What is the types of ph sensors and Applications?

Choosing the right water quality sensor is important for accurate measurements in water monitoring systems. The pH sensor is especially important. However, there are many pH meter options on the market. This makes it hard for users to find the best choice.

Questions like “How do I choose the right pH sensor?” and “Where should I start?” often come up. To answer these questions, you need to know the basics of pH meters before buying or using them. This article gives an overview of the different types of pH sensors and where they can be used. This will help you make a good decision.

What is a pH Sensor?

A pH sensor measures how much hydrogen ion activity are in a solution. It then converts this information into a useful signal. Typically, it has two main parts: a chemical detection part and a signal transmission part.

The pH scale goes from 0 to 14. A pH of 7 means the solution is neutral. Values above 7 show more alkalinity. Values below 7 show more acidity.

We use these sensors a lot in industry. They help us analyze solutions and monitor water quality.

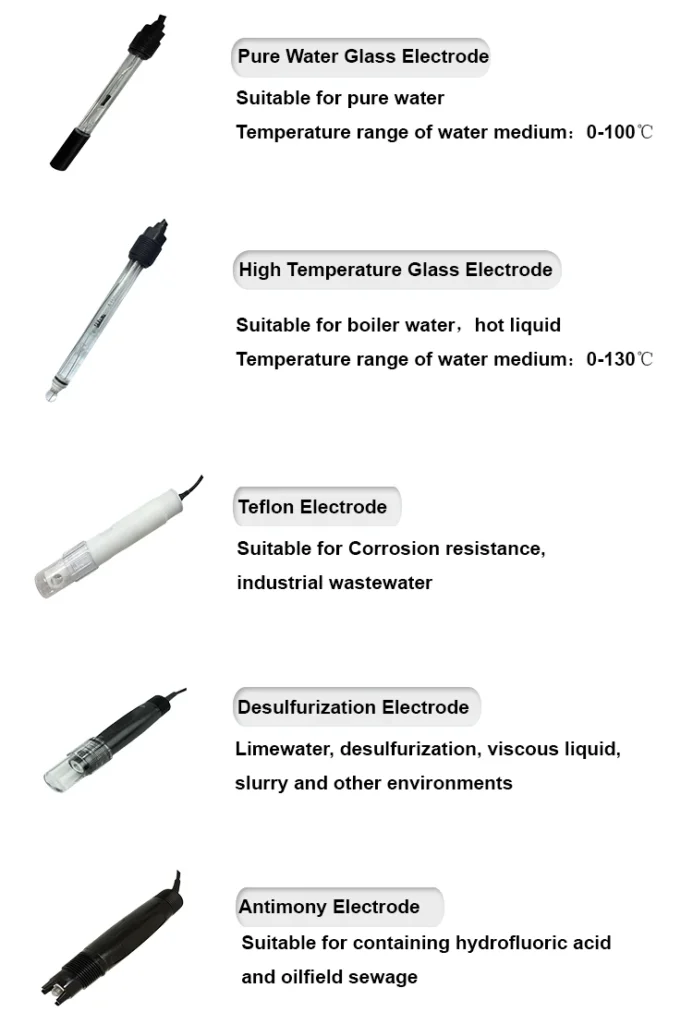

Types of pH Sensors for Water Quality Applications

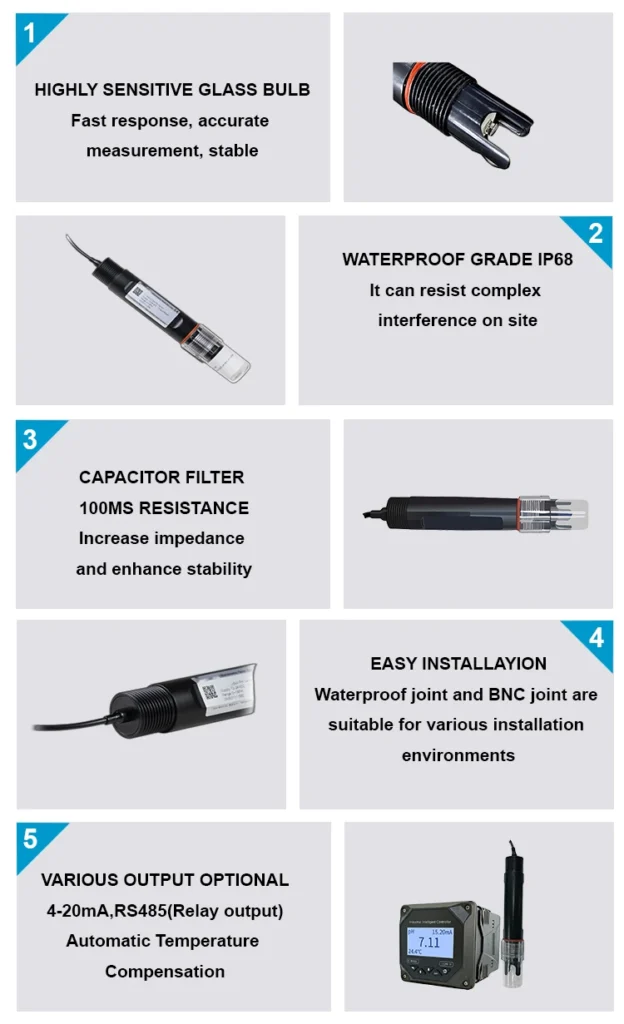

The success of your project relies on picking the right pH sensor for its environment. A good choice boosts measurement accuracy and cuts costs. On the other hand, a bad sensor can lead to errors, harm electrodes, and increase expenses. Here are six common types of pH meters and their uses:

1. pH Composite Sensor

The pH composite sensor combines a glass ph electrode with a reference electrode in one unit. Its outer shell can be made of plastic or glass. This design makes it easier to use by combining two parts into one.

**Characteristics:**

– **Detection Range:** 0-14 pH

– **Applications:** Used in places with weak acids or weak bases, like industrial wastewater, home sewage, farming, and fish farming.

– **Maintenance Note:**

Soak the pH composite sensor in a pH4 buffer.

Make sure to use potassium chloride (KCl) during the soaking process. This helps prepare the glass bulb and liquid junction for the best performance.

Be careful not to soak the electrode in deionized water. Do not soak it in regular pH4 buffer either. This is different from how traditional glass type of electrode were often treated.

Using old or wrong instructions can lead to less accuracy and slower response times for the ph measurement electrode. Over time, using the wrong soaking methods can hurt performance. This happens because it lowers the KCl hydrogen ion concentration at the liquid junction’s boundary layer. As a result, the junction potential becomes unstable.

2. Desulfurization pH Sensor

Engineers create the desulfurization pH sensor to measure pH in flue gas desulfurization. It has a gel electrode that needs no maintenance. This design offers high precision. It works well in high-temperature and high-pH conditions.

Its flat design prevents scaling and makes cleaning simple. This is great for slurry and desulfurization uses. The sensor has a PTFE liquid junction that resists blockages. This feature allows for long-term online testing.

**Specifications and Applications**

– Detection Range: 0–14 pH

– Application: Industrial wastewater, water treatment, mineral suspensions, and measuring pH in flue gas desulfurization.

The sensor performs very well in wet flue gas desulfurization. This is due to its solid-state liquid junction design. This design avoids issues like liquid junction blockage and reference pollution.

It also stops sulfur poisoning and protects the reference electrode. The wear-resistant pH bulb gives accurate signals. It also works well in high-density and fast-flowing limestone slurries.

**Maintenance Notes**

– If the electrode membrane dries out, soak it in a neutral standard solution. If you can, use a 3M KCl solution. Leave it in the solution for 24 hours.

– KCl crystals can form around the electrode cap during transport and storage. You can wash them off with water.

– Always keep the membrane moist and store the electrode with 3M KCl solution in its protective cap. Do not use deionized, distilled, or pure water for storage.

3. PTFE pH Sensor

This sensor is made from polytetrafluoroethylene (PTFE). It is very resistant to strong acids, alkalis, and corrosion. This makes it good for use with organic substances.

The sensor has a special glass film that is low-impedance. This film helps it resist wear and improves accuracy. A protective ring goes around the front probe. This makes it more durable and ensures accurate and consistent measurements.

**Specifications and Applications**

– Detection Range: 0–14 pH

– Application: Industrial wastewater can be treated by neutralizing acids and bases. This is important in cases of severe contamination. It is also crucial in environments with strong acids or bases.

**Usage and Maintenance Guidelines**

1. Before measuring, rinse the sensor with distilled or deionized water. Then, gently blot the moisture with filter paper. This helps prevent contamination. Make sure to submerge both the electrode bulb and liquid junction in the solution at the same time.

2. After use, clean the sensor. Store it in a saturated potassium chloride solution with a protective cover. You can also submerge it in a container filled with the same solution.

3. Keep the terminal dry and clean. If needed, use alcohol to clean it. Let it dry before using.

4. Stay away from long exposure to distilled water or protein solutions. Also, avoid contact with silicone grease.

5. If the glass membrane turns cloudy or gets deposits, clean it with diluted hydrochloric acid. Then rinse it with water.

6. It is important to clean and calibrate the instrument regularly. This helps keep it accurate.

4. Electroplating pH Sensor

This sensor has a double liquid junction design. This design helps reduce contamination from the reference liquid. The longer diffusion path makes it more durable in tough environments. Engineers designed it for easy maintenance and a longer service life.

**Specifications and Applications**

– Detection Range: 0–14 pH

– Application: Sewage treatment, monitoring wastewater from electroplating, fermentation processes, and solutions with a lot of organic content.

5. pH Glass Sensor

The pH glass sensor uses a saturated calomel electrode as a reference. It also uses a glass electrode as an indicator. Together, they form a working battery with the water sample being tested.

A pH meter measures the potential difference. This gives quick and accurate pH readings. Factors like water turbidity, color, salinity, colloids, oxidants, or reducing agents have little effect on this sensor. This ensures reliable results in different conditions.

Glass electrode

**Detection range:** 0–14 pH

**Applications:** This is good for biological engineering, pharmaceuticals, brewing, chemical reactions industries, semiconductor electronics, or places with corrosive conditions.

Maintenance of a pH Sensor

Proper maintenance is important for keeping sensors working well and making them last longer. Without regular care, problems can happen. These problems include oily coatings, blockages in reference contacts, damaged pH bulbs, and shorter electrode life from reference poisoning.

– If your electrode regularly encounters oily residues or similar coatings, consider using a sensor equipped with a non-porous reference junction. These sensors reduce maintenance needs when used with automated cleaning systems.

– You can reduce clogging of reference junctions by using a non-porous electrode.

– For fragile pH bulbs that can break when touching things like sewage, use protective bulb guards.

– We can mostly fix reference poisoning problems by using non-porous electrodes.

Cleaning a pH Sensor

Here are steps to clean and take care of your pH electrode:

1. Always wear safety gloves and glasses when handling electrodes. Store unused electrodes in a proper liquid solution. If electrodes dry out, they will not work.

2. Electrodes are usually shipped in saline solution. They should stay stored in this solution for future use.

To clean the electrode:

1. Soak it in a solution with 95% water and 5% hydrochloric acid.

2. Soak it for 5 to 10 minutes to dissolve the residue or coating. Rinse it well afterward.

3. If a lot of buildup remains, repeat this process several times as needed.

4. Use a soft cloth to gently wipe the sensor after cleaning. Avoid rough materials that can harm the electrode.

Why are different types of pH sensors important?

Different types of pH meters are important for keeping an eye on water quality. This task is becoming more essential as water pollution increases. Since protecting the environment and managing water resources are important issues, countries worldwide are paying more attention to them.

In some cases, economic development in industrialized countries has harmed environmental sustainability. Industry is the backbone of these economies. This trade-off has increased water pollution. It is now a major issue that needs immediate attention.

In this context, sewage treatment technology has developed. It treats domestic and industrial wastewater effectively. This prevents pollutants from entering water bodies. A key part of these systems is the pH sensor.

The pH value is a key factor in testing water quality. In natural water, the pH is usually between 6 and 9. For drinking water, the best pH range is 6.5 to 8.5.

Some industrial waters have stricter rules. The best pH range is 7.0 to 8.5. This helps stop corrosion of metal equipment and pipes. pH shows how acidic or alkaline water is.

It is different from measure the acidity and alkalinity, which measure the amounts of acid or alkali. Any big changes in pH levels can show water pollution.

conclusion

Extreme pH levels can harm aquatic ecosystems. They can kill organisms in the water. pH also affects dissolved oxygen levels. It influences how toxic chemicals and heavy metals are.

Most aquatic species thrive in a pH range of 6.5 to 9.0. However, some species can tolerate more extreme conditions.

Combination ph sensors are very important in many areas like industry, fish farming, farming, and sewage treatment. They help monitor and control pH levels. This ensures safety and stability in processes that involve liquids. Choosing the right type of pH meter for each application is essential to meet different needs effectively.