how does ultrasonic sensing work

Overview of Ultrasonic Sensors

Ultrasonic sensors are devices that convert ultrasonic signals into other forms of energy, typically electrical signals. Ultrasonic waves are mechanical waves. They have frequencies higher than 20 kHz. These waves have key features.

They have a high frequency, a short wavelength, and low diffraction. They also have great directivity, which helps them travel in a specific direction.

Ultrasonic waves are very good at passing through liquids and solid materials. This includes materials that block visible light. When these waves hit impurities or surfaces, they create echoes that reflect back.

They create a Doppler effect when they bounce off things that are moving. Ultrasonic sensors are used widely in many industries, national defense, and biomedicine because of these features.

Classification of Ultrasonic Sensors

A sensor is a device that detects changes in the environment. It converts this information into usable signals, usually electrical, based on specific rules. Sensors typically have two main parts: a sensitive element and a conversion element.

They help gather and change measured information into signals. You can send, store, show, or use these signals in control systems. They are the basic part for using automation in detection and control processes.

There is no one standard for classifying sensors. Here are three common ways to group them:

1. **By Measurable Physical Quantity**

You can group sensors based on what they measure. This includes displacement, force, speed, temperature, flow rate, and the makeup of gases.

2. **By Working Principle**

This method includes different types of sensors. These are resistance-based sensors, capacitive sensors, inductive sensors, and voltage-based sensors. It also includes Hall effect sensors, photoelectric sensors, gratings, and thermocouples.

3. **By Output Nature**

– **Switch-Type Sensors** Give simple outputs like “on/off” or “1/0.”

– **Analog Sensors** Create signals that are steady.

– **Digital Sensors** Output discrete pulse or coded signals.

Among these different types of sensors, ultrasonic sensors are especially important for their many uses in daily life. One of their most useful uses is in car reversing radar systems.

Ultrasonic Sensors: Fundamental Concepts

Ultrasonic sensors use special sound waves to find objects. They create and receive ultrasonic waves. You use a device called an ultrasonic sensor to do this. People also refer to it as an ultrasonic transducer or probe.

Core Components of Ultrasonic Probes

The probe mainly has piezoelectric wafers. These wafers can send and receive ultrasonic waves. The main part of the probe is a piezoelectric chip. It is covered in a plastic or metal case.

Manufacturers can use different materials to make the wafer. These include piezoelectric crystals that use electrostriction and nickel-iron-aluminum alloys that rely on magnetostriction. Notably, lead zirconate titanate (PZT) is a common choice for electrostrictive materials.

Sensors made with piezoelectric crystals can work in two ways. They can turn electric energy into mechanical vibrations. This process creates ultrasonic waves.

They can also turn received ultrasonic waves back into electrical energy. These sensors can work as transmitters, receivers, or both based on their design.

Structure of Ultrasonic Sensors

An ultrasonic sensor system has a few main parts:

1. **Transmitting Sensor (Wave Transmitter):**

Responsible for sending out the ultrasonic wave. This sensor typically has a ceramic vibrator transducer that is around 15 mm wide. The ceramic vibrator turns electrical energy into ultrasonic waves. These waves move through the air.

2. **Receiving Sensor (Wave Receiver):** Comprised of a transducer connected to an amplifier circuit. This transducer takes in ultrasonic waves. It makes mechanical vibrations and turns them into electrical signals. These signals are the output for the receiving sensor.

3. **Control Unit:** Manages key tasks like pulse chain frequency, duty cycles, sparse modulation, counting, and distance detection.

4. **Power Supply Unit:** “Supplies the energy needed for the system to work.”

Ultrasonic sensors work well by combining these elements. They can find objects or changes in the environment in many ways.

Applications in Reversing Radar Systems

One common use of ultrasonic sensors is in car reversing radars. These systems make driving safer. They can see obstacles close by when they park or back up.

Using ultrasonic sensors in these systems helps measure distance and find objects accurately. This makes cars more convenient and secure.

Working Principle of an Ultrasonic Sensor

Ultrasonic sensors are devices that work using the special features of ultrasonic waves. Sound waves are vibrations that move through a material.

Ultrasonic waves are sound waves that have frequencies higher than 20,000 Hz. This speed of sound is higher than what humans can hear. Because people cannot hear them, we refer to such sound waves as ultrasonic.

Ultrasound is a type of sound that travels through an elastic medium. It has two main forms: transverse waves and longitudinal waves. Many industries use vibrations that last a long time in their work.

Ultrasonic waves can travel through gases, liquids, and solids. However, their speed changes based on the material. These waves also show effects such as refraction, reflection, and attenuation when they are sent out.

The basic principles of ultrasonic waves are like those of sound waves. These principles are reflection, refraction, diffraction, and scattering. Ultrasonic waves have unique features that set them apart from sounds we can hear.

1. **Propagation Characteristics**:

Ultrasonic waves do not bend well. They move in a straight line through even materials. This effect becomes more pronounced as the wavelength shortens.

2. **Power Characteristics**:

As sound travels through the air, it makes air particles vibrate and do work. For waves with the same strength, higher frequencies give more power. Ultrasonic waves can carry more power than regular sound waves. This is because they have a high frequency.

3. **Cavitation Phenomenon**:

When ultrasonic waves move through liquids, they cause quick movements of liquid particles. This creates small cavities. These cavities grow and shrink quickly. This leads to strong collisions between particles.

The pressures can reach thousands to tens of thousands of atmospheres. This interaction raises the temperature of the liquid a lot. This can help mix liquids that usually do not mix, like water and oil.

It also speeds up how fast solutes dissolve and makes chemical reactions happen faster. We call this whole process ultrasonic cavitation.

Key Features of Ultrasound

1. Ultrasound moves in a certain direction. This helps it concentrate energy in one spot.

2. It can move through different materials and travel long distances.

3.The moderate interaction between ultrasound and the medium makes it a useful tool. It can check the medium’s state for diagnosis or change it.

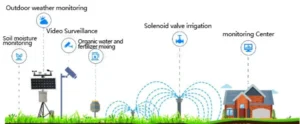

Role of Ultrasonic Sensing Technology

Throughout history and industrial revolutions, sensing technology has always been an important tool in many areas. Sensors are very important. They connect technology to real-life uses and can be found almost everywhere.

As sensor development continues, they are evolving from simple judgment tools to ones that can learn and be creative. Experts think that ultrasonic sensors will improve a lot in the future. These sensors are known for being useful and versatile.

They will move toward better precision and improved positioning skills to meet society’s changing needs. In this change, sensors with new features will play a bigger role in shaping future technologies.

Ultrasonic Wind Sensor

Ultrasonic wind sensors are advanced tools. They measure wind speed and direction. They do this by detecting how long ultrasonic waves take to travel in the air.

Unlike traditional mechanical anemometers, such as cup anemometers, these devices do not have moving parts. This makes them more dependable and able to work in various settings. Here is a clear summary of their main traits.

Ultrasonic wind sensors are special due to their unique design and the benefits they provide. They fix the issues with old wind-measuring tools.

No Moving Parts, High Reliability

They take out mechanical parts such as rotating cups or vanes. These parts can wear out, jam, or get damaged in tough conditions like sand, ice, or strong winds. This design makes it easier to maintain and helps the sensor last longer. Normally, the lifespan is 5 to 10 years with regular use.

Fast Response & High Measurement Accuracy

Ultrasonic waves move quickly. This allows the sensor to detect wind changes in real-time. It can respond in just 0.1 to 1 second.

Most models have a wind speed error of plus or minus 2% or less. They also have a wind direction error of ±3° or less. This is important for situations that need high precision, such as aviation and weather forecasting.

Wide Operating Range

They work well in very tough environmental conditions.

Wind speed usually ranges from 0 to 60 m/s. This is similar to Beaufort Scale 12, which is “hurricane-level.” Some industrial models can handle speeds up to 100 m/s.

Depending on temperature and humidity : It works in temperatures from -40°C to 85°C. It can handle 0–100% humidity, even in heavy rain or fog. This is possible because of its anti-condensation designs.

Corrosion and Dust Resistance: Most products have an IP65 or IP67 rating. This means they are waterproof and dustproof. Some use anti-corrosion materials, like 316L stainless steel, for marine or coastal use.

Low Power Consumption & Easy Integration

Low-power circuit designs are great for battery or solar-powered remote monitoring systems. They typically use less than 1W in standby mode. These designs also work with common communication protocols like RS485, Modbus, LoRa, and 4G. This makes it easy to connect with data loggers, IoT platforms, and control systems.

Multi-Parameter Detection (Optional)

Many advanced models use extra sensors to measure things like air temperature, humidity, and atmospheric pressure. They also track PM2.5. This device provides all the weather and environmental data you need.

Ultrasonic Radar Level Sensor

Ultrasonic radar level sensors are non-contact devices that measure level sensing. They use ultrasonic waves that have a high frequency. These sensors can detect liquids, solids like powders and granules, or slurries in tanks, silos, or containers.

The sensor measures the time it takes to send ultrasonic pulses and receive their echoes. This helps it find the target level accurately. Here are the main features that make them popular in many industries:

1. Non-Contact Measurement, Minimal Material Interference

Works without touching the measured substance. This prevents issues like wear, clogging, or rust from direct contact. This is important for harsh fluids like acids and alkalis, thick materials like oil and sludge, or rough solids like cement powder and coal.

It prevents contamination, making it perfect for food and drink, like milk and syrup. It is also great for pharmaceutical uses where cleanliness and product purity are essential.

2. Wide Measurement Range & High Accuracy

The standard models have a flexible measurement range from 0.1m to 10m. Industrial-grade versions can measure 20m or more. They can live in small tanks, like lab containers, and large silos, like grain storage.

Delivers high precision: Most models have an accuracy of ±0.2% of the full scale (FS) or better. Some advanced versions reach ±0.1% FS. This meets the strict control needs of industries such as chemical processing, oil and gas, and water treatment.

3. Strong Environmental Adaptability

Resists harsh operating conditions:

Temperature resistance: Works well in temperatures from -40°C to 80°C. High-temperature models can handle up to 150°C. This makes them good for cold storage and hot oil tanks.

Weatherproof and dustproof: Most have ratings of IP65, IP67, or IP68. This allows them to work well in outdoor tanks. They can handle rain, snow, and dust. They also perform well in humid indoor places, like wastewater treatment plants.

Immunity to outside disturbances: Less affected by things like light, electromagnetic interference (EMI), or small surface waves in liquids. This makes it better than optical or capacitive sensors in complex situations.

4. Easy Installation & Low Maintenance

Simplified mounting: It can be installed from the top or side of tanks. No complex changes to existing equipment are needed. Most standard applications do not need calibration. You just need to set simple parameters using a screen or software.

Low maintenance needs: Since there are no moving parts like floats or probes, you won’t need to repair or replace parts often. Routine maintenance includes cleaning the sensor’s transducer now and then. This helps get rid of dust or moisture. This improves echo reception.

5. Versatility for Diverse Media

Compatible with multiple medium types:

Liquids: Works with clean water, fuels like gasoline and diesel, chemicals, and slurries that have low solid content.

Solids: Works well with free-flowing powders like flour and plastic pellets. It also handles granular materials like sand and grains. However, performance may change a bit for very absorbent solids. Some models have echo-enhancement technology to help with this.