How to Measure oil measurement Level

Measuring the oil level correctly is important in many areas. This includes keeping car engine oil in good shape and checking storage tanks in industries. Different situations require different methods.

Each method has its own rules, benefits, and drawbacks. Here’s a closer look at the common techniques used to measure oil levels.

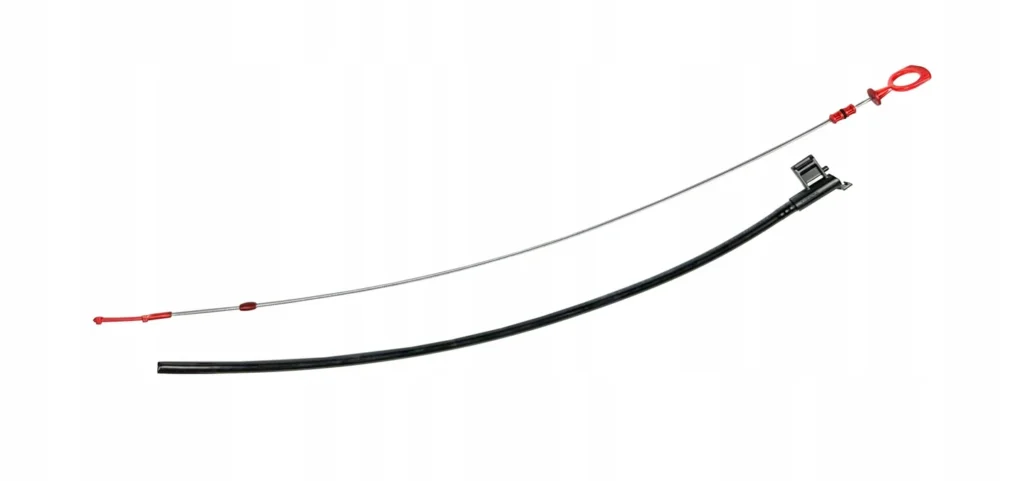

Manual Dipstick Method

Principle and Operation

The dipstick is a common tool for checking oil levels, especially in car engines. It is a long, thin rod with markings. To check the oil level, first turn off the engine. Then, remove the dipstick from its tube.

After you clean the dipstick with a cloth or paper towel, put it back in the tube. Then, pull it out again. The oil will cover the lower part of the dipstick.

You can check the level with the markings. A dipstick has a “low” mark and a “full” mark. The oil level should be between these two marks.

Advantages

This method is easy and cheap. It does not need extra power. It gives vehicle owners a simple way to check the oil level often.

This helps them spot any big drops that might mean a leak or too much oil use. Also, it doesn’t need special training. Most people with basic mechanical skills can use a dipstick well.

Limitations

The dipstick method is a bit subjective. How a user reads the markings can change how they see the oil level.

It can also be messy, as oil might drip during the process. It is only suitable for small-scale uses, like car engines. and may not work well for large storage tanks or industrial settings that need frequent and automated measurements.

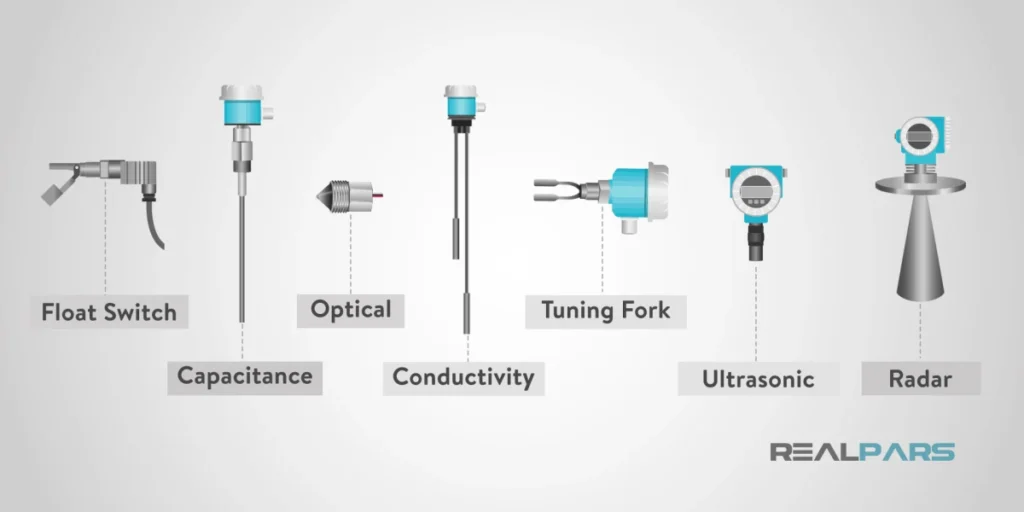

Float – Based Level Sensors

Principle and Operation

Float-based sensors use buoyancy to work. A hollow, buoyant float is placed in the oil. It floats on the surface of the liquid. When the oil level changes, the float moves up or down. This movement of the float gives a measurement.

This can be done in a few ways. A rod connected to the float can move inside a tube. We can find the rod’s position using mechanical or electrical methods. Sometimes, a cable or chain connects to the float. The cable goes around a spool. We measure how the spool turns to check the oil level.

Advantages

Float-based sensors are simple and reliable for measuring oil levels in tanks of different sizes. They offer continuous level monitoring and work well for both above-ground and underground storage tanks.

They are also cheaper than some advanced electronic sensors. it can work without an external power source in mechanical systems.

Limitations

These sensors can be influenced by things like oil thickness and foam or sludge in the tank. Thick oils can slow down the float’s movement, causing wrong readings. If debris or foam collects on the float, it can affect how well it floats.

This can cause wrong level measurements. Technicians must also do maintenance to keep the float and its parts working well.

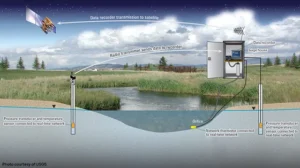

Ultrasonic Level Sensors

Principle and Operation

Ultrasonic level sensors use high-frequency sound waves. They measure how far the sensor is from the oil surface. The sensor sends out a sound pulse.

This pulse moves through the air above the oil. It bounces back when it hits the oil surface.

We measure how long it takes for the pulse to reach the oil surface and come back. Since we know the speed of sound, we can find the distance to the oil surface. We use this formula: distance = (speed of sound × time of flight) / 2. With the height of the tank and the measured distance, we can find the oil level.

Advantages

Ultrasonic sensors provide non-contact measurement. This means they do not touch the oil directly. This makes them good for measuring corrosive, thick, or dirty oils. There is no risk of damage or contamination.

They provide fast and accurate measurements. Industrial automation systems that need real-time data often use them. You can also easily connect them with other monitoring and control systems.

Limitations

Changes in temperature and humidity in the air above the oil can affect these sensors. These changes can impact the speed of sound and the accuracy of the measurement.

They need a clear line of sight between the sensor and the oil surface. Any blocks or air movement can disrupt the ultrasonic waves. This may lead to incorrect readings.

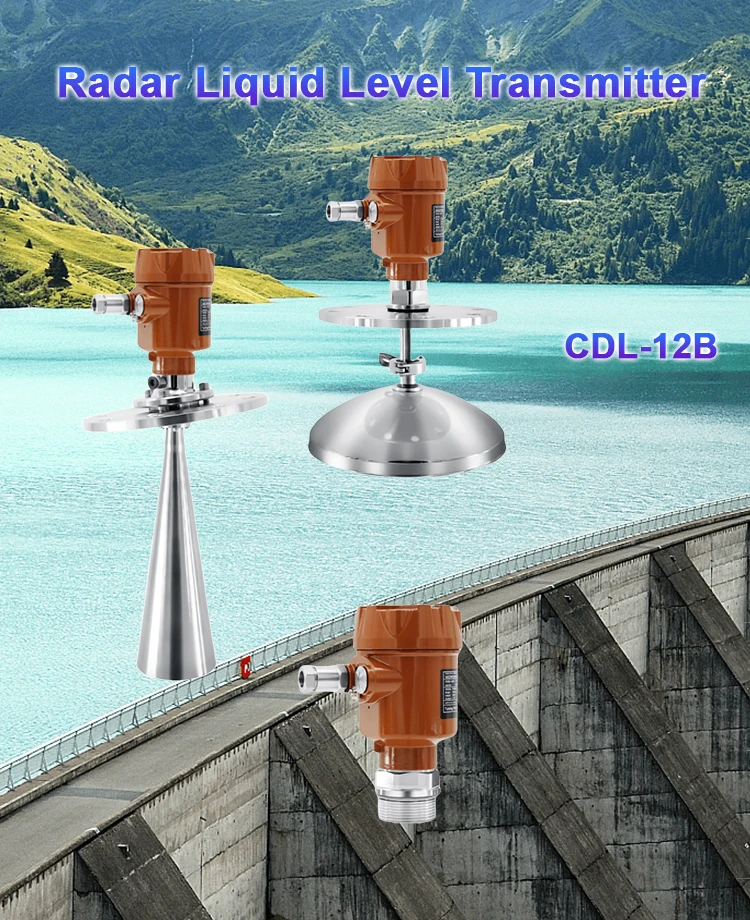

Radar Level Sensors

Principle and Operation

Radar level sensors work by using electromagnetic waves. They send out a radar signal, which is a type of microwave, toward the oil surface. When the signal hits the oil, it bounces back to the sensor.

We measure the time it takes to send and receive a signal. With the known speed of electromagnetic waves, we can find the distance from the sensor to the oil surface. Like ultrasonic sensors, knowing the tank’s height helps us figure out the oil level.

Advantages

Radar sensors are very accurate. They work well in many different conditions. This includes extreme temperatures, high humidity, and dusty or dirty places.

They are non – contact sensors, reducing the risk of wear and tear and the need for frequent maintenance. it can also measure oil levels with different properties, like viscosities and densities. They are good for large industrial uses, like big storage tanks.

Limitations

Radar level sensors cost more than some other methods. Installing and calibrating them can be tricky and may need special skills. Sometimes, vapor layers or foam on the oil surface can affect how the radar signal bounces back. This can cause incorrect measurements.

Hydrostatic Pressure – Based Sensors

Principle and Operation

Hydrostatic pressure sensors work on the idea that fluid pressure depends on its height. We place these sensors at the bottom of the oil tank. They measure the pressure from the oil above them.

The density of the oil and the height of the oil column relate to the pressure. To find the height of the oil column, you need to know the oil’s density. This value can be set in advance or measured. You can use the hydrostatic pressure formula: pressure = density × gravitational acceleration × height.

Advantages

These sensors are great for measuring oil levels in both small and large tanks. They give accurate and ongoing measurements.

They are easy to install at the bottom of the tank. It are less affected by foam or vapor on the oil surface than some other methods. They can also be used in underground storage tanks. It can be hard for other sensors to reach the top of the tank.

Limitations

They are sensitive to changes in oil density. This can happen because of temperature changes or contaminants. If the oil density changes, it can cause wrong level measurements.

You must calibrate the sensor correctly to match the oil’s specific properties. If the pressure-sensing part fails, it can give wrong readings.

conclusion

The way to measure oil levels depends on a few factors. These factors include the use, the size and type of the container, the oil’s properties, and how accurate the measurement needs to be. Each method has its pros and cons. People often use a mix of methods for accurate oil level monitoring.