What is a light sensing sensor? | how does light sensor work

How Do Light Sensors Work?

A light sensor is a device that can sense light. It turns light into an electrical signal. A light sensor can measure different properties of light.

These include how strong something is, its color, how often it happens, and where it goes. It works based on the Light-Electric effect.

These sensors use materials that react to converts light energy. This includes materials and parts for solar cells. They react to incoming light.

When amount of light hits these materials, their electrical properties change. This can lead to changes in resistance, the creation of current, or changes in voltage. The sensor translates these changes into an electrical signal output.

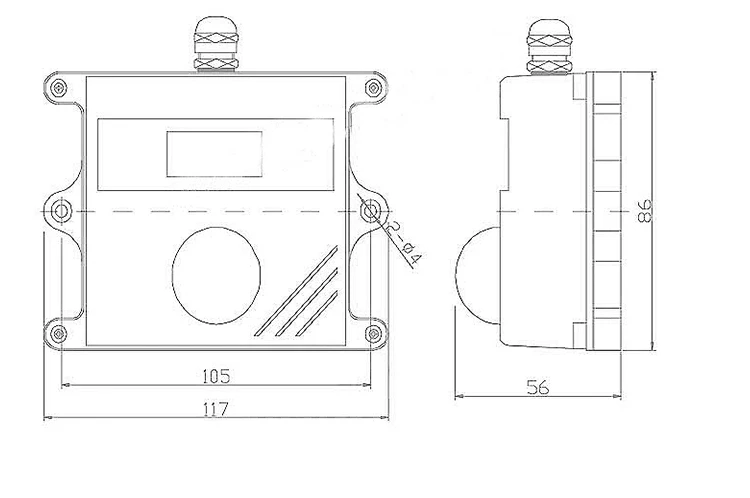

light sensor signal working principle

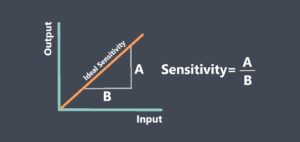

The raw electrical signal from the sensor is often weak, so it needs gain. A built-in amplifier in the sensor gives this gain. You can then process the stronger signal to get useful information. This includes how bright the light is and what color it is.

The processed data is given in a form that other electronic systems can read. The output can be an analog signal, which is smooth. It can also be a digital signal, which is made of separate parts.

Types of Light Sensors

The term “ambient light sensors” means many common types of light sensors. Each type has its own functions and uses. Here are four main types of light sensors:

1. **Light-Dependent Sensors**

Light-dependent sensors react to visible light, infrared, and UV light. When light hits them, their resistance changes based on how bright the light is.

A light dependent resistors is the simplest part of these sensors. It gives a weak electrical signal when it detects changes in light. After gain and processing through simple circuits, the sensor can, for instance, control automatic LED switching.

– **Applications:** These light sensor are often used in home devices. They help with things like adjusting TV brightness and automatic camera exposure.

**Advantages & Limitations:** They are cheap and easy to build. However, they have slower response times and less precise measurements than other types.

2. **Photo Diode Sensors**

A photo sensors works by using light that hits its PN junction. This light creates pairs of electrons and hole pairs.

These pairs make an electric current. The current depends on how bright the light is. You can use gain and circuits to measure light levels accurately.

– **Applications:** Photo diode sensors are used in industrial controls and automation lighting systems. They help find parts on assembly lines. They also recognize labels in packaging machines and help with robot positioning.

**Advantages & Limitations:** They respond faster and are more accurate than Light-Dependent sensors. However, they tend to cost more.

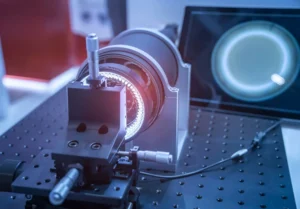

3. **Fiber-Optic Sensors**

Fiber-optic sensors send light through thin glass fibers. This light enters a modulator that changes its features. These features can be intensity, wavelength, or phase. The result is a light signal that gives specific values.

– **Applications:** These light sensors work well in digital data systems, like telecom networks and broadband internet. Companies also use them for automation tasks, such as positioning products, counting items, and identifying objects.

– **Advantages:** They provide strong insulation, are high sensitivity, and resist interference well. They also work well with computer systems.

4. **Light-Electric Effect Sensors**

The ambient light sensor changes light into signals. It does this with the photoelectric effect. The light-electric parts then turn these light signals into electrical signals.

These sensors can detect physical properties that light changes affect, such as intensity or temperature. They can also sense other non-electrical things that change with light. This includes the size of parts, how rough the surface is, and the shapes of objects.

**Measuring Range of Light Sensors**

**Outdoor Environments:**

– In direct summer sunlight, proportional to light intensity can range between 60,000 and 100,000 lux.

– Outdoors without direct sunlight, it typically ranges from 1,000 to 10,000 lux.

– On a night with a full moon, the brightness can drop to just 0.2 lux.

**Indoor Environments:**

– Bright summer rooms typically have light levels from 100 to 550 lux.

– Incandescent lamps produce about 12.56 lux for each watt. This amount can change based on the bulb size. Smaller bulbs give off more lumens than larger ones.

– Fluorescent lamps use 3 to 4 times less energy than incandescent bulbs. They give off the same amount of light.

**Optimal Installation for Light Sensors**

To make sure they work well, ambient light sensors need to be installed correctly. Here are some best practices:

Installation Location**

– Place the light sensor in the center of the area you want to measure illuminance.

– Pick a spot that is free from reflective or scattering objects nearby.

– Keep the area clear. This helps avoid mistakes in measurement. Stay away from artificial light sources like lamps, doorways, and windows.

Installation Height**

In indoor spaces, the standard height is between 2.5 and 3 meters. If you need a larger detection range, change the height as needed. For outdoor light sensors, place them at a height of 2.5 to 4 meters. This will help make sure nearby objects do not block them.

Avoiding Strong Light Interference**

To keep data readings accurate:

– Put the sensor away from bright lights or direct sunlight. This means not using incandescent lights, LED lamps, or solar reflectors.

Installation Angle**

Make sure the sensor is installed straight up and down. Do not tilt the sensor when you install it. This helps reduce measurement errors.

Applications of Light Sensors**

Light sensors help detect and measure how much light there is. They change these readings into electrical signals.

These sensors are helpful in many fields. They help with automatic control. They change the lights and look around. Here are some of the main ways they are used:

1. Automatic Lighting Control**

– Light sensors can turn on indoor lights. They can also change the brightness at night or when it’s cloudy.

– During sunny times, they save energy by dimming or turning off lights that are not needed.

– They help change stage lights during shows. They adjust the color and direction using set cues.

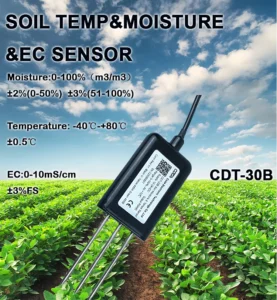

– In smart homes, they work with other sensors, like temperature and humidity sensors, for a smart living space.

2. Weather Monitoring**

– Light sensors play an important role in weather stations. They track light conditions in remote areas. This includes sunny, cloudy, and foggy weather.

3. Temperature Control Systems**

– Light sensors help improve comfort and save energy. They change curtains, blinds, or HVAC systems to do this. They change these based on the light levels inside and outside.

4. Agricultural Production**

They are important for running greenhouses. They help crops get enough light by managing sunshades or lights. This leads to better yields.

5. Industrial Automation**

Light sensors help make manufacturing more accurate. They check the brightness and see small changes in color. For example:

– Automated robots use light sensors to find their exact position.

– Smart warehouses use them to check safety in delivery vehicles.

6. Security Systems**

In security operations, like fire alarms or intrusion detection systems, light sensors detect changes in light. They help find strange activities and send alerts. Light sensors offer efficient solutions in many industries. They help with better automation, save energy, and make life better.