what is water sensor | tank water sensor

A water level sensor is a device that finds and measures how high the water is. It works in places like tanks, ponds, rivers, and other types of water. The way a water level sensor works can differ based on its type. Here are a few common methods:

1. Mechanical Water Level Sensors:

– Float Switches: These devices work with a float that goes up and down based on the water level. As the water level goes up, the float rises. This turns on a switch or sends a signal.

– Piston or Tube Type: In a sealed tube, a piston or float moves up and down based on the water level. The water level is linked to where the piston is located. Someone usually sends this information to a gauge or a controller.

2. Capacitive Water Level Sensors:

– These sensors measure the dielectric constant of water. This constant changes with the water level. The plates of a capacitor are partly in water.

As the water level changes, the capacitance changes too. The system tracks changes in capacitance. It then turns this data into a measurement of the water level.

3. Ultrasonic Water Level Sensors:

– Ultrasonic sensors send out sound waves that are very high in frequency. These waves move through water to get to a receiver. The system measures how long it takes for sound waves to go to the bottom of the tank and come back.

We can find out how deep the tank is by knowing the speed of sound in water. This helps us know the water level.

Ultrasonic level sensors work by sending out ultrasonic pulses. They measure how long it takes for these pulses to bounce back. This information helps us find out how high the liquid level is. They usually provide accurate measurements and can work with different types of liquids.

Application Scenarios for Ultrasonic Water Level Sensors:

Water treatment sector: used to check water levels in tanks, towers, or troughs. This helps ensure the water supply system works well.

Chemical plants check the liquid levels in storage tanks or reactors. This helps control how things are made.

Food processing facilities check the amounts of food ingredients and finished products in containers. They make sure that production is safe and of good quality.

4. Hydrostatic Water Level Sensors:

These tank water sensor work based on hydrostatic pressure. A pressure sensor goes underwater. As the water level goes up, the pressure goes up too.

We change this pressure measurement into a water level reading. It takes into account the specific gravity of water and the sensor’s depth.

Product Description: These sensors measure how high a liquid is by checking the pressure of gas or liquid above it. They work well with different liquids and can handle tough situations.

Application Scenarios for Pressure-Type Liquid Level Sensors:

Oilfield Sector: This is used to check levels in tanks for oil, water, or chemicals. This helps manage how oil wells work.

Clean Water Treatment: This is used to check levels in various tanks and troughs at wastewater treatment plants. This helps ensure the treatment process works well.

Pharmaceutical Industry: In drug manufacturing, these sensors check levels in reactors or storage tanks. This ensures quality and follows the rules.

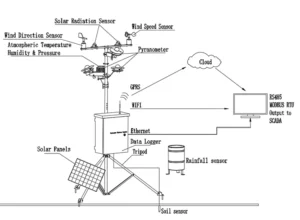

6. Wireless Water Level Sensors:

– These devices often use a float switch or a different sensor. They send water level data wirelessly to a remote station or controller.

When picking a water level sensor, you should think about a few important factors. First, think about the accuracy you need. Next, think about the type of waterbody.

Also, check the water’s depth. Check for any chemicals or solids that might impact the sensor. Think about the environment where you will put the sensor.