The Importance of Routine Maintenance for Cup Anemometer Durability and Precision

Introduction:

Regular maintenance is important for keeping cup anemometer working well. People widely use these devices to measure wind speed. These instruments have three or four cups on a rotating shaft. They are essential for meteorologists, engineers, and wind energy experts. Without regular care, cup anemometers may lose precision and face premature deterioration. This article explains why keeping these devices in good shape is important. It also lists the main maintenance practices needed to keep them working well.

The Importance of Regular Maintenance

To achieve consistent and reliable wind speed measurements, regular upkeep of cup anemometers is essential. Routine maintenance ensures optimal device functionality and allows early detection and resolution of potential issues. Here are some core reasons highlighting its importance:

1. Maintaining Accurate Measurements

Regular calibration and cleaning of cup anemometer components ensure precise readings. Accumulation of dirt, dust, or debris on the cups can hinder rotation, leading to inaccuracies. Also, harsh weather like rain, extreme temperatures, or strong winds can cause wear and tear. This can affect the device’s accuracy. Regular maintenance identifies and rectifies these problems promptly, ensuring the consistency and reliability of wind speed data.

2. Prolonging Device Lifespan

Adhering to a proper maintenance schedule significantly extends the operational life of a cup anemometer. Regular tasks can help prevent big problems. Examples include oiling the rotating shaft, checking cables for damage, and replacing worn parts. This proactive approach minimizes the need for frequent replacements, ultimately saving time and resources.

3. Enhancing Cost-Effectiveness

Not taking care of cup anemometers can lead to wrong readings and unreliable data. This can cause financial losses or poor decisions in areas that depend on wind speed measurements. By keeping up with regular maintenance, users lower the chances of sudden breakdowns or costly repairs. This makes maintenance a smarter choice over time.

4. Ensuring Safety and Operational Reliability

Regular maintenance protects the structure of anemometers. This is especially important for those on tall towers, offshore platforms, or rooftops. Ensuring that the device remains secure and operational helps mitigate risks to personnel or property arising from device malfunctions. Additionally, it supports continuous functionality with minimal downtime, providing uninterrupted data collection.

5. Meeting Industry Standards

Sectors such as renewable energy, aviation, and construction depend on highly accurate wind speed information for critical decision-making. Adhering to recognized quality standards is paramount in these industries. Routine inspections and maintenance facilitate adherence to manufacturer-recommended guidelines and industry regulations, reinforcing professional credibility while maintaining optimal accuracy and dependability.

Essential Maintenance Practices

Proper maintenance is crucial for ensuring the optimal performance and durability of cup anemometers. Here are five key practices to consistently follow for maintaining these devices:

1. **Routine Cleaning**

Accumulation of dust, dirt, or debris on the cups can increase friction, leading to measurement inaccuracies. To prevent this, routine cleaning with soft, non-abrasive materials such as brushes or cloths is essential. Use mild cleaning agents and avoid harsh chemicals that could damage the equipment. Regular cleaning not only enhances accuracy but also ensures smooth operation.

2. **Lubrication**

For seamless functionality, the rotating shaft and bearings of cup anemometers require proper lubrication at intervals recommended by the manufacturer. Adequate lubrication minimizes friction and reduces wear and tear, contributing to consistent operation. However, you should avoid over-lubrication because it may attract dust and debris, potentially causing additional issues. Regular checks and maintenance in this area are critical.

3. **Calibration**

Consistent calibration is vital to ensure precise wind speed readings over time. External factors like temperature variations, aging parts, or mechanical stress can affect calibration accuracy. Periodic adjustments using either the manufacturer’s guidelines or specialized calibration tools can maintain measurement reliability. Engaging professionals for calibration tasks can further guarantee adherence to correct procedures.

4. **Cable and Connection Inspections**

Cables and connections are susceptible to environmental exposure and mechanical stress, which could result in damage or loosening. Such issues can compromise the reliability of data collection. Routinely inspect all cables for wear, corrosion, or other damage and verify that connections are secure. Proactive identification of potential issues prevents errors due to faulty data transmission.

5. **Replacement of Components**

Wear and tear of certain parts, such as cups, shafts, or bearings, is inevitable over time. Conduct regular assessments to identify worn or damaged components. Prompt replacement not only preserves the accuracy of measurements but also improves the device’s overall lifespan.

Conclusion

By adhering to a consistent maintenance schedule, users can maximize the accuracy, reliability, and longevity of their cup anemometers. Key practices like cleaning, lubrication, calibration, cable inspection, and timely part replacement help prevent system failures and maintain functionality. These efforts are especially critical in fields like meteorology, wind energy, and construction, where precise wind data is indispensable. Prioritizing maintenance leads to dependable measurements and long-term cost efficiency.

Meeting Modern Challenges with Innovative Sensor Solutions

Environmental monitoring systems have become increasingly integral across industries, providing cutting-edge OEM sensor solutions for various applications. As we move deeper into the 21st century, technology keeps driving new services and products. These meet the changing needs of various sectors.

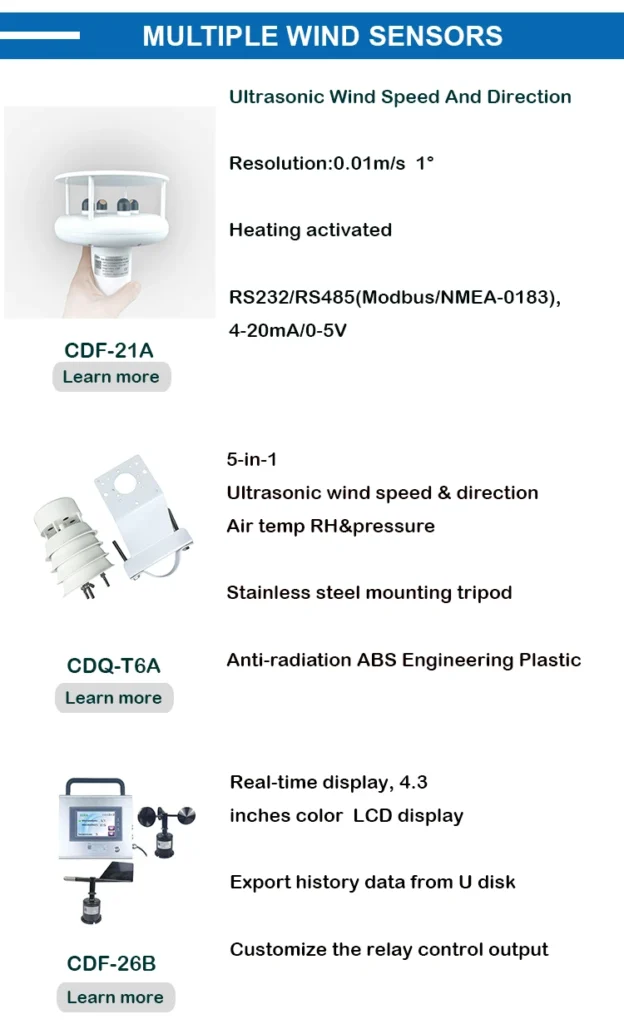

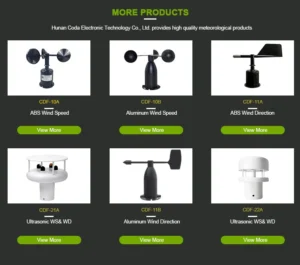

Hunan Coda Electronic Tech Co., Ltd leads this change. They shape markets with advanced sensor solutions made for specific needs. The company’s success lies in identifying challenges within target markets and delivering effective solutions that address them seamlessly.

Using advanced technologies and smart manufacturing methods has greatly improved the quality and efficiency of their sensor systems. This ensures high performance for environmental monitoring applications.