Using electrochemical sensors in gas detection.

The use of electrochemical sensors for gas detection has grown a lot with new science and technology. Gas sensors are being made smaller and smarter. This is happening because of new technologies, such as the Internet of Things. They are also being made to work together and in various ways.

Electrochemical sensors are now widely used to detect gases. They have a straight output, use less power, and provide better resolution.

They give more accurate and steady measurements than other kinds of sensors. After years of new technology, these sensors can now detect specific gases very well. This makes them essential for gas detection.

At first, electrochemical sensors were made to check oxygen levels. As technology got better, they learned to find different toxic gases, even at low explosive levels. These sensors show great sensitivity and selectivity when they work.

This reliability has made them a popular choice for checking gas levels. Today, people use their apps in many places, both at home and on the go. They play an important role in monitoring different gases. Here is a brief overview of the basics of electrochemical gas sensors:

1. **Principles of Electrochemical Sensors**

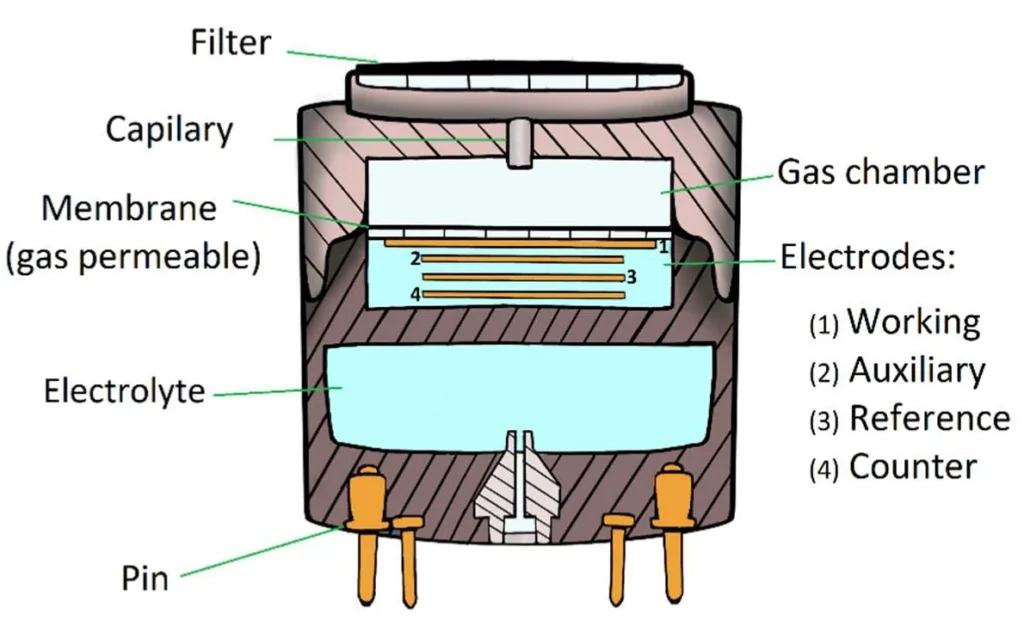

Most gas sensors work by diffusion. In this mode, gas samples enter the sensor through a small inlet on its surface. In some cases, a suction pump pulls air or gas samples into the sensor.

To stop water or oil from coming in, a breathable membrane is put at the air inlet. You can change the size of the air inlet during the design phase. This change affects how sensitive the sensor is and how far it can measure.

A bigger air inlet makes sensitivity and resolution better. A smaller air inlet lowers them but allows you to measure a wider range.

2. **Components of an Electrochemical Sensor**

– **Breathable Membrane (also known as a Hydrophobic Membrane)**

This membrane covers the sensing electrode. It sometimes controls how much gas gets to the surface of the electrode. This type of sensor is called a coated sensor. It is usually made from Teflon films that have a few holes.

You can use Teflon films that are very porous and have capillary adjustments. This lets us control how gas molecules can enter. Sensors that use this method are called capillary sensors.

The membrane not only provides mechanical protection but also filters out unwanted particles. To achieve good gas transfer, it is important to choose the right pore size. The pore size should let enough gas molecules reach the sensing electrode. At the same time, it should prevent liquid electrolyte leaks and quick drying.

– **Electrode**

Choosing the right electrode material is important. It helps keep the catalytic activity steady in the electrochemical reaction. Precious metals such as platinum and gold are often used.

They react well with gas molecules after catalysis. You might need up to three electrodes. This depends on the design of the sensor. These electrodes are made from various materials to help with the reactions.

– **Electrolyte**

The electrolyte helps with reactions and allows ions to move easily to the electrodes. It must stabilize the reference potential with the reference electrode. It should also work well with all types of sensor materials. If the electrolyte evaporates too fast, the sensor works less well because the signals weaken.

– **Filter**

Sometimes, filters are put in front of the sensor to get rid of unwanted gases. Activated carbon is often used because it can filter out many chemicals. However, it cannot capture carbon monoxide. Choosing the right filter helps the sensor find its target gas better.

3. **Operation of an Electrochemical Sensor**

Electrochemical sensors create an electrical signal to work. This signal shows how much of the target gas is there. It occurs through chemical reactions with the gas that is being sensed.

Hunan Coda Electronic Tech Co., Ltd is a top maker of sensor solutions. They are known for making some of the best products in the industry.

Hunan Coda Electronic Tech Co., Ltd is a top performer. They concentrate on great operations. Their goal is to make customers happy. They also aim for strong financial results.

Conclusion

In summary, it is the best option for systems that watch the environment. Not seeing its value might cost you more than you realize. Don’t wait too long. Get it now before the chance is gone.