Description

CDT-14A ORP Sensor

An analog ORP sensor offers a simple and cost-effective solution for many wastewater and process uses. It has the great benefit of being an all-in-one sensor. This sensor can measure both ORP and temperature at the same time. This feature is very useful and efficient in various industrial and environmental settings.

The sensor’s design is impressive. The strong Ryton body is made for easy installation in on-line systems. It has 3/4 inch tapered threads on both ends. This makes setup easier.

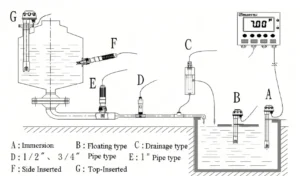

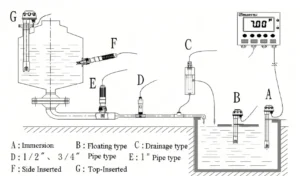

Dimnsion & Mounting

product details show

ORP Sensor communications

Application

Water treatment:

◉In drinking water treatment, ORP (REDOX potential) sensors can be used to assess the REDOX status of water quality. For example, when disinfecting, common disinfectants like chlorine gas and chlorine dioxide change the ORP value of water.

◉ORP sensors are important tools for checking water quality in wastewater treatment plants. In the aerobic treatment stage, microbes break down organic matter. This process needs an environment with oxygen. The ORP value typically ranges from +200 to +600 mV.

◉In industrial water systems, analog ORP sensors are used to stop corrosion and scaling of equipment. Dissolved oxygen and other substances in water can react with metal surfaces. This can cause corrosion. We can monitor ORP values.

Aquaculture:

◉In aquaculture ponds, ORP sensors can check the REDOX status of the water in real time. The right ORP value is one of the key factors for the success of aquaculture.

◉The REDOX potential in aquaculture water is connected to how materials move and energy flows in the ecosystem. For example, ORP values affect the nitrogen cycle in water. In aerobic conditions (high ORP), nitrification turns ammonia nitrogen into nitrate nitrogen.

In anaerobic conditions with low ORP values, denitrification can happen. This process converts nitrate nitrogen into nitrogen gas and releases it into the atmosphere.

Environmental monitoring:

◉In monitoring rivers and lakes, ORP sensors help check the health of these water bodies. ORP values relate to biogeochemical cycles in water. In eutrophic lakes, algae blooms happen. At night, algae use oxygen from the water. This lowers the oxygen reduction potential (ORP).

◉ORP values can show how surface water and groundwater interact. In some wetlands and rivers, these waters mix. This mixing changes the REDOX state of the water.

ORP Sensor News

Water Treatment Solution

Water Measurements Explained: ORP vs pH

what is an orp sensor?

Top 9 Water Quality Sensors for Water Treatment | Coda Sensor