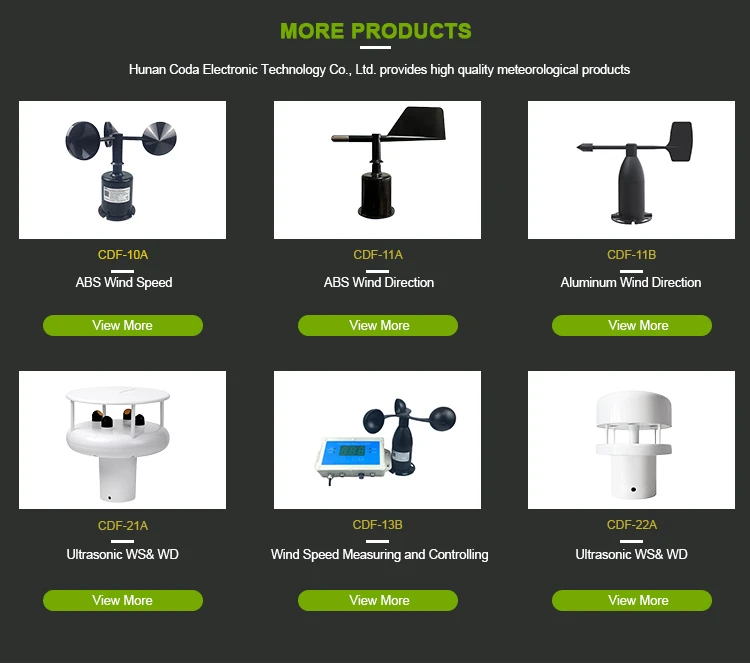

Advantages and disadvantages of ABS Plastic Anemometers and Metal Anemometers

1. Introduction

Measuring wind speed is important in weather studies, environmental checks, aerospace, and industry. It helps you make better choices. Anemometers are the main tools for this task.

They have changed in type and material over time. ABS plastic and metals like aluminum, stainless steel, and copper alloys are now the top choices.

Each material has unique properties. These properties affect how well an anemometer works, where it can be used, and its value.

This article looks at the pros and cons of different models. It looks at their physical and chemical properties. And it also looks at how well they adjust to their surroundings.

It also looks at how much they cost and what maintenance they need. It also looks at how they are used. The goal is to help researchers, engineers, and buyers pick the right models.

2. Overview of ABS Plastic and Common Metals for Anemometers

Knowing the basic features of ABS plastic and metals is key to comparing the anemometers made from them.

2.1 ABS Plastic

ABS, or Acrylonitrile-Butadiene-Styrene, is a kind of plastic. It can be shaped when it is heated.

Its three monomers give balanced properties. Acrylonitrile makes materials more resistant to chemicals and heat. It also increases surface hardness. Butadiene adds toughness, impact resistance, and low-temperature performance.

Styrene improves gloss, makes processing easier, and provides good electrical insulation. Here are the key specs: density (1.02–1.08 g/cm³), melting point (170–190°C), and tensile strength (30–50 MPa). Its high moldability allows for precise and complex parts. This is a key reason it is widely used in anemometers.

2.2 Common Metals for Anemometers

Metals are selected for their strength, stability, and long-lasting nature. The most used types are:

Aluminum alloy (6061/7075): Low density (2.7 g/cm³), strong for its weight, and resistant to corrosion. 6061 has a tensile strength of about 276 MPa.

It is great for welding and machining structural parts. 7075 has a higher strength of up to 572 MPa. It is ideal for high-performance needs, like measuring high-speed winds.

Stainless steel (304/316): Great resistance to corrosion, heat, and strong strength. 304 stainless steel contains 18% chromium and 8% nickel. It forms a protective oxide layer. It has a tensile strength of about 515 MPa.

This steel can withstand temperatures up to 870°C. It is ideal for coastal and chemical environments. 316 (with molybdenum) resists chloride better, fitting marine/offshore use.

Copper alloys (brass/bronze): Good conductivity, thermal conductivity, and resistance to wear. Brass is a copper-zinc alloy. It has a density of 8.4 to 8.7 g/cm³ and a tensile strength of 200 to 300 MPa.

Brass is easy to work with for small parts and electrical contacts. Phosphor bronze is a type of alloy. It is very flexible and can handle wear and tear well. This makes it great for precision parts like springs.

3. Advantages of ABS Plastic Anemometers

3.1 Lightweight and Easy Installation

ABS has a low density of 1.02–1.08 g/cm³. This is much less than aluminum alloy, which weighs 2.7 g/cm³.

It is also lighter than stainless steel, which weighs 7.93 g/cm³. This low density makes anemometers much lighter.

A small ABS cup anemometer weighs 200 to 300 grams. In comparison, an aluminum alloy one weighs 500 to 800 grams. This reduces the weight on supports. This makes it possible to use cheaper materials.

It also lowers the need for workers and machines. This saves time and money. This is especially true for high-rise roofs, small towers, or temporary sites.

3.2 Excellent Corrosion Resistance

ABS is very stable. It resists moisture, salt spray, weak acids, and weak bases. ABS does not corrode like metals do.

– It remains intact in coastal areas with a lot of salt spray.

– It also holds up well in mild industrial settings. Metal anemometers, like uncoated aluminum alloy, can rust. This rust can harm internal parts and lower accuracy. In contrast, ABS keeps its performance over time.

3.3 Good Impact Resistance and Durability

ABS’s butadiene component forms a rubbery phase that absorbs impact energy. In outdoor settings, strong winds can blow branches or stones. This can cause thin-walled metal anemometers to bend or crack.

In contrast, ABS only gets minor scratches or dents. It also has good resistance to fatigue. It can handle wind-induced loads and reduce failure risks for long-term outdoor use.

3.4 Low Cost and High Cost-Effectiveness

ABS pellets cost less than metal ingots or plates. Its ability to be shaped allows for mass production using injection molding. This method is efficient and makes complex parts in one step.

It also requires less post-processing compared to metal machining or welding. A medium-sized ABS anemometer costs.

This makes ABS great for large-scale use, like in weather networks and greenhouses, where keeping costs down is important.

3.5 Good Electrical Insulation

ABS has high volume resistivity, greater than 10¹⁴ Ω·cm. It also has low dielectric loss. This helps stop leaks, short circuits, and interference in internal electrical parts like sensors and circuit boards.

In thunderstorms, it helps reduce damage from lightning and electromagnetic pulses. Unlike metals, you do not need extra insulation like paint or gaskets. This simplifies design and reduces costs.

4. Disadvantages of ABS Plastic Anemometers

4.1 Poor High-Temperature Resistance

ABS has a low thermal deformation temperature between 90 and 110°C. Its melting point is between 170 and 190°C. In hot places like deserts and factories, temperatures can often go over 100°C. In extreme cases, they can reach 150°C.

This makes ABS soften or change shape. For example, the bodies of cup anemometers can bend. This bending can change inertia and reduce accuracy.

Severe cases lead to melted housings and damaged internal parts. Metals (e.g., 304 stainless steel, 870°C tolerance) perform far better here.

4.2 Low Mechanical Strength and Load-Bearing Capacity

ABS has a tensile strength of 30 to 50 MPa. This is much lower than 6061 aluminum alloy, which has a strength of 276 MPa. It is also lower than 304 stainless steel, which has a strength of 515 MPa.

It cannot handle heavy loads, like the wind or vibrations from large wind turbine nacelles. ABS structures may break or come loose, leading to failures. It also has trouble with high-altitude setups or extra weight from sensors and cables. This makes it not good for strong needs.

4.3 Poor UV Resistance and Aging

Long-term exposure to UV light breaks the bonds in ABS plastic. This leads to yellowing, brittleness, and weaker strength.

In strong sunlight, like in high altitudes, tropics, and deserts, ABS anemometers can age quickly. After 1 to 2 years, their housings may crack. The internal parts can lose toughness, which increases friction and lowers accuracy.

UV stabilizers provide only short-term protection. Metals such as stainless steel and aluminum alloy form thin, safe oxide layers. These films help them resist UV light better.

4.4 Limited Resistance to Strong Chemicals

ABS can resist weak chemicals. However, it does not stand up to strong acids like concentrated sulfuric or nitric acid. It also cannot handle strong alkalis such as concentrated NaOH. Additionally, solvents like acetone and toluene can damage it.

These can cause swelling, breaking down, or dissolving. For example, concentrated sulfuric acid can destroy the structure of ABS.

In chemical plants and labs with strong chemicals, ABS anemometers break down quickly. 316 stainless steel resists most strong chemicals. The only exception is high-temperature oxidizing acids.

5. Advantages of Metal Anemometers

5.1 Excellent High-Temperature Resistance

Metals have far higher heat tolerance than ABS. 304 stainless steel has a melting point of about 1450°C. It can handle short-term temperatures of 870°C. The thermal deformation temperature is over 500°C.

6061 aluminum alloy has a melting point of around 600°C. Its thermal deformation temperature is about 200°C. This alloy also performs better than ABS.

In deserts, where summer surface temperatures reach 60–80°C, metal anemometers stay stable. They are helpful in factories and workshops. These workshops can get hotter than 100°C.

They also work well near aircraft engines, where it can get even hotter. For example, aerospace anemometers made of titanium alloy can resist heat from air friction. ABS would deform or melt in this situation.

5.2 High Mechanical Strength and Load-Bearing Capacity

Metals have high tensile strength. For example, 7075 aluminum alloy has a strength of 572 MPa. 304 stainless steel has a strength of 515 MPa. This strength allows them to support heavy loads.

Wind turbine nacelle anemometers can resist strong winds and vibrations. High-altitude structures can hold more weight without being harmed. This reliability makes metals essential for high-stress scenarios like aerospace or large-scale energy projects.

5.3 Good UV Resistance and Longevity

Metals resist UV aging. Stainless steel and aluminum alloys create thin oxide films. These films do not harm performance.

They work well for many years outside, even in bright sunlight. Metal anemometers last longer than ABS, which only lasts 1 to 2 years in UV service. This means you will replace them less often, saving money in the long run.

5.4 Strong Resistance to Strong Chemicals

Stainless steel (especially 316) resists most strong chemicals. It can resist strong acids and bases, except for high-temperature oxidizing acids. It is ideal for chemical plants and marine areas with harsh materials.

Copper alloys can resist some chemicals. This makes metal anemometers useful in corrosive industrial settings.

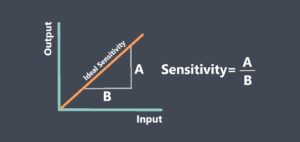

5.5 High Measurement Accuracy and Stability

Metal parts have exact machining tolerances and low thermal expansion. This is different from ABS, which has high expansion. This provides a steady structure and allows for flexible rotation, even when temperatures change.

For example, the metal cups of cup anemometers hold their shape. This keeps inertia steady, which is important for accurate wind speed data. In aerospace and industrial quality control, metal anemometers are preferred because they are more accurate.

6. Disadvantages of Metal Anemometers

6.1 Heavy Weight and Complex Installation

Metals are very dense. For example, stainless steel has a density of 7.93 g/cm³. This high density makes anemometers heavy. A medium stainless steel anemometer may weigh 1–2 kg, vs. 300–500 g for ABS.

This needs stronger supports, like steel poles instead of plastic or light aluminum. This will raise material costs. Installation requires more workers and equipment, like cranes for high places. This increases labor and time costs, especially for temporary or hard-to-reach sites.

6.2 Higher Production and Purchase Costs

Metal raw materials, like aluminum alloy ingots and stainless steel plates, cost more than ABS. Machining includes cutting, welding, and polishing.

It is complex and takes a lot of time. This process also has high labor and equipment costs. A medium 316 stainless steel anemometer costs

This limits large-scale deployment. For example, weather networks that need many units may choose ABS to help manage their budgets.

6.3 Risk of Corrosion (Without Treatment)

Stainless steel and copper alloys resist corrosion. In contrast, regular metals like carbon steel and uncoated aluminum rust easily in moisture and salt spray.

Even 304 stainless steel can rust in areas with high chloride levels, so 316 is needed. Anti-corrosion treatments like painting and galvanizing cost money and require regular maintenance. If you ignore them, corrosion can damage parts and lower accuracy.

6.4 Poor Electrical Insulation

Metals conduct electricity, so their housings and parts need extra insulation. This can include paint or seals. This helps stop leaks, short circuits, and interference from electromagnetic waves. This makes design harder and raises production costs.

In thunderstorms, metal anemometers can be damaged by lightning. To keep them safe, you need extra measures like grounding and surge protectors. This also means there will be more maintenance work.

7. Application Scenarios and Selection Guidelines

7.1 Suitable Scenarios for ABS Plastic Anemometers

Mild environments include urban weather, agricultural greenhouses, and indoor industrial areas. These places have stable temperatures and no strong chemicals or UV light.

Cost-sensitive, large-scale deployment: Meteorological observation networks, environmental monitoring stations, or temporary measurement sites.

Low-load, easy-install locations: High-rise roofs, small towers, or portable measurement equipment.

7.2 Suitable Scenarios for Metal Anemometers

Harsh environments: Deserts (high temp), coastal/marine areas (salt spray), chemical plants (strong chemicals), or aerospace (extreme conditions).

High-strength, high-accuracy needs: Large wind turbines, aircraft engines, or industrial quality control (where load/resilience matter).

Long-term outdoor use: This includes remote weather stations, offshore platforms, or monitoring infrastructure. These should last over 10 years.

7.3 Key Selection Factors

Environment: Temp, humidity, chemical exposure, and UV intensity determine material tolerance.

Load/Accuracy: High loads or precision needs, like in aerospace and energy, require metals. For low loads and cost focus, such as in agriculture, ABS is a better choice.

Budget/Lifespan: Short-term, low-cost projects choose ABS; long-term, high-investment projects prefer metals.

Installation Conditions: Hard-to-access or temporary sites benefit from ABS’s lightweight; stable, high-load sites use metals.

8. Conclusion

ABS plastic and metal anemometers each have distinct strengths and limitations. ABS is great for lightweight, low-cost, and mild environments. Metals work well in high temperatures. They are strong and can deal with hard conditions.

Selection must align with specific environmental conditions, performance needs, budget, and installation requirements. As material technology improves, like UV-resistant ABS and corrosion-resistant alloys, both types will change. Their main benefits will still be important for meeting wind measurement needs in different industries.