What is an anemometer and what does it measure

Wind speed is an important part of the weather. It impacts many areas, such as weather forecasting, aviation safety, wind energy, and farming. The cup anemometer is an instrument measures the speed of the wind. It is a simple and effective tool.

Meteorologists and other experts have used this device for many years. This article will explain how a cup anemometer works. It will discuss its design, how it works, and the science behind its accurate wind speed measurements. The comes in different types of anemometers , include hot wire anemometers , sonic anemometer,mechanical anemometer and vane anemometers. How Does a Cup Anemometer Work?

The Design of a Cup Anemometer

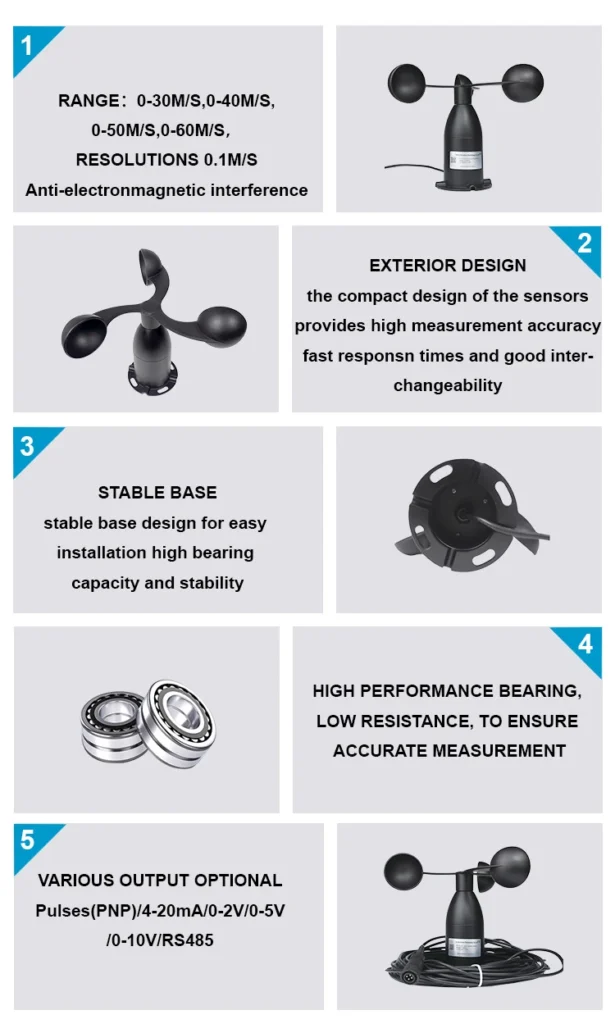

A typical cup anemometer has a vertical shaft. It has three or four round cups on top. Place these cups evenly around the shaft.

For a three-cup anemometer, space the cups 120 degrees apart. For a four-cup version, space them 90 degrees apart.

The horizontal arms extend from the central shaft and hold the cups. Designers make them so the open sides face the same direction. This setup makes sure the cups can catch the wind from all sides.

Manufacturers often make cups from light materials like plastic or aluminum. Using light materials is important. It helps the anemometer react quickly to changes in wind speed. This cuts down on delays in accurately measuring.

A bearing system holds the main shaft of the anemometer. This lets it spin easily with little friction. This free rotation is important for measuring wind speed accurately. Any resistance in the shaft can cause wrong readings.

Cup Anemometer Work Principles

The main idea of a cup anemometer is how the wind pushes on the cups. When the wind blows, it makes a pressure difference inside and outside the cups.

The side of the cup that faces the wind has higher air pressure. The other side has lower pressure. This difference in pressure creates a torque. This torque makes the cups rotate around the central shaft.

As the cups spin, their speed depends on the wind speed. The faster the wind blows, the bigger the pressure difference. This causes the cups to spin faster.

This link between wind speed and cup speed is important for measuring wind with a cup anemometer. To get a good wind speed reading, someone must calibrate the anemometer.

Calibration Process

Calibration is a crucial step in ensuring the accuracy of a cup anemometer. During calibration, technicians test the anemometer with known wind speeds. Researchers conduct this in a wind tunnel or a controlled setting.

They measure the speed of the cups carefully. People use tools like optical sensors or magnetic pickups for this. The data from these measurements shows how cup rotation speed relates to real wind speed.

People often show this relationship as a calibration curve or an equation. A simple linear equation can show how the cups’ revolutions per minute (RPM) relate to wind speed. We measure wind speed in meters per second.

Once you set up the anemometer, you can use this equation. It changes the cup rotation speed into a true wind speed reading for real use.

Data Acquisition and Measurement

In modern cup anemometers, data collection is often automated. An electronic sensor, such as a Hall effect sensor or an optical encoder, detects how fast the cups spin. These sensors create electrical signals that match the speed of the cups. An electronic circuit or a data logger then processes these signals and turns them into digital data.

Digital data can be sent in two ways. It can be sent wirelessly. You can also send it through a wired connection. This data can go to a remote locati0n, such as a weather station or a computer.

At the receiving end, someone looks at the data. It is then shown in an easy-to-understand way. This can be a number or a graph.

The graph shows how wind speed changes over time. Some advanced cup anemometers have built-in memory. This allows them to save past wind speed data for later use.

Limitations and Considerations

While cup anemometers are widely used and highly reliable, they do have some limitations. One of the main limitations is their sensitivity to wind direction. Cup anemometers measure wind speed.

However, they do not show which way the wind blows. To find out the wind direction, you need a different tool, like a wind vane.

Another limitation is that cup anemometers may not be very accurate in low or high winds. In low winds, the wind may not create enough force on the cups.

This can cause friction in the bearing system, leading to wrong readings. In strong winds, the cups can spin quickly. The anemometer may not measure wind speeds correctly above a certain level.

Weather factors like rain, snow, and dust can affect cup anemometers. These elements can collect on the cups and stop them from rotating. This can lead to incorrect measurements.

Regular maintenance is important. This means cleaning the cups and checking the bearings. It helps keep the anemometer accurate.

conclusion

The cup anemometer is a great tool that has changed how we measure wind speed. Its simple design uses aerodynamics and calibration. This helps us get accurate and reliable wind speed measurements for many uses.

The cup anemometer has some limits, but it is still a key tool. Meteorologists and environmental monitors use it. This tool provides valuable data. It helps us understand and connect with the natural world better.