Float level sensor advantages and disadvantages

Introduction to Level Sensors:

In many fields like water treatment, manufacturing, and oil and gas, it is important to keep accurate liquid levels. This helps with efficiency and safety. Level sensors play a key role here. They help measure and manage liquid levels precisely.

This article talks about three common types of level sensors: float sensors, conductivity sensors, and ultrasonic sensors. Each type has its own advantages and disadvantages. Knowing these strengths and weaknesses is important. This information helps you choose the right sensor for your needs.

Delving into Float Level Sensors:

loat level sensors are one of the oldest and most common ways to measure liquid levels. These sensors have a float that moves up and down with the liquid level.

The float is connected to a switch or transmitter. When the liquid rises, the float goes up too. This action triggers the switch or sends a signal to show the level.

A key benefit of float level sensors is their simplicity and reliability. They are easy to install and need little maintenance, making them cost-effective for many uses. Also, their design allows them to work well in tough conditions and handle thick or corrosive liquids.

Float level sensors are not the best choice for every situation. They may not perform well in areas with moving fluids or vibrations.

These conditions can cause wrong readings or damage the float mechanism. Float sensors cannot accurately measure non-conductive or non-liquid substances. This limits where they can be used.

Understanding Ultrasonic Level Sensors:

Ultrasonic sensors use sound waves to measure how high liquids are. These devices send out sound pulses.

The pulses move through the air and hit the surface of the liquid. They then come back to the sensor. By measuring the time for the pulse to go and return, the sensor finds the distance. This helps it know the level of the liquid.

A key benefit of ultrasonic level sensors is that they measure without touching the liquid. This feature prevents contamination or interference. They can measure levels in both conductive and non-conductive liquids. This makes them useful for many applications.

Ultrasonic level sensors can have precision issues if there are blockages or foam on the liquid’s surface. Environmental factors like temperature changes, dust, or thick steam can also affect their performance. To get accurate level measurements, it is important to have the right installation conditions. You should also calibrate the sensor properly.

Advantages and Disadvantages of Various Level Sensors:

When we compare the three types of level sensors, we can summarize their pros and cons like this:

Float level sensors:

Advantages: Simple and reliable, cost-effective, great for tough conditions and thick liquids.

Disadvantages: It works less well with non-liquid or non-conductive materials. It is also affected by turbulence and vibrations.

Conductivity level sensors:

Advantages: Can adapt to different types of liquids. It can handle corrosive substances and high temperatures.

Disadvantages: It is less accurate with low-conductivity fluids. You need to think about the liquid’s conductivity range.

Ultrasonic level sensors:

Advantages: Measures without contact, works for both conductive and non-conductive liquids, and has many uses.

Disadvantages: It can get blocked by foam, dust, and steam. It is also affected by temperature changes. Accurate calibration is needed.

Conclusion: Selecting the Appropriate Level Sensor:

When picking the right level sensor for your needs, it is important to assess your specific requirements. Float sensors are reliable and cost-effective, but they may not work for every situation. Conductivity sensors offer flexibility, but they struggle with low-conductivity liquids. Ultrasonic sensors allow for non-contact measurement, but environmental conditions can affect their performance.

By understanding the pros and cons of each type of level sensor, you can make a smart choice. This will help you measure and manage liquid levels effectively in your field or application.

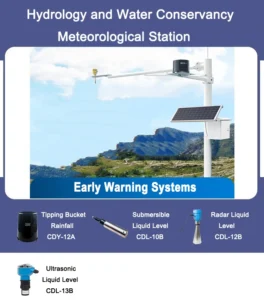

Hunan Coda Electronic Tech Co., Ltd works on corporate proposals to meet the needs of different businesses.

Their goal is to be the safest and most advanced sensor provider in the country. They are dedicated to excellence for both customers and employees.