Ultrasonic vs. Mechanical Wind Sensors

**Ultrasonic Wind Sensors**

**How They Work:**

Ultrasonic wind sensors, such as the ResponseONE™ Ultrasonic Anemometer, use sound waves to measure wind. This is done by measuring the time it takes for ultrasonic pulses to travel between transducers. Wind affects how long it takes to travel. We study these changes to find the wind speed and direction correctly.

The sensor has three main parts: transducers, a processor, and a protective case. There are usually three or four transducers. The transducers are set up in a triangle or square shape. They have two jobs: sending ultrasonic pulses and receiving them.

When the wind blows in the same direction as the pulse, travel time gets shorter. Travel time goes up when the wind blows against the pulse. The processor reads these time changes to calculate wind data. This data is sent to outside systems, such as displays or loggers.

**Advantages:**

– **High Accuracy:** Ultrasonic sensors are very good at giving precise measurements. They can detect even small changes in wind speed and direction.

– **Durability:** They have no moving parts. This means they are less likely to wear out or break down over time.

– **Fast Response:** They give real-time wind data with very little delay. This makes them great for tasks that need quick feedback.

– **Versatility Across Weather Conditions:** Ultrasonic sensors work well in tough conditions, like extreme temperatures, humidity, and rain. They can have optional heating features. This helps them do well even in very cold weather.

**Disadvantages:**

– **Higher Initial Cost:** Advanced technology often makes ultrasonic sensors cost more than mechanical options.

– **Continuous Power Requirement:** These sensors usually need a steady power supply. This can be a problem in remote areas or where energy is low.

– **Sensitive to Weather:** They are strong, but heavy rain, snow, lightning, power surges, and dust can impact readings.

– **Limited Serviceability:** Repairs or maintenance often need help from professionals. They need factory servicing and calibration in special wind tunnels. This can cause downtime and higher costs.

– **Reduced Performance at High Wind Speeds:** These sensors work well for low wind speeds. However, they might struggle to be accurate in strong winds.

Mechanical Wind Sensors

**Understanding Mechanical Wind Sensors**

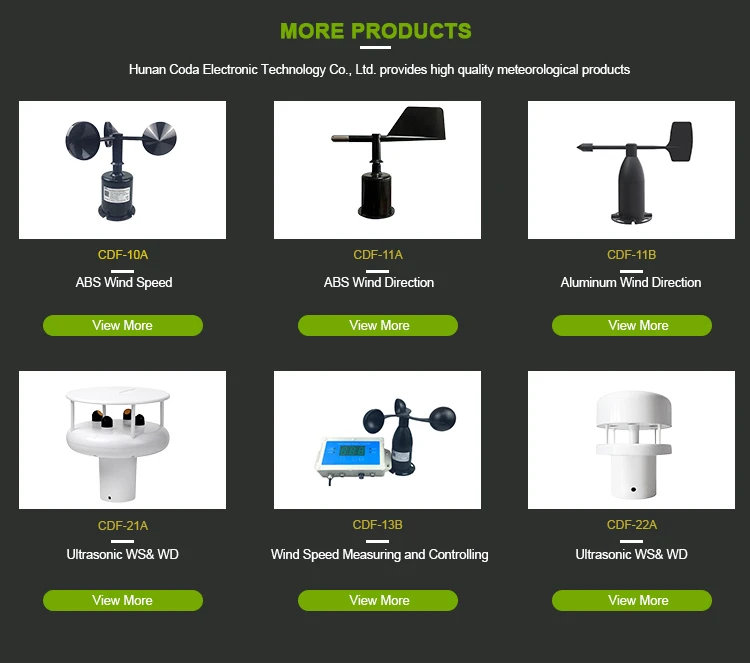

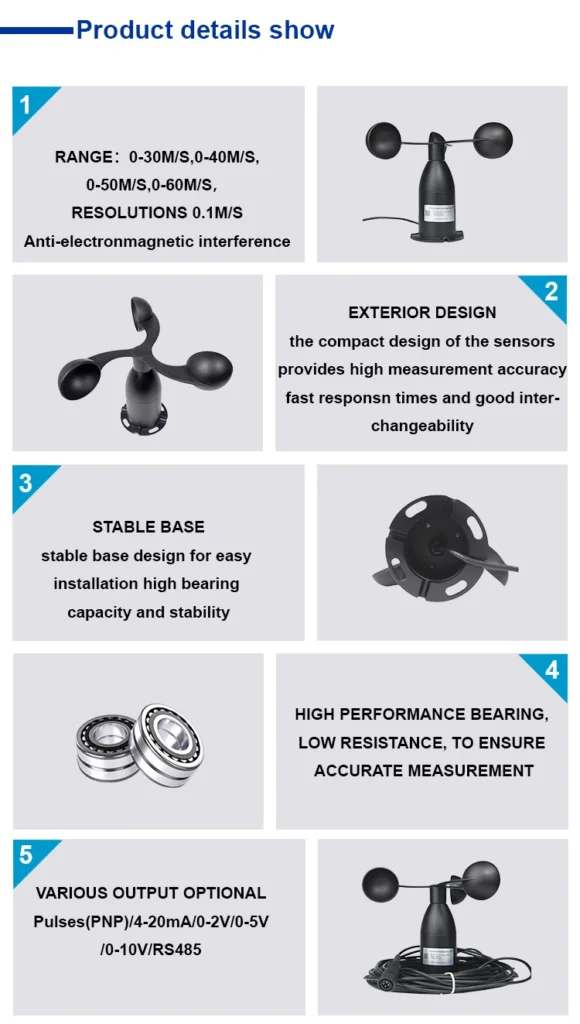

Mechanical wind sensors measure wind speed by looking at how their parts move. The two main types are 3-cup anemometers and propeller anemometers. These tools use simple mechanical principles to give reliable measurements of wind speed and sometimes direction.

When the wind blows, it moves either the cups or the propeller. This causes them to spin around a central shaft. The design keeps the rotating part in line with the wind direction. This makes sure it keeps moving.

The speed of the shaft matches the speed of the wind. A magnetic sensor or optical encoder turns this rotation into pulses. These pulses go to a processor. The processor measures wind speed by counting how many times it rotates in a certain time.

The YOUNG Wind Monitor is a popular sensor. It combines a propeller anemometer and a wind vane. This design lets the device measure wind speed. It also keeps the propeller facing the wind.

It also measures wind direction at the same time. A 3-cup anemometer needs a separate wind vane to find wind direction.

**Advantages of Mechanical Sensors**

– **Accuracy**: The Wind Monitor is one of the most precise tools in the industry. It sets the standard for agencies around the world.

– **Simplicity and Reliability**: Mechanical anemometers have a long history of being reliable. People trust them because they are easy to use and last a long time.

– **Wide Operating Range**: The Wind Monitor can measure wind speeds of over 200 mph. It is perfect for tracking extreme weather.

– **Cost-Effectiveness**: These devices are usually cheaper than ultrasonic sensors. This makes them available to more users.

– **Low Power Usage**: These sensors use very little power. They are great for remote places where energy is limited.

– **Ease of Maintenance**: Mechanical anemometers can often be serviced and calibrated by users. This means they do not need special facilities or help from the manufacturer. Simple tools, like an Anemometer Drive and Vane Angle Bench Stand, allow users to calibrate them. This process does not require a wind tunnel.

**Disadvantages to Consider**

– **Wear and Tear**: Even though moving parts can be weak, new materials and designs greatly improve how long these sensors last.

– **Environmental Challenges**: Ice, snow, or debris can build up and block rotation. This can cause wrong readings or sensor problems.

– **Higher Starting Speed**: Mechanical devices need stronger initial winds to work well. This is different from ultrasonic sensors.

**Conclusion**

Both ultrasonic and mechanical wind sensors are very useful around the world. Choosing the right device depends on what you need. Ultrasonic sensors work well in places that need fast responses to changing or low wind speeds, as long as there is enough power.

Mechanical sensors are known for being reliable and accurate. They work well in tough or fast conditions, especially when power sources are limited.

Not sure which sensor is right for you? Check out our wind sensors or contact us for help. We’re here to answer all your questions!