Understanding Temperature Data Loggers

In many industries and scientific research, it is very important to monitor and record temperature accurately. This is where temperature data loggers come into play.

These devices measure and record temperature data for a set time. They provide useful information for many different uses. In this article, We will cover their parts, types, uses, and benefits.

What is a Temperature Data Logger?

A temperature data logger is a special electronic device. It measures and records temperature data at set times. It has several important parts that work together to make sure data is collected accurately and reliably.

Components of a Temperature Data Logger

Temperature Sensor:

The temperature sensor is the main part of the data logger. It detects and measures the surrounding temperature. There are many types of temperature sensors. Each type has its own benefits and uses.

Thermocouples:

Thermocouples are widely used temperature sensors that consist of two different metals joined together. When there is a temperature difference between the two ends of the thermocouple, it creates a voltage.

This voltage can be measured and linked to the temperature. Thermocouples are known for their wide temperature range. They have a fast response time and are relatively low in cost.

Resistance Temperature Detectors (RTDs) work on the idea that a metal’s electrical resistance changes with temperature. Platinum RTDs are the most common type. They provide high accuracy and stability. They are often used in places that need precise temperature readings, such as labs and factories.

MPU:

The MPU is the brain of the data logger. It processes data from the temperature sensor. It controls the sampling rate and stores the data in memory.

The MPU lets you talk to outside devices like computers or mobile phones. This makes it easier to transfer and analyze data.

Memory:

A temperature data logger needs enough memory to save the recorded temperature data. The amount of memory needed depends on several factors.

These include the sampling rate, the recording duration, and the data resolution. Some data loggers have built-in memory. Others can use memory cards to get more storage space.

Power Source:

Data loggers can get power from different sources. These include batteries, USB ports, or external power supplies. Battery-powered loggers are easy to use. They are great for tasks that need portability and remote monitoring.

They often use batteries that last a long time. This helps them run for many hours. USB-powered loggers are great for places where power is easy to reach, such as labs or offices.

External power supplies are often used for setups in fixed places. They offer a steady and dependable power source.

Display and User Interface:

Some temperature data loggers have a built-in display. This lets users see the current temperature, the sampling rate, and other important details.

The user interface may have buttons or a touchscreen. These help set up the data logger. You can adjust the sampling interval, start and stop times for recording, and the data storage format.

Communication Interfaces:

Modern temperature data loggers use different ways to communicate. These help move data to outside devices. Common ways to connect devices include USB, Bluetooth, Wi-Fi, and Ethernet.

Users often use USB connections to link the data logger to a computer. This allows for data download and analysis.

Bluetooth and Wi-Fi let you transfer data wirelessly. This makes it easy to get data from a mobile device or a remote place. Ethernet interfaces are good for applications that need a fast and reliable network connection. This is important in industrial monitoring systems.

Types of Temperature Data Loggers

Data loggers come in various types. Each type is made for specific needs and uses. Here are some common types data loggers:

1. Stand – Alone Temperature Data Loggers

Stand-alone temperature data loggers are devices that work on their own. They do not need to connect to a computer or any other device to work. They are typically battery – powered and have a built – in memory for storing the recorded temperature data.

You can use stand-alone loggers and put them where you want to check the temperature. After the recording is done, you can download the data to a computer. Use a USB cable or another way to connect.

Stand-alone temperature data loggers are often used to keep track of food and drinks. They also watch over medicines and check the environment.

2. Wireless Temperature Data Loggers

Wireless data loggers use wireless technologies like Bluetooth, Wi-Fi, or cellular networks. They send recorded temperature data to a receiver or a cloud platform.

This removes the need for physical connections. It allows for real-time monitoring and remote access to the data. Wireless loggers are very helpful in situations where running cables is hard or not practical.

They are also great for continuous monitoring. In big warehouses or factories, workers can put wireless temperature data loggers in various places. They monitor the temperature in real-time.

Facility managers and quality control staff can access the data from a distance. Wireless loggers are often used in healthcare places like hospitals and clinics. They help keep track of the temperature in medical refrigerators and freezers.

3. USB Temperature Data Loggers

USB data loggers are compact devices that connect directly to a computer’s USB port. The USB port powers them, so they do not need an external power source. You can easily set up and use USB loggers, and you can quickly download the data to the computer for analysis.

These loggers are often used where a simple and cheap solution is needed. This includes small labs, classrooms, or home experiments. USB temperature data loggers are good for situations where data must go straight to a computer. This allows for quick processing or reporting.

4. Multi – Channel Temperature Data Loggers

Multi-channel temperature data loggers can measure and record temperature from several sensors at the same time. They have several input channels. Each channel can connect to a different temperature sensor.

Multi-channel loggers are helpful when you need to check the temperature in different places or points in a system. In a big industrial process, engineers can place many temperature sensors at different stages.

This helps track temperature changes. A multi-channel temperature data logger can gather and save data from all the sensors.. This gives a complete view of the temperature profile.

Researchers often use multi-channel loggers in environmental monitoring. They can monitor the temperature in different parts of a building. They can also check the temperature in various water bodies in a river system.

Applications of Temperature Data Loggers

Temperature data loggers find applications in a wide range of industries and fields. Here are some of the key applications where data loggers play a crucial role:

1. Food and Beverage Industry

In the food and drink industry, it is very important to keep the right temperature in the supply chain. This helps ensure the safety and quality of the products.

People use temperature data loggers to check the temperature when storing, transporting, and distributing food and drinks. They help keep food and other items fresh by maintaining the right temperature. This stops food from going bad and keeps harmful bacteria from growing. In a cold storage facility, you can install it.

They will keep an eye on the temperature in the storage rooms all the time. If the temperature goes above the set limits, an alert can be sent to the manager. This lets them take action right away.

Temperature data loggers are used in food processing plants. They check the temperature while cooking, baking, and doing other tasks. This helps make sure the product is good and stays the same.

2. Pharmaceutical and Healthcare Industry

The pharmaceutical and healthcare industry has strict rules for storing and transporting drugs, vaccines, and other medical products. Temperature data loggers keep products stored and transported at the right temperatures.

This keeps them effective and safe. In a drug warehouse, workers set up temperature loggers. These loggers help monitor the temperature in the storage areas.

Data loggers track the temperature during transport in vehicles that control the temperature. The data from these loggers can help with quality control. They can also assist with compliance reports and product recalls if needed.

Temperature data loggers are used in hospitals and clinics. They check the temperature of medical refrigerators, freezers, and incubators. This helps ensure that we store medications and biological samples properly.

3. Environmental Monitoring

Temperature is an important factor in environmental monitoring. Researchers use temperature data loggers to check the temperature of air, water, soil, and other parts of the environment.

They help us learn about climate change. They also look at how people affect the environment. Plus, they check the health of ecosystems.

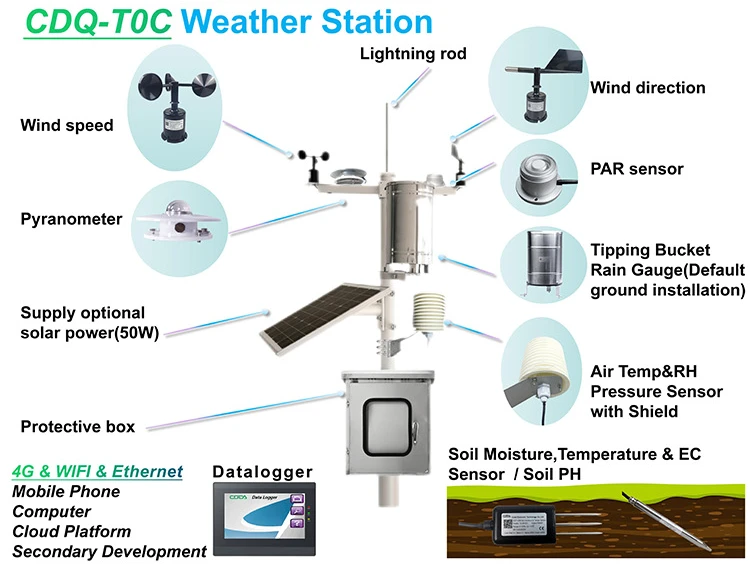

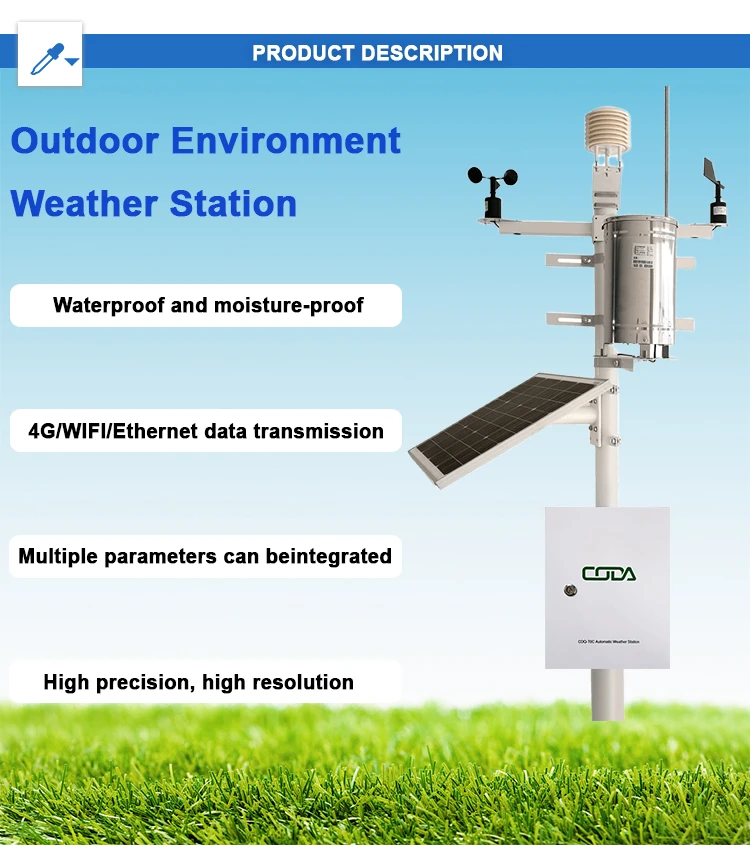

For example, a weather station uses temperature loggers. These loggers record the air temperature at regular times. These data are used to create weather forecasts and climate models. In a water quality project, temperature loggers measure water temperature.

They can be used in rivers, lakes, and oceans. Changes in water temperature can affect the aquatic life and the overall health of the water body. Farmers use temperature data loggers to check the temperature of the soil and air around crops. This helps farmers improve their irrigation and manuring schedules.

4. Industrial Processes

In many industrial processes, temperature control is critical for ensuring product quality, process efficiency, and equipment reliability.

Operators use temperature data loggers to monitor and record the temperature at various stages of the industrial process. In a manufacturing plant, you can install temperature data loggers on equipment like furnaces, ovens, and reactors.

They help keep track of the temperature while things are being made. If the temperature goes outside the set limits, it can harm the product’s quality or cause equipment to fail. Operators can keep track of the temperature using data loggers.

This helps them take quick actions to keep the process stable. Temperature data loggers are used in energy production places, such as power plants. They check the temperature of engines, turbines, and other machines. This helps ensure efficient operation and prevents overheating.

5. Research and Development

In research and development (R&D), researchers often need accurate temperature measurement and recording for their experiments and studies.

Researchers use temperature data loggers in many fields. These fields include chemistry, biology, physics, and materials science. You can use temperature data loggers in a chemical reaction experiment.

They help keep track of the temperature change during the reaction. This information can help researchers understand how reactions happen and improve the reaction conditions.

In a biology experiment, temperature data loggers can track the temperature of cell cultures or animal homes.

Keeping a stable temperature is important for the growth and survival of cells and living things. Temperature data loggers are used in materials testing. They help study how temperature affects materials. This includes their strength, conductivity, and durability.

Benefits of Using Temperature Data Loggers

The use of temperature data loggers offers several benefits in different applications:

1. Accurate and Reliable Data

Temperature data loggers are made to give accurate and reliable temperature readings. They adjust the instruments to make sure the recorded data is within the correct accuracy range.

Using high-quality temperature sensors and smart data processing helps reduce errors and keep the data accurate. This accurate data is important for making smart choices in many fields. These include food safety, drug quality control, and environmental monitoring.

2. Continuous Monitoring

Temperature data loggers can work for long times. They record temperature data at regular intervals. This ongoing monitoring helps detect any changes in temperature or unusual patterns that may happen over time.

In situations where it is important to keep a stable temperature, data loggers are helpful for storing sensitive products. They provide real-time information about temperature conditions. This allows for quick action if needed.

3. Data Traceability and Compliance

In many industries, there are strict rules about temperature control and keeping records of data. Temperature data loggers provide a means of data traceability, allowing companies to demonstrate compliance with these regulations.

You can use the recorded temperature data for auditing purposes, quality control, and product recall investigations. By keeping accurate temperature records, companies can follow the required standards and rules. This helps keep their products and services safe and of good quality.

4. Cost – Efficiency

Using temperature data loggers can lead to cost – savings in several ways. By keeping an eye on the temperature, companies can find and fix temperature-related problems early.

This helps prevent serious damage or loss. In a food storage facility, finding a temperature rise early can stop food from spoiling. This saves money by reducing waste.

Using data loggers can cut down on the need for manual temperature checks. These checks can take a lot of time and effort. This automation of temperature monitoring can help employees focus on other important tasks. This will improve overall productivity.

5. Remote Monitoring and Access

Wireless and cloud – enabled temperature data loggers allow for remote monitoring and access to the temperature data. This is especially helpful in situations where the data logger is in a remote or hard-to-reach place.

Facility managers or operators can access real-time temperature data from anywhere. They can use a computer, tablet, or smartphone with an internet connection. This remote access allows for quick decision-making. Users can respond fast to temperature issues, even if they are not at the data logger’s location.

Conclusion

Temperature data loggers are important tools. They help measure, record, and monitor temperature in many different situations.

Their parts, types, and uses are varied. They meet the specific needs of different industries and scientific research. Temperature data loggers are very important. They help keep food and medicine safe and of good quality.

They also watch the environment, improve industrial processes, and help with research and development. Using temperature data loggers has many benefits.

They give accurate data and allow for constant monitoring. They also ensure data traceability and save money. Plus, they let you access data remotely.

These features make data loggers very useful for managing environments and processes that need careful temperature control. As technology keeps advancing, temperature data loggers will likely become more advanced. They will offer better features to meet the changing needs of different sectors.