Tilt Sensor Functionality, Types, and Applications

**What is an Inclinometer?**

An inclinometer, also known as a tilt sensor, measures the angle of tilt. It can also find changes in still structures. These sensors are important tools in areas like bridge building, railway work, civil engineering, and safety checks for buildings.

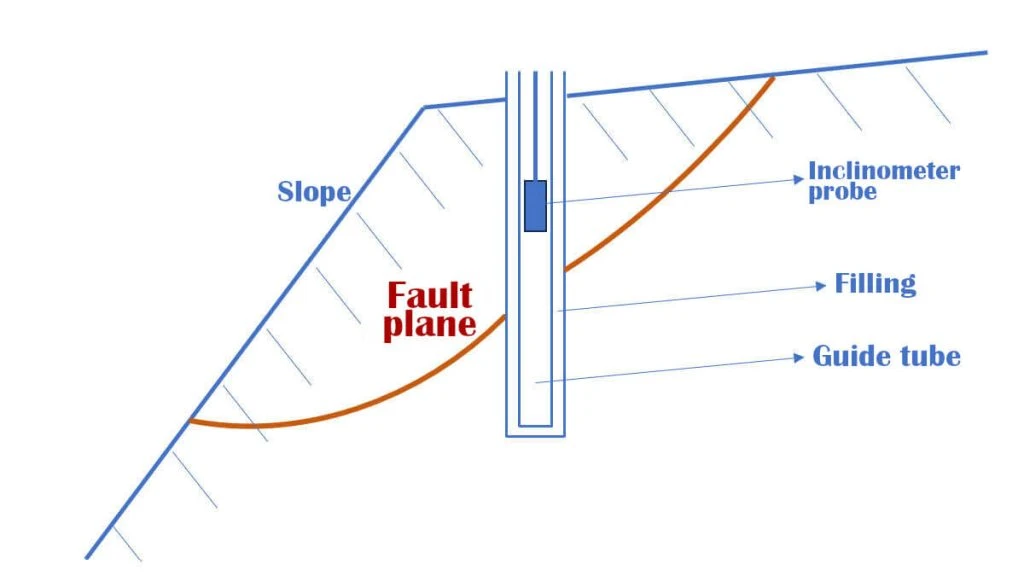

The installation process for inclinometers depends on what they are used for. For example, vertical installation is good for checking slope stability. It helps track movement in retaining walls and embankments.

Horizontal installation is better for tasks like leveling foundation trenches or farmland. It also helps to check how flat the surface is.

**How Does an Inclinometer Work?**

Tilt detector work by measuring how fast something is speeding up or slowing down. You cannot directly measure velocity in a system.

You can measure acceleration. This allows you to find linear velocity through integration. You can also find linear displacement from this.

Tilt detectors work like acceleration meters. They use the principle of inertia. When still, these sensors only detect gravitational acceleration.

This is because there is no side or up-and-down movement. The angle between the sensor’s sensitive axis and the vertical axis shows how much it is tilted.

**Types of Tilt Tilt Detectors**

Tilt detectors come in different types. Each type needs a specific mix of parts and sensors to gather data well. Their classification is based on how they are built and how they work.

**1. Single-Axis Tilt Sensor**

A single-axis tiltdetectors is made to detect changes in angle along one axis. It works according to Newton’s Second Law. It uses inertia to measure how fast an object speeds up.

**Applications:**

– Good for measuring angles in one plane or direction.

**2. Dual-Axis Tilt detectors**

Dual-axis tilt detectors can detect changes in angle on both the X-axis and Y-axis. These sensors follow simple motion rules. They use math to track movement correctly.

They have two sensors set up at a 90-degree angle. Each sensor gives outputs based on its tilt to the vertical axis.

**Applications:**

– Offers better measurements for tasks that need multi-dimensional angle data, like roll and pitch calculations.

**Differences Between Single-Axis and Dual-Axis Tilt detectors:**

– **Measurement Capability:** Single-axis tilt detectors can only measure roll or pitch angles. This depends on how they are installed. In contrast, dual-axis sensors can measure both roll and pitch angles at the same time.

– **Functional Design:** The active sensing area for dual-axis sensors can be a point or a line on a sloped surface. Single-axis sensors can only provide linear readings.

– **Application Examples:** To check vertical wall angles, use single-axis sensors. They use the wall and its foundation as a guide. For situations like slowly turning a vertical rod, you need dual-axis sensors. These sensors can track point contacts well.

**Types of Tilt Sensors Based on Working Principle**

1. **Solid Pendulum Tilt Sensor**

Solid pendulum tilt detectors use a balanced servo system that responds to force. This mechanism has parts such as a pendulum, a cycloid, and a bracket. The pendulum feels the force of gravity **G** and a pulling force **T**.

This creates an external force **F = Gsinθ = mgsinθ**. In this context, **θ** represents the angle formed between the pendulum’s cycloid and the vertical. For small angles, **F** and **θ** have a straight-line relationship. This relationship is the basis for strain-type tilt detectors.

*Schematic of Solid Pendulum Tilt detector*

2. **Liquid Pendulum Tilt detectors**

Liquid pendulum sensors use a conductive liquid inside a glass shell. This shell has three platinum electrodes attached on the outside. The electrodes are placed next to each other and spaced evenly.

When the sensor is flat, the electrodes are fully covered by the liquid. When an alternating voltage is applied to two electrodes, ionic currents flow between them. This creates resistances **RI** and **RIII** in the liquid.

If the device stays flat, **RI = RIII**. But tilting changes the liquid levels near the electrodes. As the depth of immersion changes, the middle electrode stays nearly the same, while the side electrodes change.

For example, if the left electrode goes down, the number of conductive ions decreases. This increases resistance (**RI > RIII**). If you tilt the other way, this relationship flips (**RI < RIII**).

*Schematic of Liquid Pendulum Tilt Sensor*

3. **Gas Pendulum Tilt detector**

The gas pendulum tilt detectors works with a closed cavity that holds gas and a hot wire. When it tilts or moves, the heating wire changes how much it resists. These changes are about the tilt angle (**θ**) or acceleration, like how a pendulum moves.

The mechanism uses thermal energy transfer in a sealed space. The hot wire is the only heat source that warms the gas inside. Heat convection is the main way energy moves between gas and wire.

*Schematic of Gas Pendulum Tilt detector*

**Comparison of Solid, Liquid, and Gas Pendulum Sensors**

Each type of tilt detector has its own benefits.

– **Sensitive Mass:**

– Solid pendulums depend on the mass of the pendulum.

– Liquid pendulums use electrolytes as their active mass.

– Gas pendulums depend on gas movement in sealed cavities.

– **Anti-Vibration/Impact Properties:**

Gas pendulums work well in places with strong vibrations or heavy loads. This is because they have a light mass and low inertial force when they hit something. However, they need complicated motion control and are not as precise as other types.

– **Accuracy and Applications:**

Solid pendulum sensors offer a wide range of measurements and high accuracy. This makes them good for many uses, like acceleration sensors. Liquid pendulums provide both stability and precision. They are used in many high-accuracy systems.

Applications of inclinometers:

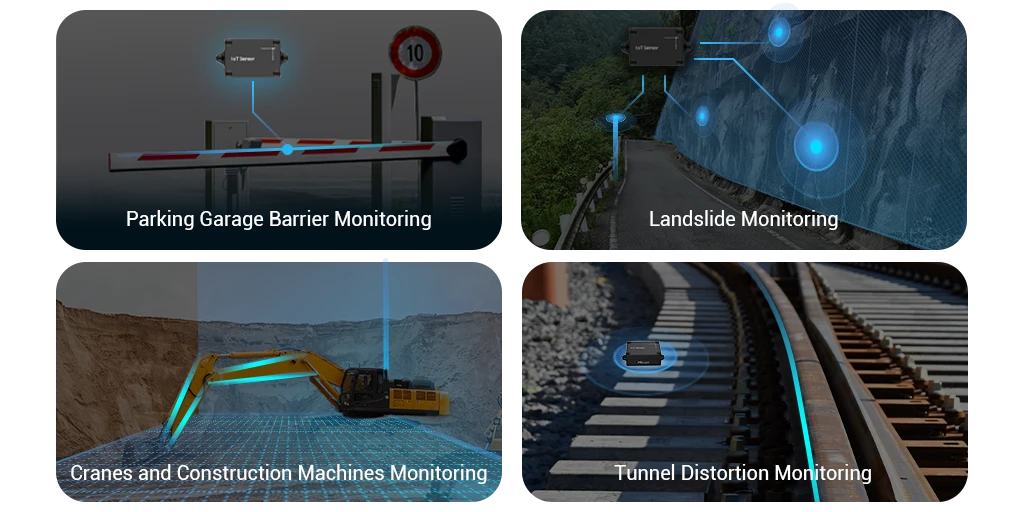

1. Inclinometers are used in machines that level foundation trenches and farmland. They check and control flatness to make sure leveling is accurate.

2. In paddy fields, graders use inclinometers to level the soil. This technology greatly lowers the amount of water used for irrigation. It also improves how well fertilizer works in rice production.

3. Vehicle-mounted photoelectric tracking devices use inclinometers. They put dual-axis inclination sensors at the base. These sensors check how level the base is. This ensures the on-board tracking equipment works with high precision.

4. Urban pipeline robots use inclinometers to check their angle while they work.

5. An inclinometer plays a vital role in ship-launching procedures, aiding in accurate positioning and measurements.

6. On a ship-borne water platform, inclinometers are placed at the base of satellite tracking antennas. They help keep the antennas level.

These devices control the platform in real-time. They separate the pitch and roll movements of the hull. This ensures stability and accurate operation.

7. Large ships use inclinometers to check and adjust the swing of hooks when loading and unloading.

8. Inclinometers are used in many industries for measuring angles. They help keep track of unsafe buildings and protect important historical sites. They also assess bridge angles, watch tunnels, check dam stability, and control drilling angles.

Installation process for inclinometers:

To install an inclinometer correctly, you must use certain techniques. Most inclination sensors have a built-in zero-adjustment feature. This lets users set the sensor to “zero” at a certain angle before taking measurements.

Before installation, find the right location. Then, decide the angle or plane that needs measuring. This is crucial for aligning the inclinometer with reference points relative to the chosen plane.

During installation, attach the sensor firmly to the target surface. Then, use the zero-adjustment function to reset the baseline readings.

This step helps get accurate angle readings. It lowers the chance of mistakes when measuring. This ensures reliable and steady performance.