How Wind Sensor Works

**Working Principle of Wind Speed Sensors**

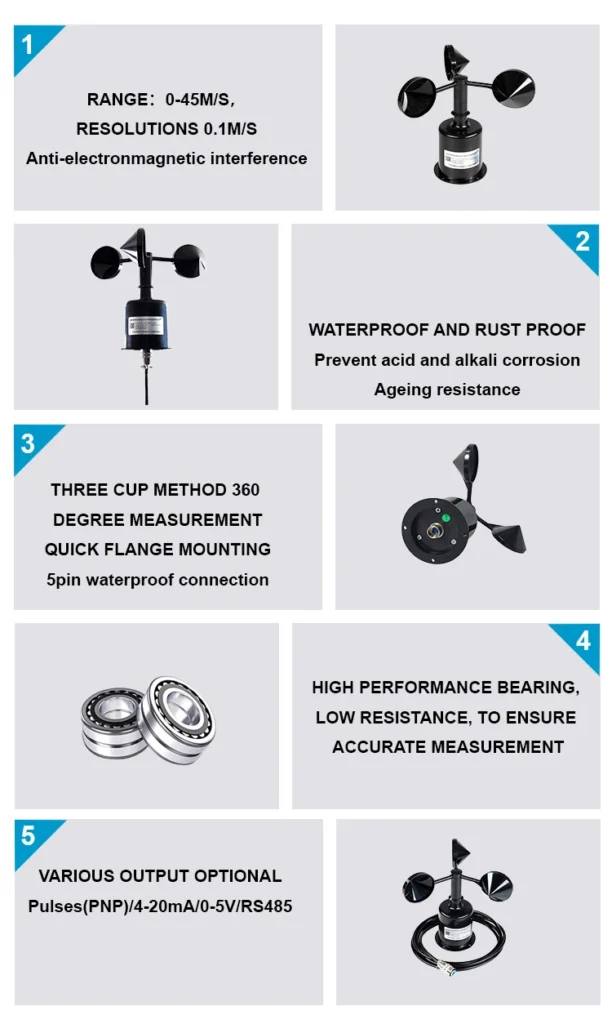

A wind speed sensor is a device that measures how fast the wind is blowing. It works by using wind to spin three cups on top of the sensor.

This rotation turns a central axis. This action turns on an internal sensor. The sensor then sends out a signal. This signal is used to measure the wind speed accurately.

**Working Principle of Wind Direction Sensors**

Wind direction sensors find out which way the wind is blowing. They use a tool called a wind vane. As the vane turns, it sends data to a coaxial encoder.

This system keeps track of where the wind vane is located. It gives the output value for the wind direction.

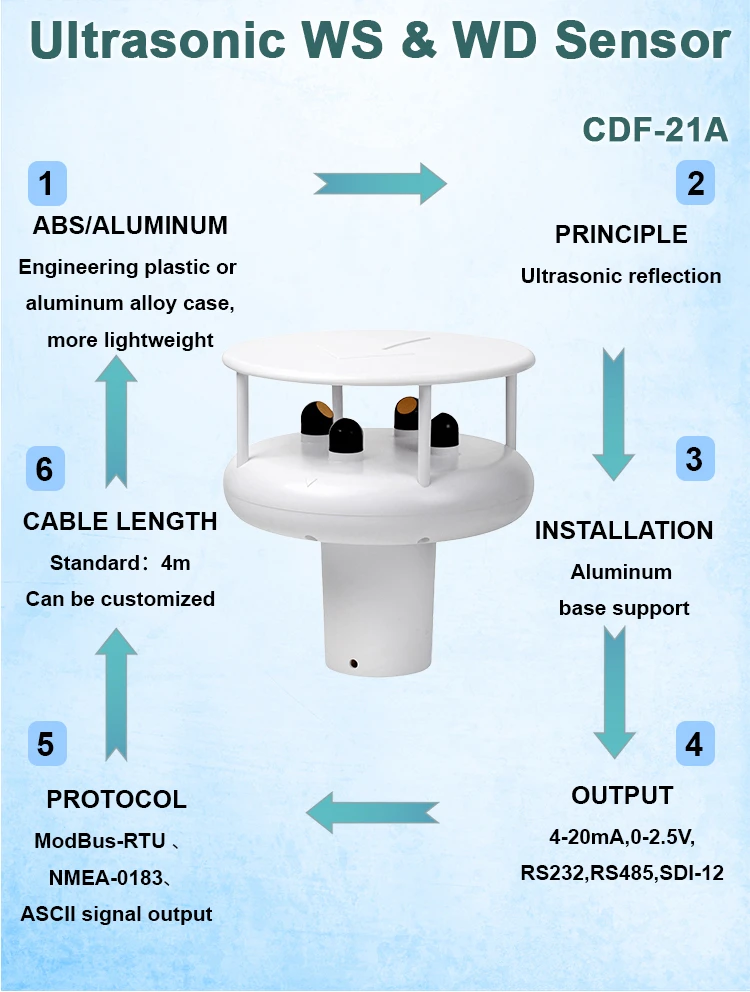

**Ultrasonic Wind Sensors**

Ultrasonic anemometers measure wind by looking at how wind changes the time it takes for sound waves to travel. These sensors have ultrasonic transmitters and receivers placed at opposite ends of a sampling area. The device measures how sound waves change as the wind speed changes along the path. It uses this data to calculate wind speed and direction.

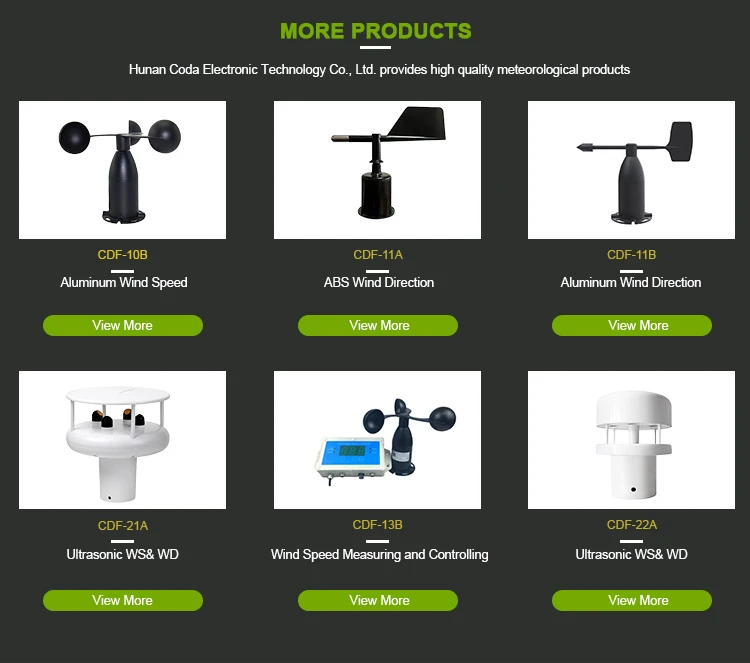

**Types of Wind Sensors**

– **Polycarbonate Wind Speed Sensor**

– **Polycarbonate Wind Direction Sensor**

– **Aluminum Alloy Wind Speed Sensor**

– **Aluminum Alloy Wind Direction Sensor**

– **Ultrasonic Wind Sensor**

– **Duct-Type Wind Speed Sensor**

– **Marine Wind Sensor**

– **Integrated Wind Sensor**

**Components of Wind Sensors**

1. **Wind Direction Sensor Components**

– **Wind Vane**: This is the key part of a sensor that shows wind direction. Its rotation comes from the movement of the bearings. This helps us see which way the wind is blowing.

2. **Wind Speed Sensor Components**

– **Three-Cup System**: This part is made of carbon fiber wind cups and a cup holder. It shows the strength of the wind blowing sideways. It uses rotational motion to produce frequency signals. These signals are then interpreted as wind speed.

– **Multi-Tooth Rotor and Slit Optocoupler**: This converter lets signals pass while the cup spins in the optocoupler.

– **Precision Potentiometer**: This device is in some models. It uses variable resistance to improve accuracy in different conditions.

**Operational Challenges Associated with Wind Sensors**

Wind sensors can face issues. These include calibration drift, damage from the environment, and interference from dirt or debris.

Maintenance is important for keeping accuracy over time. This is especially true in tough environments or marine areas. In these places, corrosion and mechanical strain are more likely to happen. New materials like polycarbonate and aluminum alloy have made products stronger and better in different conditions.

Wind sensors can face different problems while in use. These issues can affect how well they work and how reliable they are. Here is a clear look at common problems with wind sensors:

**Wind Speed Sensor Issues**

*Inflexible Rotation or Being Stuck*

This issue may occur with both new and old wind speed sensors, though the causes differ.

– **For new wind speed sensors:** The problem often happens because loose parts affect how the bearing rotates. To fix this, turn on the sensor to check the wind speed. If it does not work, please contact the manufacturer for a replacement.

Also, manually turn the wind cup at the top of the sensor. If it does not spin smoothly, there may be a connection problem inside the device. This can be fixed with help from a technician.

– **For older sensors:** Reduced sensitivity may come from things blocking the sensor. This can include debris or clutter like leaves, ice, or tilt problems.

Even a small feather stuck on the wind cup can cause big errors in readings. Begin by cleaning the sensor surface. Also, remove any nearby obstacles.

If the problem still happens after you remove outside blockages, take the sensor apart. Clean any dirt or debris inside. This includes small gravel that may be stuck in the shaft from sandy or windy conditions.

Regular maintenance and cleaning are important. They help the sensor work well and last longer. Be aware that using it for a long time may cause internal parts to age or come loose. In these cases, you may need to replace worn-out parts or buy a new sensor.

*Reading Shows Wind Speed as Zero*

There are three main reasons why a wind speed reading might show zero:

1. **Reed Switch Failure:**

The reed switch in the device might not be working properly. A light tap on the top part of the anemometer can sometimes make it work again for a short time. However, this problem needs a professional to replace it to stop it from failing again.

2.**Damaged Cable or Intermittent Contact:**

Damaged cables can lead to poor contact between the internal wires. This can lead to wrong speed readings. To fix this, check the cable, power system, and all connections for problems.

Using a backup device, rotate the wind shaft manually. If the rotation is smooth and quiet, it shows that the rotating mechanism is working normally. Check if readings are generated. If the data is wrong or missing, the sensor might be broken and needs to be replaced.

3. **High Starting Wind Speed Threshold:**

This issue occurs, but it is rare. It happens when the natural wind speeds are below the sensor’s minimum activation level. In these cases, move the sensor to places with stronger winds. You can also measure at different times and conditions to get accurate readings.

There is a clear difference between the wind speed sensor readings and those from other anemometers. Users often do not ask how accurate their anemometer results are. Some issues can cause low-speed readings.

The most common problem comes from a stiff bearing in the wind cup shaft. You can fix this by following the guidelines given. Another option is a broken reed switch. This could disrupt the connection and cause problems with other anemometer readings.

Wind speed measurements can change based on how high you are. Any two wind speed sensors should be installed at the same height and in the same conditions. This will help ensure they collect uniform data.

Also, there is another factor to think about: wind does not blow at a steady speed. This is especially true in areas away from the coast. Wind often changes speed quickly, with short bursts of stronger and weaker gusts.

Wind speed sensor makers use different ways to measure. This causes differences in their reading ranges. As a result, the values obtained from different sensors are generally not directly comparable.

**Issues Related to Wind Speed Sensor Connections**

Wind speed sensors with Modbus output can have problems due to poor wiring connections. This means a circuit inspection is needed. In 4-20mA sensors, connection problems can happen due to loose terminal connections or issues with the wires.

For wind speed sensors that are connected to a network, the main problem could be an unstable network. This can cause signal interruptions or instability.

**Wind Direction Sensor Problems**

**Sticking Wind Vanes:**

If you see that the wind vane on a new sensor is stuck when you turn it by hand, this means there is a problem. It might be a broken sensor or a bearing that is not working right.

Contact the manufacturer to replace the unit. If the device is connected and powered, but the vane does not move, replace the sensor. You can also contact the manufacturer for help. Do not take apart the sensor unless you are skilled in using wind direction tools.

If a working sensor gets stiff over time, it is usually due to worn-out parts. This can happen due to poor maintenance or long use. In these cases, think about replacing important parts or cleaning the inside after carefully taking the unit apart.

**Intermittent Wind Direction Readings:**

An issue with inconsistent readings may come from wiring problems. These often happen due to poor connections between the acquisition device and the equipment. Technicians call this a “signal open circuit.”

An open circuit happens when no current flows between two points. This can be due to a broken wire or a wire with very high resistance. This situation can cause outside interference and wrong data outputs. Check this problem by carefully looking at the connectors and wires.

**Wind Direction Value Displaying Zero:**

First-time users may notice that the wind direction sensor shows a value of zero. To address this, rotate the wind vane manually. If the value changes, the vane will point in the direction of the wind. The reading shows which way the wind is blowing.

If the reading stays at zero after you rotate it, check the cables and power supply for issues. If both are working, it’s likely that the sensor has internal damage. You will need to replace or repair it.

The azimuth reading for the wind direction is inaccurate.

First, make sure the wind direction sensor is aligned. The “N” marker must point straight to true north when you install it. If the sensor is not aligned correctly, it can give wrong wind direction readings.

Next, use a backup device to connect and test the wind vane. Manually turn the vane. Check that the wind direction indicator shows a value of 239°.

If it does, this shows that the sensor is working properly. Next, check other parts to see if they are working properly.

If the wind direction indicator does not show 239° or keeps changing, it could mean that some parts of the sensor are broken. These parts are called infrared light-emitting diodes. In these cases, you should inspect and make repairs.

Also, use a wind direction and speed calibrator. This will help check how well the wind direction sensor works and fix any issues.