How Do water level probe sensor Work?

Water level detector sensors check how high the water is. They change these level measurements into electrical signals. Many industries use them, such as water management, environmental protection, and industrial automation. Here is an overview of the different types of water level sensors and how they work.

Types of Water Level Sensors and Their Principles

1. Float-Type Water Level Sensor

– Principle: This sensor has a float switches that moves up and down with the water levels. It detects changes in the water. Many people think of the float as a mechanical arm linked to a switch or encoder.

When the water flows levels change, the float moves up and down. This movement turns on the switch or changes the encoder’s position. It then sends signals.

– Uses: Great for managing home water systems and checking tank levels.

2. Pressure Water Level Sensor

– Principle: It works on the hydrostatic principle. The pressure at a point underwater depends on the height of the water above it. People often put these sensors at the bottom of a body of water or a container. They measure pressure to find out the water level data.

– Uses: Great for deep wells, marine monitoring, and industrial water treatment systems.

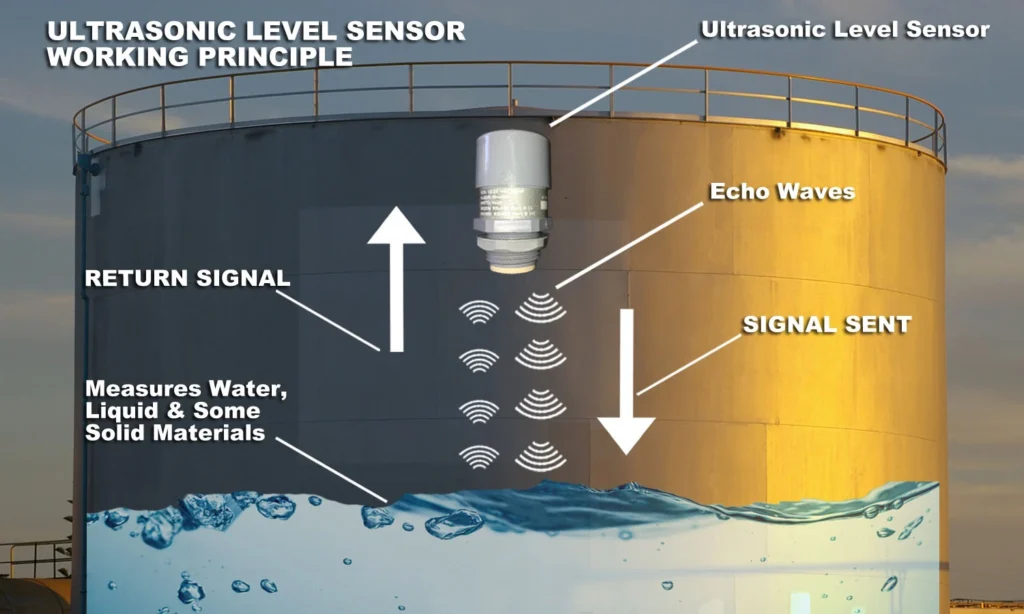

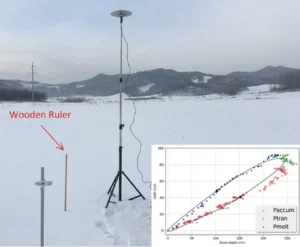

3. Ultrasonic Water Level Sensor

– Principle: This sensor uses sound waves that we cannot hear. The water level detector sends out pulses that bounce back from the water surface. It measures the time it takes to send and receive these pulses. This helps find the distance and the water levels.

– Advantages:

– Non-contact measurement avoids corrosion, contamination, or sensor damage.

– High accuracy and stability are usually achieved. The typical accuracy is ±0.2mm in ideal conditions.

– It can work in the dark or in low light. It can also handle dust and humidity.

– “Versatile for liquids that are high-temperature, toxic, or volatile, and for different level changes.”

– “Needs less maintenance because there are no parts that touch directly.”

–”Simple installation on top of vessels makes it easier.”

– Uses: Great for rivers, lakes, reservoirs, and storage containers in industries.

4. Radar Water Level Sensor

Principle: Radar sensors work like ultrasonic level sensors for water. They use electromagnetic waves, not sound. These sensors send microwave signals to the surface of the water.

They receive signals that bounce back to measure water levels. They do this by looking at time differences.

– Advantages:

– High precision is ideal for places that need very accurate measurements.

– Non-contact measurement helps keep you safe from liquids.

– Can handle tough weather and dirty environments.

– Applications: Great for rivers, lakes, reservoirs, and storage tanks used in industries.

5. Capacitive water level probe

– Principle: It works by changing capacitance. As the water level changes, the space between two conductive plates changes too. This space can be air or water.

This change affects the electrical capacity. By measuring this change, we can find out the water levels.

– Advantages:

– Easy installation and maintenance with a simple structure.

– Compatible with different liquids that have various dielectric constants.

– Applications: Ideal for use in storage water tanks, oil reservoirs, and water purification systems.

6. Photoelectric water level probe

– Operating Principle: It uses a light emitter and a detector to sense water levels. When the water level is too high water levels, something blocks or bends the light. This means the receiver may not see the light or only gets a weak signal to measure the level.

– Advantages:

– Non-contact Measurement: This method stops the sensor from touching the liquid directly.

– Quick Response Time: Great for situations that need fast reactions.

– Application Scenarios: Great for managing water at home and checking liquid levels in industries.

7. Resistive water level probe

The system measures levels by checking how well water conducts electricity. When water levels go up, the resistance between the electrodes goes down. When levels drop, resistance goes up. This change in resistance helps us find the water level.

– Advantages:

– Low Cost: Perfect for low-budget settings.

– Simple Design: It is easy to install and maintain.

– Use Cases: Great for controlling water in homes and checking levels in factories.

8. Magnetic level sensor for water

– Working Principle: It uses a magnetic float that moves with the water levels. This float works with an external magnetic level switch or magnetostrictive material. This interaction causes a change in the electrical signal.

– Advantages:

– High Reliability: Good for stable and long-term use.

– Non-contact Measurement: This method avoids touching the liquid directly.

– Application Scenarios: Ideal for storage tanks, oil tanks, and water treatment systems.

9. Impedance water level probe

– Working Principle: It measures changes in resistance when the probe touches the liquid. Changes in conductivity change the resistance. This shows the water level.

– Advantages:

– Low Cost: Suitable for budget-conscious needs.

– Simple Design: Makes installation and maintenance easy.

– Application Scenarios: Good for managing water at home and monitoring water levels in industries.

10. Inductive and Magnetostrictive Level Meter

– Working Principle: It detects water levels with electromagnetic induction. It also senses changes in the position of magnetic materials in a magnetic field. This device is made for specific industrial uses.

– Advantages:

– High Accuracy: Great for when you need precise measurements.

– Non-contact Measurement: This method does not touch the liquid directly.

– Application Scenarios: Suited for industrial storage tanks and oil tanks.

11. Servo Water Level Sensor

– Working Principle: It uses a motor-driven probe or buoy to measure indirectly. It also gives real time data position feedback.

– Advantages:

– High Precision: Good for situations that need very accurate measurements.

– Adaptable: Can be used with a wide variety of liquids and environmental conditions.

– Use Cases: Ideal for industrial storage and oil tanks.

Industry Applications for Water Level Sensors

Water level detector sensors are helpful tools used in many industries, such as:

1. Industrial Automation:

– Used to check tank levels and control reactors. This helps engineers make processes better and automate them.

2. Environmental Monitoring:

– Used in rivers, lakes, and reservoirs to track water levels.

– It provides flood warnings and helps manage water levels.

3. Water Treatment:

– Ensure effective water treatment by monitoring levels in sewage tanks, sedimentation tanks, and pools.

4. Agriculture:

– Help farmers use water better. Check irrigation systems to improve how crops use water.

5. Healthcare:

– Make sure patients are safe and comfortable by checking tank levels in equipment like ventilators.

6. Construction:

– Keep an eye on storage tank levels to manage water supply and drainage well.

Choosing the Right Water Level Sensor

Choosing the right water level sensor means thinking about:

1. Measuring Wide Range: Pick a sensor that fits the expected changes in water level for your use.

2. Choose a sensor that provides the accuracy you need for your measurements.

3. Environmental Conditions: Make sure the sensor works well in different temperatures, humidity levels, and against corrosion.

4. Choose sensors that are simple to install and easy to maintain.

5. Cost-Effectiveness: Find a balance between budget limits and how well the sensors work.

By looking at these factors, you can pick a sensor that meets your needs. This will help you check water levels accurately and easily.w

Summary:

A water level sensor can work in many places and meet various needs. They use contact sensors, like float and impedance sensors. They also use sensors that do not touch, like ultrasonic and radar sensors. These sensors can sense changes in physical properties, such as pressure and capacitance.

They are important for automation, remote level monitoring, and safety alerts. They provide accuracy and safety for both home and industrial use. Choosing the right sensor means looking at factors like measurement accuracy, durability, ease of installation, and cost.