Ultrasonic Wind Speed and Direction Sensor: Measuring the Wind

In meteorology, environmental monitoring, and industry, measuring wind speed and direction accurately is very important. Ultrasonic wind speed and direction sensors are a new solution. They provide accurate measurements, reliability, and advanced features.

How Ultrasonic Wind Speed and Direction Sensors Work

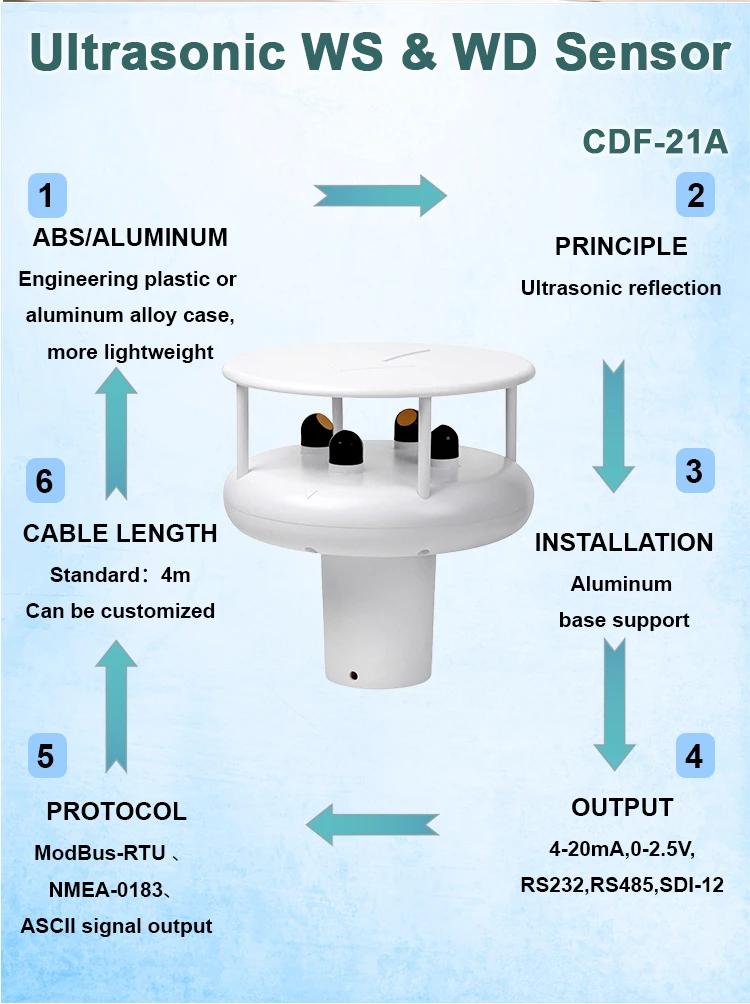

Ultrasonic wind speed and direction sensors work by using ultrasonic waves. Hae sensoria ex multis transductoribus ultrasonicis constant. Plerumque in certa figura geometrica disposita sunt, ut crux vel circulus. The transducers emit and receive ultrasonic waves.

When the wind blows, it changes how ultrasonic waves travel between the transducers. We measure how long it takes for an ultrasonic wave to go from one transducer to another. When there is wind, the wave can speed up or slow down.

This depends on the direction of the wind and the path of the waves. The sensor can find the wind speed and direction. It does this by comparing how long ultrasonic waves take to travel in different directions.

For example, think about a sensor with four transducers set up in a cross shape. When there is no wind, the ultrasonic waves travel between the transducers at the same speed. When the wind blows, waves moving with the wind travel faster.

Waves that move against the wind take more time. The sensor can find the strength and direction of the wind by looking at these time differences.

Key Features

High Precision

Ultrasonic measure wind speed and direction sensors are known for their exceptional precision. They can measure wind speeds with an accuracy of up to ±0.1 m/s and wind directions with an accuracy of a few degrees.

This high level of precision helps people see small changes in the wind. This makes them good for such places. This includes research labs, advanced weather stations, and wind turbine control systems.

No Moving Parts

One major benefit of ultrasonic sensors is that they have no moving parts. Unlike traditional mechanical anemometers, like cup and vane anemometers, ultrasonic sensors have a solid-state design.

This removes the wear and tear from moving parts. It also cuts down on the need for regular maintenance and calibration. As a result, ultrasonic sensors have a longer lifespan and offer more reliable performance over time.

Fast Response Time

Ultrasonic sensors can measure wind speed and direction in real time. They respond very quickly. They can easily see changes in the wind. This makes them good for situations where someone needs to watch quick changes in the wind.

For example, in aviation, sudden gusts can be a serious threat to aircraft safety. The fast response time lets these sensors capture short wind events accurately. This provides useful data for research and analysis.

Robust and Durable

These sensors are made to handle tough weather conditions. Manufacturers often make them from strong materials. These materials resist rust, UV rays, and extreme temperatures.

This makes them good for outdoor use in different climates, from dry deserts to cold polar areas. Their strong design makes sure they work well, even in strong winds, rain, snow, and dust.

Ultrasonic Wind Speed and Direction Sensor Applications

Meteorology

In weather applications, ultrasonic sensors for wind speed and direction are very important for forecasting and monitoring. Weather stations around the world use them to collect wind data.

This data helps us predict weather patterns, track storms, and issue weather warnings. The sensors are very accurate and respond quickly. This helps weather experts get clear and current information about wind conditions. This makes weather forecasts more accurate.

Aviation

The aviation industry depends on accurate wind measurements for safe and efficient flights. Airports and planes use special sensors to detect wind. They give real-time information about wind speed and direction to pilots and air traffic controllers.

This data helps with take-off and landing calculations. It also helps plan flight paths and avoid dangerous wind conditions, such as wind shear.

Ultrasonic sensors react fast and with precision. This helps pilots get timely wind information. With this data, they can make good choices and keep flights safe.

Renewable Energy

Wind turbines provide a lot of renewable energy. To improve their performance, we need precise wind measurements. Ultrasonic wind speed and direction sensors help wind farms track wind conditions. They change how wind turbines work and face them as needed.

These sensors measure wind speed and direction all the time. They help boost the energy produced by wind turbines. They also make things more efficient and lessen wear on the turbine parts.

Ultrasonic sensors are reliable and durable. This makes them a good choice for the tough outdoor conditions of wind farms.

Environmental Monitoring

Ultrasonic wind sensors help monitor the environment. They help us study how pollutants spread. They also show how dust and pollen move.

Finally, they explain how wind affects ecosystems. Scientists check how fast the wind blows and which way it goes. This helps them see how pollutants travel in the air.

It is important to know this to find ways to improve air quality. These sensors can track how sand dunes move. They can watch how wildfires spread and how animals behave when the wind changes.

Comparison with Traditional Sensors

Ultrasonic wind speed and direction sensors have many clear benefits compared to traditional wind measurement sensors. These traditional sensors are cup anemometers and vane anemometers.

Traditional sensors often struggle with accuracy, especially in low wind speeds. They may also need regular calibration. They are also more likely to break down due to their moving parts. This can lead to downtime and higher maintenance costs.

Ultrasonic sensors give very accurate measurements for many wind speeds, even at very low speeds. Their solid-state design removes the need for moving parts.

This reduces the risk of mechanical failure and cuts down on maintenance needs. Ultrasonic sensors respond quickly and work well in tough environments. This makes them a better choice for many uses.

Conclusion

Ultrasonic wind speed and direction sensors have emerged as a game – changing technology in the field of wind measurement. With their precise design, no moving parts, quick response time, and strong build, they have clear benefits over traditional sensors.

Many industries use these sensors. This includes meteorology, aviation, renewable energy, and environmental monitoring. They provide accurate and reliable wind data.

As technology improves, ultrasonic wind sensors will likely become more advanced. This will boost their performance and widen their uses in the future.

This article covers the core aspects of ultrasonic wind sensors. If you want to look at a specific part in more detail, just let me know. This could be about their role in an industry or if you need more technical data.