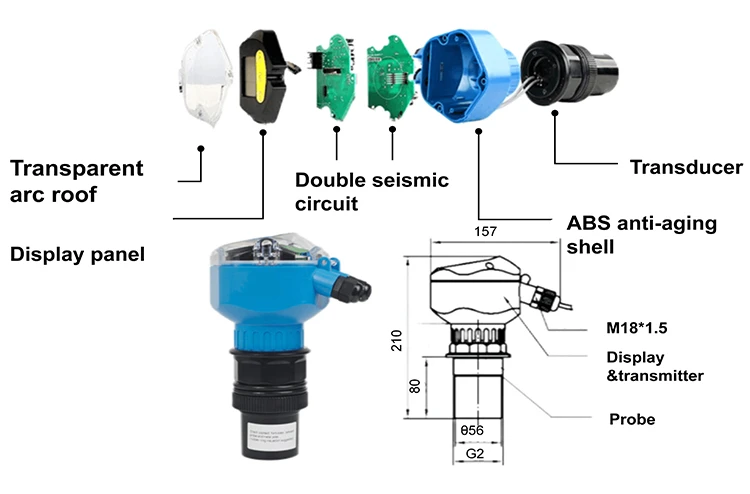

An ultrasonic water level sensor has several important parts. The transducer is the most important part. It sends and receives ultrasonic waves. Engineers often make it from piezoelectric materials.

These materials can turn electrical energy into ultrasonic waves when they send them out. They can also do the opposite when they receive waves.

The sensor has a microcontroller or a signal-processing unit. This part makes electrical signals to activate the transducer for wave emission. It measures the time between sending and receiving waves. Then, it calculates the time data to give a useful water level reading.

Also, there are usually connections for power and data output. The power connection links the sensor to a power source.

The data output connection can send information in various ways. It can use analog signals like 4 – 20 mA. It can also use digital signals such as RS – 485 or Modbus.

Wireless communication methods like Bluetooth and Wi-Fi are good choices. They send the measured water level data to a display unit, data logger, or control system.

Advantages

One big advantage of ultrasonic water level sensors is that they do not touch the liquid. Users can measure liquids without contact. This lets them use sensors on many different types of liquids.

These include corrosive, thick, or dirty liquids. Such substances can harm or contaminate regular sensors. This non-contact feature also lowers the risk of sensor fouling. It ensures reliable operation over time with little maintenance.

Ultrasonic sensors provide accurate water level measurements. They can sense small changes in water levels. This makes them good for tasks that need close watching.

Moreover, they have a fast response time, allowing for real – time monitoring of water levels. This quick response is important in flood control systems. Detecting rising water levels quickly can trigger alerts and help take preventive actions.

These sensors are also relatively easy to install. You can place them on top of a tank, reservoir, or other water-holding structures. This does not need complicated plumbing or hard installation.

Their installation options are flexible. Some models have wireless communication. This makes them good for new setups and for updating old systems.

Applications

Ultrasonic water level sensors are used in many industries and applications. In water and wastewater management, workers check the levels in storage tanks, reservoirs, and treatment plants. This helps manage water resources well. It makes sure there is enough supply and stops overflows.

Ultrasonic water level sensors are key tools for monitoring the environment. They check how high the water is in rivers, lakes, and wetlands. This data helps us predict floods, check water quality, and study the environment.

You can also use them in systems that collect rainwater. They check how much water is in the storage tanks. This makes the best use of this sustainable water source.

Installation and Usage Considerations

When you install an ultrasonic water level sensor, you should think about a few important factors. First, ensure that the sensor has a clear line – of – sight to the liquid surface.

Any obstacles, like pipes, structures, or floating objects, can disrupt the accurate measurement of ultrasonic waves. You should carefully set the sensor’s installation height. Base this on the highest and lowest expected water levels.

Ambient temperature greatly affects the speed of sound. This, in turn, impacts the accuracy of the measurement. Many ultrasonic sensors have built-in temperature compensation. This feature changes the measurement based on the temperature around it.

For precise applications, you can use extra temperature sensors to enhance the compensation.

Most ultrasonic water level sensors need calibration before use. This means measuring the distance to a known object that is at a fixed spot. Next, change the sensor’s settings to match the value you measured. Regular calibration, as the manufacturer suggests, helps keep the sensor accurate over time.

Maintenance

Caring for ultrasonic water level sensors is quite simple. Clean the transducer’s surface often. This helps get rid of dust, dirt, and other things that can affect ultrasonic waves.

Look for any signs of damage or loose cables in the connections. For sensors that can communicate wirelessly, check that the communication module is working well. Also, charge or replace the battery when needed.

Check the sensor’s performance often. Compare its readings with other trusted measurement methods or past data. If someone finds any big differences, they may show a problem with the sensor. Then, you should take steps to fix it.

Conclusion

Ultrasonic water level sensors have changed how we measure liquid levels. They provide accuracy, reliability, and versatility. Their non-contact operation, high precision, and wide range of uses make them essential tools in many industries.

By learning how these sensors work, how to install them, and how to maintain them, users can get the most benefits. This will help make sure we monitor water levels accurately and efficiently. As technology keeps advancing, we can expect better performance from ultrasonic water level sensors. This will open up new ways to measure liquid levels.