What do we mean by a capacitive level gauge? How does a capacitive level sensor work?

A capacitive level gauge is a tool. It is also known as a capacitance-type level sensor or transmitter. This tool is used to measure levels. It works for both liquids and solids in tanks or vessels.

The gauge works based on capacitance. This means it has two conductive surfaces. These surfaces are separated by an insulating material. They can store an electric charge.

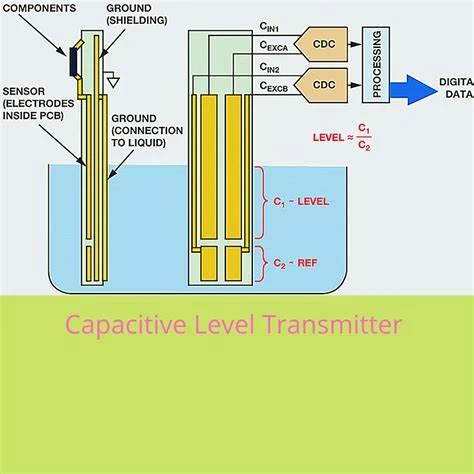

In this setup, the tank usually acts as one electrode. A probe inside the tank serves as the other electrode. When the material inside the tank, whether liquid or solid, touches these electrodes, it creates a dielectric. This dielectric changes the system’s capacitance.

The system uses special electronic circuits and software to find these changes. This helps measure the material level accurately and in real-time.

capacitive level sensor work principle

The working principle is based on changes in the dielectric constant. These changes affect capacitance.

When the substance fills the tank, it takes the place of air or vapor. The new material has higher permittivity. This causes the measured capacitance to increase.

We change these signals into standard signals, usually current signals. Then, we send them to control rooms. This gives us a central display, alarms, and automated control with other tools or computer systems.

Because it is versatile, we use a capacitive level gauge in many industries. These include oil and gas, chemical processing, and food production.

Engineers create level sensors for tough conditions. These sensors work well in high heat and high pressure. They also function in places that can freeze, clog, or form crystals.

They change material levels into current signals. These signals can resist interference from temperature, humidity, conductivity, and pressure changes. These sensors are very reliable and show strong resistance to interference.

These sensors can measure many types of media. This includes corrosive liquids like acids, alkalis, salts, and sewage. They can also handle high-temperature media, ranging from -40°C to +80°C, or even -70°C to +260°C if needed. Additionally, they work in high-pressure environments from -0.1 MPa to 0.5 MPa.

They can work well in sealed containers, no matter the thickness, weight, or pressure of the medium. Also, on-site calibration makes them easy to use and suitable for different industrial tasks.

**Key Features of Capacitive Level Gauges**

1. **Simple and Strong Design**:

These gauges have no moving or stretchy parts. This makes them reliable and easy to maintain. You usually do not need regular upkeep.

2. **Wide Signal Output Options**:

“Works with different system setups for more flexibility.”

3. **Adaptability to Extreme Conditions**:

This device is good for measuring liquid levels in high temperature and high pressure settings. It works well, no matter the temperature changes, liquid density, vessel shape, or pressure.

4. **Corrosion Resistance**:

This is very helpful for handling strong corrosive liquids, such as acids and alkalis.

5. **Protection Features**:

It has protections against too much current, high voltage, and wrong power connections.

The Working Principle of a Capacitive Level Sensor

A capacitive level sensor works by detecting changes in capacitance to measure the liquid level in a container. It has a metal rod that acts as one electrode of a capacitor. The container wall serves as the other electrode. The liquid and the gas above it act as the dielectric medium between these two electrodes.

The capacitance changes when the liquid level goes up or down. This happens because the liquid’s dielectric constant (ε₁) is different from the gas above it (ε₂).

For example, when ε₁ is more than ε₂, a rising liquid level increases the dielectric constant. This also raises the capacitance.

If the liquid level drops, the dielectric constant goes down. This causes a decrease in capacitance. This change in capacitance helps the sensor measure the liquid level accurately.

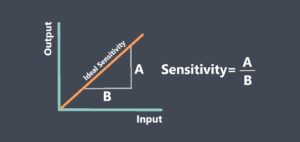

The sensitivity of capacitive level probes depends on the difference in dielectric constants of the liquid and gas. Stable values for ε₁ and ε₂ are important for accuracy. To reduce issues from conductive liquids, people often coat the metal rod with an insulating layer. This coating helps lower safety risks and measurement errors.

Manufacturers make capacitive level gauges to be small. They allow for remote transmission and dispatching. These gauges work well in corrosive or high-pressure environments.

Advantages and Disadvantages of Capacitive Level Sensors

Capacitive level sensors measure liquid levels by detecting changes in capacitance between two electrodes. Their performance relies on the difference in dielectric constants of the gas and liquid. If these constants change a lot or are unstable, inaccuracies can happen.

Capacitive level gauges use metal electrodes with an insulating layer. This layer stops errors from conductive liquids. It also ensures reliable measurements and safety.

Their small design makes them good for high-pressure conditions and tough media. Features like remote transmission and calibration adjustments add flexibility to these instruments.

Capacitance level gauges are easy to use, efficient, and flexible. They help find liquid levels in many industries. When used correctly, they provide reliable performance.

In summary, this breakdown shows how capacitance level gauges work. It covers their features, benefits, and drawbacks. Knowing these points will help you decide how to use them. We hope this information is helpful for you.