What Is a Turbidity Sensor and How to Choose One?

To understand a turbidity sensor, you first need to know what turbidity is. Turbidity shows measure water quality. It measures how many small particles are in a water sample.

You can find this out by seeing how much incident light scatters in the water. More light scattering means higher turbidity. Turbidity is often caused by suspended solids, sediment, clay, and organic or inorganic materials. It can also come from dissolved compounds and algae.

High turbidity often needs water purification for both industry and home use. Reducing turbidity helps lower harmful substances, bacteria, and viruses in the water.

Why Measure Water Turbidity?

**Turbidity in Drinking Water**

High turbidity in drinking water can cause serious health risks, especially stomach problems. This happens because viruses and bacteria can stick to small particles. These particles make it hard to clean the water, making it unsafe to drink.

Surface water and groundwater often have these particles and germs. They need treatment before they are safe to drink. Drinking water standards say that turbidity should not go over 1 NTU (Nephelometric Turbidity Unit).

The World Health Organization (WHO) says safe drinking water should have a turbidity level below 1 NTU. If it is higher than this, more treatment is needed to make it usable.

To keep these standards, water treatment plants often use turbidity probes in drinking water systems. These devices check water quality and quickly alert operators to any problems with equipment or pipes. They do this when treated water does not meet the required standard.

**Turbidity in Industrial Water**

Monitoring turbidity in industrial processes is very important. High turbidity can harm machinery, raise energy use, and shorten equipment life.

For example, suspended solids in water can raise friction in pumps and pipes. This causes more wear and tear. Impurities can harm parts like transmission machines and agitators. This results in lower efficiency and a shorter lifespan over time.

High turbidity often means there is too much algae, bacteria, or other organisms. These can build up on the inner walls of pipelines. This buildup can cause blockages and make operations less efficient.

To improve system management, industrial cooling water systems use side-stream filtration. This helps keep water turbidity levels at or below 5 NTU.

**Turbidity in Rivers and Reservoirs**

Rivers, lakes, and reservoirs with too much turbidity face big ecological problems. Less light reaches the water, which harms aquatic plants. This change disrupts ecosystems that rely on fish and shellfish. These animals need algae for food.

High turbidity makes it harder for fish to take in dissolved oxygen. Researchers have looked into this problem in places like Chesapeake Bay in the United States.

What Is a Turbidity Sensor?

A turbidity meter is a device that measures how many particles are in a liquid. It uses light to do this.

As light goes through a liquid sample, the particles in it affect its path. They can either absorb the light or reflect it at different angles and strengths. Based on these interactions, the device calculates the turbidity level within the liquid.

How Does a Turbidity Sensor Work?

The main idea of a turbidity sensor is to see how light interacts with particles in water. This interaction changes light in two main ways: scattering and absorption.

– **Scattering:**

Suspended particles change the direction of incoming light at different angles and strengths. Some of this scattered light goes to a detector in the turbidity sensor.

– **Absorption:**

Some particles absorb certain wavelengths of light. This reduces the light’s intensity as it moves through the solution. Different particles show unique absorption patterns based on what they are made of.

**Turbidity Units and Sensors: An Overview**

When measuring turbidity, you will often see units like NTU (Nephelometric Turbidity Units), JTU (Jackson Turbidity Units), or FTU (Formazin Turbidity Units). These units have different measurement standards, but they are related through these conversion relationships:

| **Unit** | **JTU (degrees)** | **FTU (NTU)** | **SiO₂ (mg/L)** |

|——————-|——————-|—————|——————|

JTU (degrees)** | 1 | 19 | 2.5 |

FTU (NTU)** | 0.053 | 1 | 0.13 |

SiO₂ (mg/L)** | 0.4 | 7.5 | 1 |

– **JTU (Jackson Turbidity Unit):** This unit uses diatomite or kaolin as a standard for turbidity. They measure it with the Jackson candle turbidimeter.

– **NTU (Nephelometric Turbidity Unit):** This unit uses methyl wax as a reference for turbidity. A scattered light nephelometer measures it.

**FTU (Formazin Turbidity Unit):** This is measured by a device called a transmitted light nephelometer.

Types of Turbidity Sensors

Turbidity measurement uses three main types of sensors. Each type has its own specific use.

1. **Absorption Turbidity Sensors**

Absorption turbidity sensors detect how clear a liquid is by checking how much light is absorbed. They work on a simple principle:

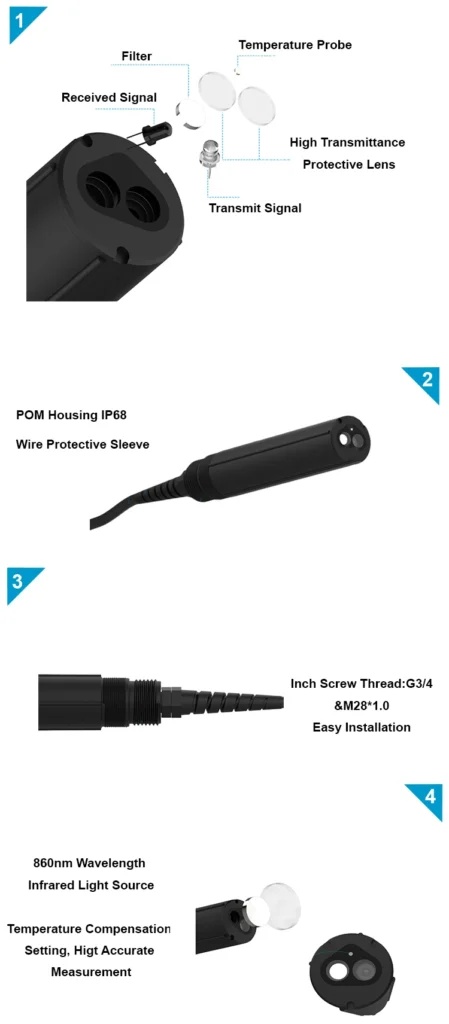

– **Light Source:** An LED sends light at a specific wavelength to the liquid sample.

– **Interaction with Particles:** Suspended particles in the liquid absorb part of the light.

– **Photodetector:** A photodetector measures how much light is left after it passes through.

**Output:** The sensor measures turbidity by comparing the strength of light that comes in and the light that goes out. It uses specific standards for this comparison.

**Units:** Sensors often show measurements in NTU or FTU. This depends on how they are calibrated and how they work.

**Applications:** These sensors are used to watch the environment. They help with water treatment, food and beverage and drink production, industrial processes, and lab testing.

2. **Nephelometric Turbidity Sensors**

Nephelometric sensors measure level of turbidity by looking at how light scatters from particles in a liquid sample. The process includes:

– **Light Source:** An LED lights up the sample.

– **Light Scattering:** Particles in the air scatter light in different directions.

– **Detection:** Photodetectors at certain angles measure how much light is scattered. This relates to the size and amount of particles.

**Output:** The calibration standard decides if results are shown in NTU or FNU (Formazin Nephelometric Units).

– **Applications including:** These sensors are great for measuring clear liquids, like drinking water and medicines.

3. **Suspended Solid Turbidity Sensors**

Total suspended solid (TSS) turbidity sensors measure the amount of solid particles in a liquid sample. Researchers usually record these measurements in milligrams per liter (mg/L) or parts per million (ppm).

The working principle includes:

– **Light Emission:** An LED sends out light at a certain wavelength into the sample.

– **Scattered Light Measurement:** Small particles in the air scatter light. Sensors check how much light is scattered.

– **Concentration Calculation:** The amount of scattering relates to the concentration and size of suspended solids. This gives a calculated TSS value.

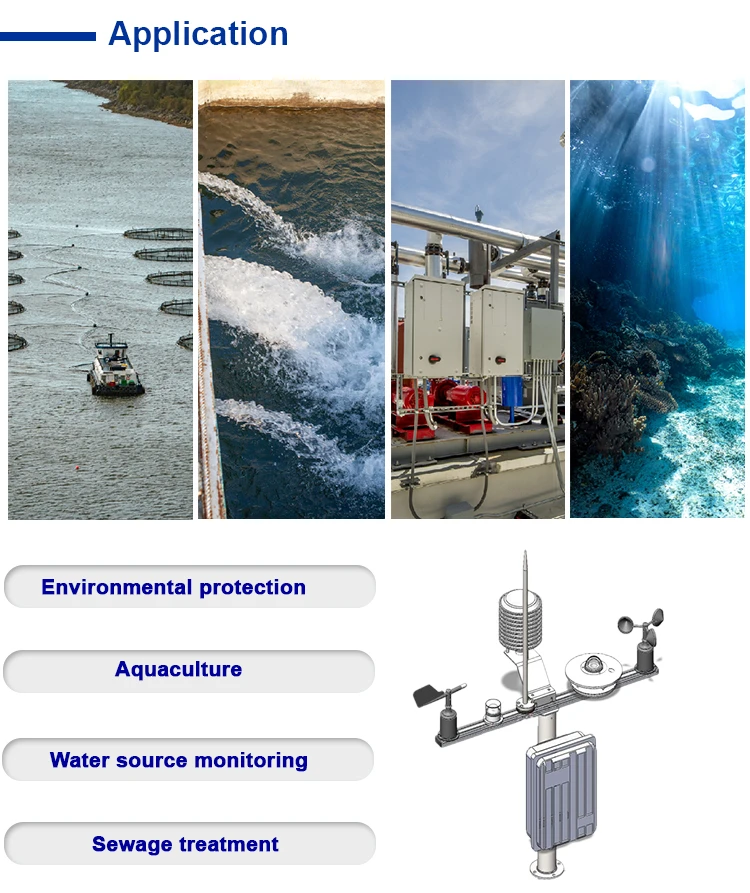

– **Applications:** These sensors are strong and work well in dirty water. They are good for aquaculture, industrial wastewater treatment, and controlling eutrophication.

Applications Across Industries

Turbidity sensors are important in many fields. They help measure how clear liquids are. Many industries use these sensors. They are used in water quality checks, food and drink processing, industrial production, wastewater treatment, and aquaculture.

Choosing the best turbidity sensor for different measuring points involves some key factors. This ensures it meets your needs and works well. Here are some factors to help you decide:

1. Measurement Range

Find out the turbidity values you need to monitor. Check if the sensor can handle those levels. Different sensors work best for certain wide range. Some sensors detect low turbidity better, while others are good at measuring high turbidity.

2. Accuracy

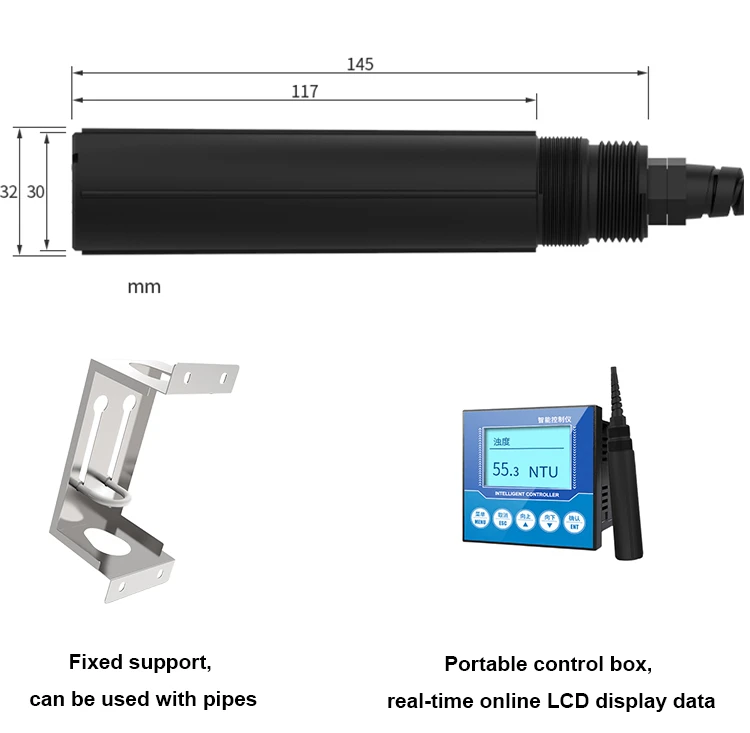

Accuracy is very important, especially when you need precise readings. Choose a sensor with high accuracy for reliable data. The Coda CDT-19B turbidity sensor has a built-in temperature compensation feature.

This feature helps lessen the impact of temperature changes. It also gives more steady readings.

3. Calibration Needs

Make sure you understand the calibration needs for the sensor. Proper calibration with standard turbidity solutions is key for accurate measurements. Ensure the calibration process works with your resources and setup.

4. Sample Characteristics

Check the type of sample you are measuring. If the sample has large particles or may cause problems, choose a sensor made for these cases. This choice will prevent clogging and keep measurement quality high.

5. Environmental Conditions

Think about where the sensor will be used. In tough places or areas with big temperature changes, people need extra features. A strong design and good temperature control help keep it working accurately and reliably.

6. Response Time

Response time may not matter for most applications. However, it is very important in situations that need real-time data to control processes. A sensor with a swift response can enhance operational efficiency.

7. Maintenance Requirements

Look for sensors that are easy to care for or have automatic cleaning. This will lower labor costs and downtime. It will also help the sensor last longer.

8. Budget Considerations

While staying on budget is important, focus on accuracy, reliability, and suitability more than just cost. Avoid spending too much on extra features, but do not give up on essential functions that provide long-term value.

**Additional Considerations:**

– **Brand Reputation**: Choose well-known brands that have a good track record in measuring water quality.

– **Data Integration**: Make sure the sensor works with your current data platform for easy monitoring.

– **Installation Method**: Choose a sensor that fits your needs for simple setup and use.

Coda is a trusted maker of water quality sensors. They offer custom solutions and expert support. If you have questions or need help, reach out to their team.