What are Humidity Sensors and Their Uses?

Humidity sensors are tools that measure how much moisture or water vapor is in the air. These flexible tools are used in many areas. They help with checking the environment and with industrial tasks.

Humidity sensors are important in many fields. They help protect important electronics. They also predict the weather and make people feel more comfortable.

Many different places use humidity sensors to work well. These include space stations, smartphones, data centers, art galleries, weather stations, and jet engines. Their technology has changed a lot over the years.

They began with early analog models that were not very precise. Now, they use modern digital sensors. These sensors are very accurate.

They have a level of ±3% RH (Relative Humidity). This leap in advancement is largely due to electronic precision and sophisticated design techniques.

Modern humidity sensors often use capacitive, resistive, or thermal methods. Each of these methods has its own benefits based on how they are used. For example, thermal techniques can measure absolute humidity.

These sensors are essential for keeping the best environments in many places. These include farms, heating and cooling systems, medical uses, weather centers, and food processing businesses.

This guide looks at the basics of humidity sensors. It looks at the different types, how they function, and their real-world uses. Let’s start by looking at how they work and where they are used.

**What Is a Humidity Sensor?**

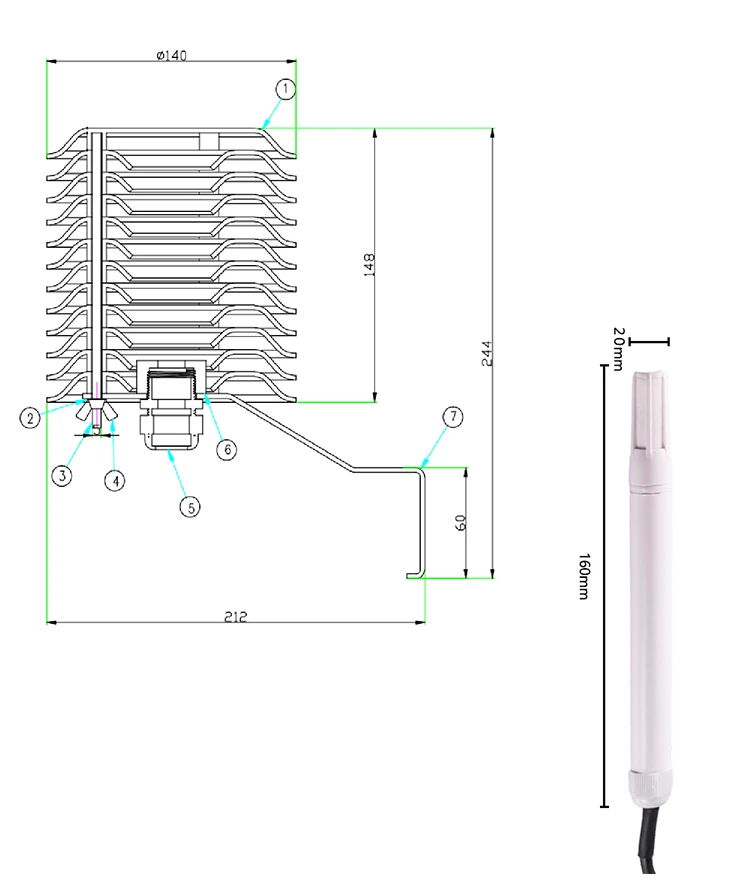

A humidity sensor checks how much moisture is in the air. It uses special methods to do this. These devices come in different sizes and designs based on how they are meant to be used.

Some models are very small. They are only 1.3 mm long, 0.7 mm wide, and 0.5 mm thick. This size makes them great for microelectronics, and they still work well.

Types of Humidity Sensors

Humidity sensors are different because of how they work and how they sense humidity. Here are the three main types:

**1. Capacitive Humidity Sensors**

These sensors work like a sandwich. They have a special material inside that soaks up moisture from the air. Two conductive plates cover this material from the top and bottom.

As the material takes in water, its capacitance changes. This allows the sensor to measure humidity levels correctly. Capacitive sensors are commonly used due to their reliability and cost-effectiveness.

**2. Resistive Humidity Sensors**

These sensors use materials that change their electrical resistance when humidity levels change. This change in resistance is linked to the moisture in the air. Manufacturers carefully adjust these sensors in controlled settings. This makes sure they are correct.

**3. Thermal Humidity Sensors**

Thermal sensors have two parts. One part is exposed to dry air, and the other is exposed to moist air. The warm, humid air heats up.

We can see how fast it cools down. If it cools quickly, it has more moisture. Unlike capacitive or resistive systems, thermal sensors measure absolute humidity rather than relative humidity.

How Do Humidity Sensors Differ from Other Environmental Sensors?

Environmental sensors can measure things like temperature, pressure, wind speed, and how bright the light is. Humidity sensors only measure moisture in the air. They use materials that are sensitive to water vapor, such as hygroscopic salts, polymers, and metal oxides.

How Humidity Sensors Work

Humidity sensors use materials that can absorb or react to moisture in the air. These materials include salts that soak up moisture, special plastics, and metal compounds. Each has unique properties that make them good for different types of humidity measurement.

**Hygroscopic Salts**

Compounds like lithium chloride or sodium chloride absorb water through their chemical structure to provide measurable humidity values. Earlier designs often used salts that soak up moisture for sensors. However, these sensors usually last from six months to a few years.

**Polymers**

For applications that require more durability and stability against air pollutants, polymer-based sensors are a better option. These devices provide quick response times and accurate readings from 0 to 100% relative humidity. They can last between five and ten years without needing to be recalibrated.

**Metal Oxides**

Metal oxide layers, like Al₂O₃, TiO₂, and ZnO, are often used in capacitive sensors. They perform well in high heat and resist chemicals. Their strong design lets them work well for up to fifteen years.

Key Components of Humidity Sensors

A typical capacitive humidity sensor has several layers. It includes an upper electrode and a thin-film polymer layer for moisture absorption.

There is a lower electrode and a glass base that keeps the structure stable. Resistive sensors use materials that take in moisture. These materials change their electrical resistance when humidity levels rise.

Humidity sensors measure how much moisture is in the air. They are important in many industries and uses. These sensors provide information about relative and absolute humidity levels.

This information helps us understand the weather. It helps improve environmental control systems and various processes.

Understanding What Humidity Sensors Detect

Humidity sensors can detect two main types of moisture levels: relative humidity (RH) and absolute humidity (AH). The difference between these types is important for understanding atmospheric data well.

Relative Humidity vs. Absolute Humidity

Air can hold a certain amount of water vapor, and this amount depends on the temperature. Warmer air can hold more moisture than cooler air.

– **Relative Humidity**:

This shows how much moisture is in the air. It is expressed as a percentage. This percentage is compared to the most moisture the air can hold at a certain temperature.

For example, 100% relative humidity (RH) means the air is full of water. In contrast, 50% RH shows it has half the water it can hold at that temperature.

– **Absolute Humidity**:

Absolute humidity measures the total water vapor in one cubic meter of air. This is not the same as relative humidity. It is usually shown in grams per cubic meter (g/m³). It does not change with temperature, so it is a fixed amount.

The Importance of Dew Point

The dew point is an important measure. Humidity sensors help to find it. It is used in weather forecasting, farming, HVAC systems, and aviation. It shows the temperature when the air has a lot of moisture. This leads to condensation.

For example, if the air temperature is 30°C and the dew point is 21°C, surfaces at or below 21°C will collect moisture—similar to condensation on a cold glass. Monitoring the dew point helps predict conditions like dew, fog, and frost.

How Humidity Sensors Work

Humidity sensors measure how much moisture is in the air. They do this by turning physical properties into data. This includes things like electrical signals or currents.

– **Electrical Properties and Measurement Techniques**

– **Resistive Sensors**: Hygroscopic materials in these sensors change their electrical resistance when they come into contact with moisture. This change is turned into an analog voltage signal, like 0-5V or 0-10V.

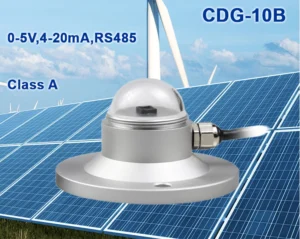

– **Capacitive Sensors**: The capacitance changes when moisture is absorbed from the air. This change is measured and sent out as an analog signal. It is usually 0-5V, 0-10V, or 4-20mA.

– **Signal Processing and Data Interpretation**

Raw electrical signals from humidity sensors often need more processing. This helps make a digital version using microcontrollers. These processed outputs utilize communication protocols such as RS485 (MODBUS), I2C, or SDI-12.

Digital signals help us track, save, and combine data in control systems. This is helpful for HVAC systems. HVAC stands for heating, ventilation, and air conditioning. It also applies to other humidity management systems.

Factors Impacting Measurement Accuracy

The accuracy of a humidity sensor can be affected by its design and outside conditions. Problems like pollution or poor installation can cause errors in readings. Regular calibration following the manufacturer’s guidelines is critical for reliable performance. Also, old parts may need maintenance or replacement to keep working well.

Applications and Uses of Humidity Sensors

● **Agriculture and Greenhouse Management**

Humidity sensors play a key role in climate control systems. They help plants grow well in greenhouses and on farms. These devices measure humidity in the soil and air. This helps farmers adjust water and ventilation systems to improve crop yields.

● **HVAC Systems and Building Automation**

In HVAC systems, humidity sensors help keep the environment comfortable for people inside. To control humidity for people or animals, it is important to keep conditions comfortable.

This usually means a temperature between 22°C and 27°C. The humidity level should be between 40% and 60%. Sensors give information that helps HVAC systems control moisture levels.

● **Medical and Pharmaceutical Storage**

Keeping track of humidity is important in medical settings. This is especially true for keeping and handling drugs. Improper humidity levels can harm the quality of drugs. This can make them not work well or even cause harm.

Keeping controlled environments during drug manufacturing helps ensure product quality and consistency.

● **Meteorology and Weather Forecasting**

Humidity sensors play a key role in weather science. They help make accurate weather predictions. Remote weather stations use sensors to study changes in fog, rain, dew points, and other weather conditions. This helps provide better forecasts and insights into environmental events.

● **Electronics Manufacturing and Data Centers**

High humidity can cause big problems in electronics. It can lead to corrosion, short circuits, and parts not working right because of more oxidation. Keeping the right humidity level helps avoid problems. This ensures that electronic devices and data centers last longer and work well.

● **Food Processing and Storage**

Humidity management is key to maintaining food quality and preventing spoilage. Different types of food need different humidity levels. For example, leafy greens do well in high humidity to stay fresh. On the other hand, dry goods like grains need low humidity to stop mold from growing.

**Conclusion**

Humidity sensors are becoming very important in industry and farming. They can measure the moisture in the air accurately.

They come in different types: capacitive, resistive, and thermal. Each type is good for certain needs. Keeping the right humidity levels is important.

These sensors help improve product quality. They also support sustainability and productivity. This benefits people, machines, wildlife, and crops.

Modern humidity sensors are now very small. They are about the size of a grain of salt. They are more accurate, last longer, and work well with Internet of Things systems. This change has helped many industries update quickly.

Coda Sensors provides smart solutions for people who care about accuracy and strength. Their products have a humidity accuracy of plus or minus 3% RH. They have a temperature accuracy of plus or minus 0.5°C. Their pressure accuracy is plus or minus 1 hPa.

Their sensors work well for weather, farming, and industry. They provide strong outputs like 4-20mA, 0-5V, 0-10V, and RS485 MODBUS.

Coda Sensors are made for long-term use, lasting 5 to 10 years. They provide reliable performance. Check out our website for a wide range of options made just for you.

**Commonly Asked Questions (FAQs)**

1. **Is 70% Humidity Regarded as Elevated?**

For indoor environments, an ideal range is 40% to 60% RH. While 70% humidity can be good for some plants and food storage in greenhouses, it is often too high for people. This level can cause condensation to form on surfaces. It can also make people feel uneasy.

2. **How Often Should Users Calibrate a Humidity Sensor?**

Calibration needs differ for each type of sensor. Capacitive sensors usually need to be calibrated once a year. Resistive sensors need checks every six to twelve months.

Thermal conductivity sensors should be calibrated once a year. Always check the manufacturer’s guidelines for the correct calibration times for each sensor type.

3. **Can Humidity Sensors Work in Extreme Temperatures?**

Yes, some humidity sensors work well in extreme conditions. Some can work at temperatures as high as 200°C. Capacitive sensors use special polymer materials that soak up moisture.

They work well in a wide range of temperatures. These sensors give precise measurements and control.