Assessing Float, Conductivity, and Ultrasonic Level Sensors: Advantages and Disadvantages

Overview of Level Sensors:

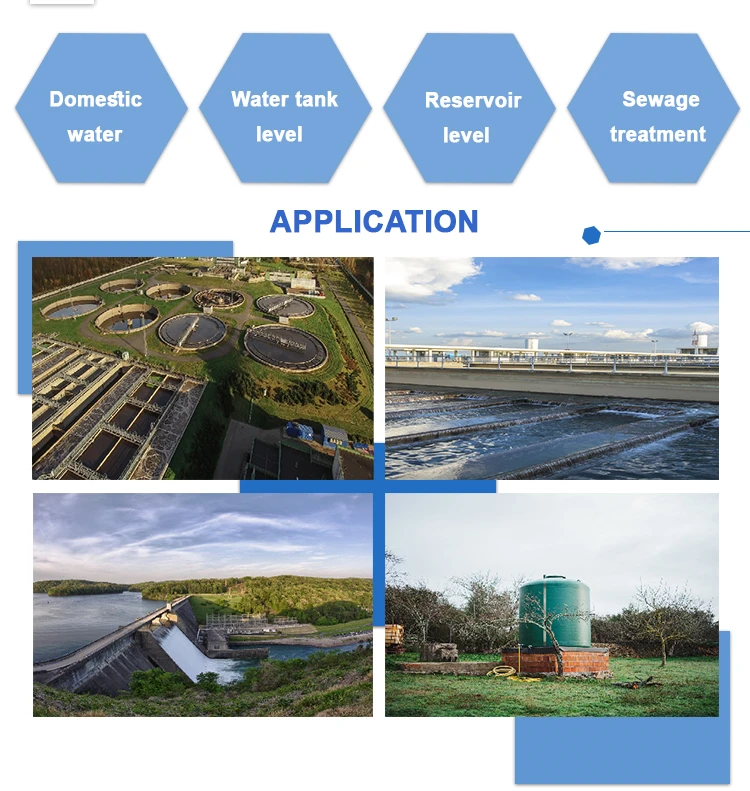

In industries like water treatment, manufacturing, and oil and gas, it is important to monitor liquid levels. This helps with efficiency and safety. Level sensors are useful tools. They provide reliable ways to measure and control liquid levels.

This discussion looks at three common types of sensors: float sensors, conductivity sensors, and ultrasonic sensors. Each choice has its own strengths and weaknesses. It is important to know these things before picking one for specific uses.

Exploring Float Level Sensors:

Float level sensors are a common way to measure liquid levels. They have a float that can stay on the surface of a liquid. This float is linked to a switch or transmitter.

When the liquid level goes up or down, the float moves. This movement turns on the switch or sends signals to show the current level.

One big benefit of float sensors is that they are easy to use and dependable. They are simple to set up, need little care, and are low-cost. This makes them great for many uses.

Their design helps them handle tough environments. They can also handle thick liquids and strong chemicals.

Float sensors have advantages, but they also have some drawbacks. They can have problems in places with rough fluids or strong vibrations.

This can lead to wrong readings or damage to parts. These sensors are not made for non-liquid or non-conductive materials. This limits where they can be used.

Analyzing Conductivity Level Sensors:

Conductivity sensors check how well a liquid can conduct electricity. They use this information to find liquid levels. A probe or electrode is placed in the substance.

Conductive liquids allow current to flow easily. Non-conductive liquids make it harder for current to flow. This difference helps us see the level.

The versatility of conductivity sensors is a clear strength. They can check various kinds of liquids. This includes harmful chemicals, water-based solutions, and other items.

They also work well in high temperatures. They are less likely to fail than float-based options.

However, conductivity sensors have their own challenges. Monitoring fluids with very low conductivity, like some oils or deionized water, can cause unreliable measurements. It is important to check the conductivity of the liquid before choosing these sensors.

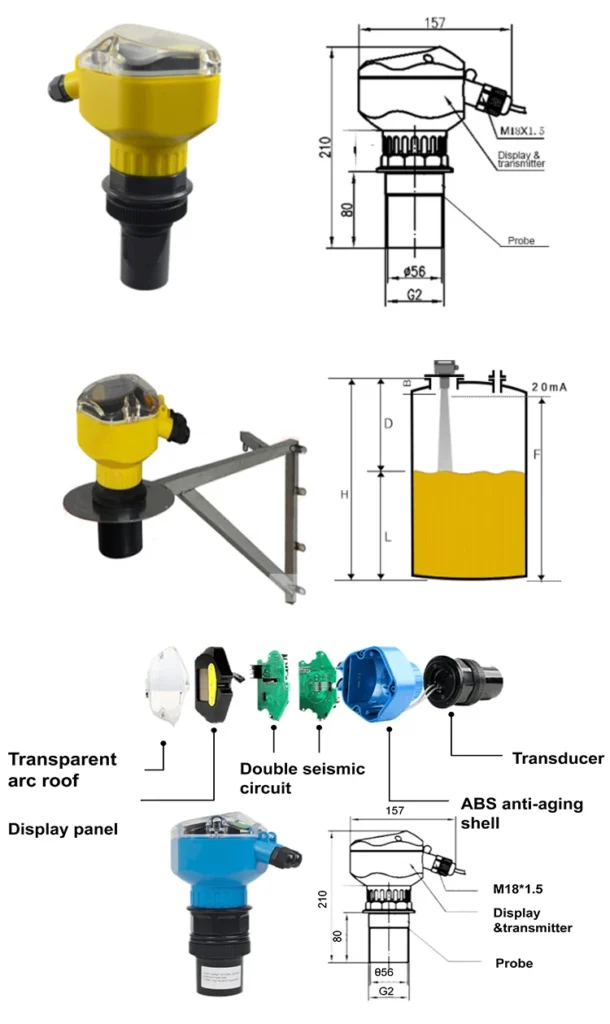

Understanding Ultrasonic Level Sensors:

Ultrasonic level sensors use sound waves to check how high liquids are. They do this without touching the liquid. They send out sound pulses.

These pulses bounce off the liquid surface and come back to the sensor. The sensor finds the liquid level by measuring how long the wave takes to travel.

One main benefit of ultrasonic sensors is that they can measure without making contact. They stay away from touching the liquid. This lowers the chance of contamination and helps keep things calm.

They work well with both types of liquids: conductive and non-conductive. This makes them helpful for many different uses.

Ultrasonic sensors have strengths, but they are affected by outside factors. Obstructions, foam on the liquid surface, temperature changes, steam, or dust can affect their accuracy. Proper installation and calibration are important. They help solve these problems and lead to trustworthy results.

Pros and Cons of Different Level Sensors:

A comparison of float, conductivity, and ultrasonic level sensors shows these important points:

Float level sensors:

– Advantages: The design is simple and works well. It is also affordable. It can handle tough conditions and thick liquids.

– Disadvantages: It has limited use with materials that are not liquids or not conductive. It is also sensitive to turbulence or vibrations.

Conductivity level sensors:

– Advantages: It is very flexible. It works well with harmful materials and in hot settings.

– Disadvantages: Low-conductivity fluids can lead to problems with accuracy. It is important to first check the conductivity range of a liquid.

Ultrasonic level sensors:

– Advantages: Measures without touching the liquid. It works with both types of liquids: conductive and non-conductive. This makes it good for many uses.

– Disadvantages: Foam can be blocked by obstructions and buildup. It is also influenced by changes in the environment, such as temperature, dust, and steam. This means it needs careful changes.

Selecting the Right Level Sensor:

To pick the best level sensor, you should think about your needs and any limits of your application. Float sensors are a reliable and affordable choice, but they may not meet all operational needs.

Conductivity sensors are flexible, but they can have trouble with fluids that have low conductivity. Ultrasonic sensors are precise and do not touch objects. However, they can have problems because of their surroundings.

By looking closely at the pros and cons of each sensor type, you can make a smart choice. This choice will help you watch and manage liquid levels well for your industry or use.

Hunan Coda Electronic Tech Co., Ltd. provides custom solutions for businesses around the world.

The company aims to be the safest and most innovative sensor provider in the country. It is committed to excellence for both customers and employees.

Many customers trust Hunan Coda Electronic Tech Co., Ltd. for reliable sensor solutions and advanced technology.