What Is A liquid level sensing ? | liquid level detection

A liquid level sensor is a useful tool. It measures and checks liquid levels in many industries. This article will look at the functions, types, uses, benefits, and future of liquid level sensors.

How Do Liquid Level Sensors Work?

Liquid level detectors sense changes in pressure, capacitance, or conductivity. These changes show how much liquid is present. The levels change as the liquid goes up or down.

The sensor has a probe that makes contact with the liquid. When the liquid level changes, it impacts the area near the sensor. This change makes an electrical signal. The system then turns this signal into a data point that shows the liquid level.

Varieties of Liquid Level Sensors:

There are many kinds of liquid level detectors. Each type is made for specific uses. Some of the most common types include:

a) Float Switches:

Float level switches are mechanical devices. They have a floating object linked to a switch points. When the liquid level goes up, the float moves up.

When it gets to a certain continuous level, it turns the reed switch on or off. People often use these switches in tank levels and wells.

b) Capacitive Level Sensors:

Capacitive level sensors work by using capacitance to measure liquid levels. These sensors are made up of electrodes, an oscillator, and circuits.

When the liquid touches the electrodes, it changes how much capacitance there is. This change helps measure the liquid level. You can use capacitive sensors in tanks and pipes. They also work with non-conductive liquids.

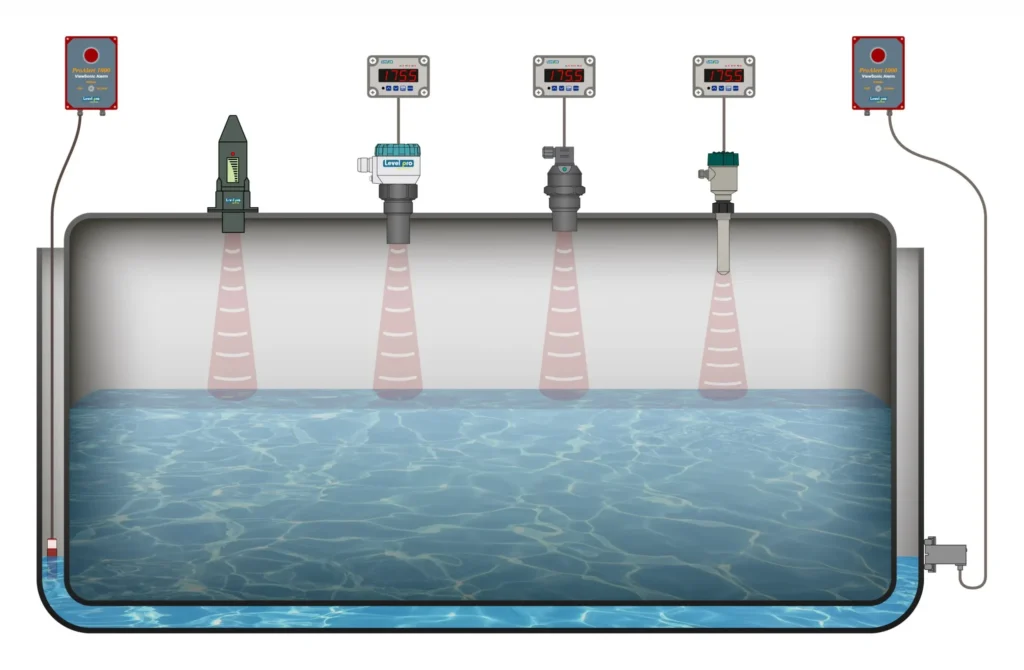

c) Ultrasonic sensor:

Ultrasonic wave sensors use sound waves to measure how high liquids are. They send out high-pitched sounds that bounce off the surface of the liquid. The ultrasonic level sensors then measures how long it takes for the sound waves to come back.

d) Pressure Sensors:

These stainless steel devices measure liquid levels by sensing the pressure from the liquid. When the liquid level changes, the pressure on the sensor changes too.

This change is now shown as level information. Pressure sensors can be used in many places. You can find them in tanks, reservoirs, and factories.

e) Optical Level Sensors:

Optical level sensors use light to measure how high liquids are. These sensors have a transmitter and a receiver placed at different heights.

When the liquid level monitoring goes up, it breaks the light beam. This sends a signal to show how high the liquid is. Optical level sensors are often used in water tanks, vending machines, and drink dispensers.

Uses of Liquid level sensing device:

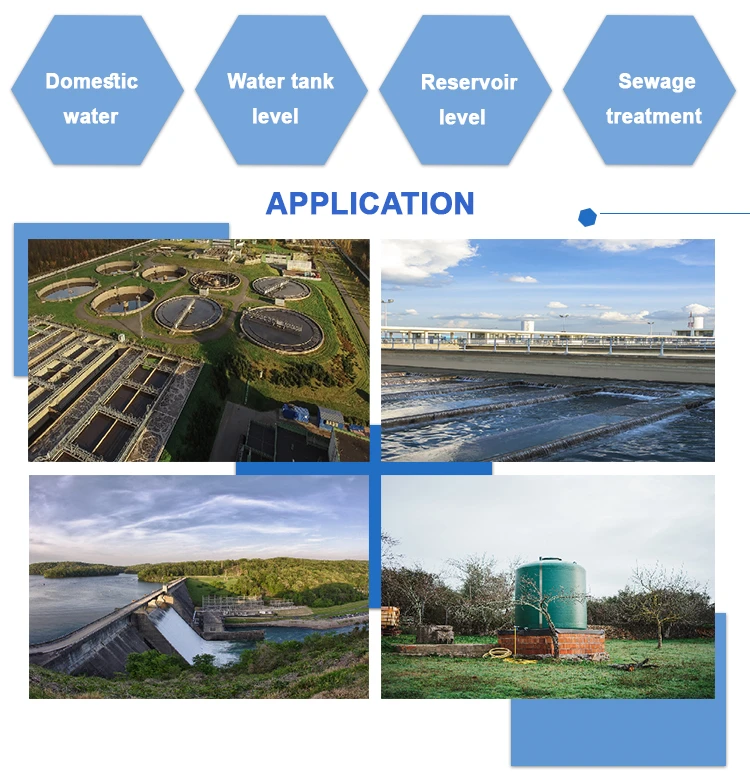

Liquid level detection are utilized across a wide variety range of industries and sectors, such as:

a) Oil and Gas:

In the oil and gas industry, liquid level detectors play a key role. They help keep an eye on storage tanks and check fuel levels. These sensors help stop overflow and leaks. They are key for managing inventory, improving logistics, and enhancing safety.

b) Agriculture:

Farmers use liquid level detectors to check water levels in their fields. These sensors help with irrigation, watering animals, and storing pesticides. They support good water management by making sure the right amount of water is used.

c) Pharmaceuticals:

In the pharmaceutical world, liquid level detectors are key for accurate dosing. They help stop contamination and keep quality control during manufacturing. These sensors are important for storing and sharing medications.

d) Food and Beverage Industry:

In food and drink factories, workers use devices to check liquid levels. These sensors check and manage the amounts of ingredients. The ingredients are water, oil, and other key liquids. They help keep production steady and correct.

e) Waste Management Sector:

Waste management uses liquid level detectors in waste containers, sewage systems, and landfills. These sensors check the levels of liquid waste. They help stop overflow and lower environmental risks.

Advantages of Implementing Liquid level sensing device:

Using liquid level detectors offers many benefits, such as:

a) Streamlined Operations:

Liquid level detectors help keep track of liquid levels accurately and in real-time. They stop overfilling and underuse. This makes processes better and cuts downtime.

b) Financial Savings:

Liquid level sensors help save money by giving accurate measurements. They stop spills and waste. These sensors remove the need for manual checks and prevent damage from overflows.

c) Enhanced Safety:

Liquid level detectors help keep things safe. They provide early warnings about leaks, blockages, or strange liquid levels. Finding problems early allows for quick action. This helps prevent accidents and dangers.

d) Process Control and Automation:

When used with automation systems, liquid level detectors help control processes smoothly. They can set off alarms, start pumps, or control valves based on liquid level limits.

e) Environmental Compliance:

In industries with strict environmental rules, liquid level detectors play a key role. They help meet discharge standards and stop harmful materials from entering the environment.

Future Innovations in Liquid level sensing device:

As technology gets better, high frequency liquid level sensors are changing as well. Here are some possible changes for the future:

a) Internet of Things (IoT) Integration:

Liquid level detectors with IoT features let you check and analyze data from a distance. This connection helps manage inventory. It also makes it easier to fix problems from far away.

b) Nanotechnology:

Progress in nanotechnology may lead to tiny liquid level detectors that are more precise and sensitive. Smaller devices could use these sensors, creating new opportunities in many fields.

c) Wireless Communication:

Using wireless technology makes liquid level detectors easier to use. It helps them work better with the systems they have now. This also makes it simpler to install and keep up.

d) Advanced Sensing Technologies:

Ongoing research may lead to new liquid level detectors. These sensors will use advanced technologies like microwave, radar, or laser. These tools could give more accurate and reliable liquid level measurements.

e) Real-time Data Analysis:

We can now check liquid levels in real-time thanks to better data analysis and machine learning. This progress helps us know when maintenance is needed. It also makes processes easier and boosts system performance.

Conclusion:

Liquid level sensors are useful tools in many industries. They help keep track of liquid levels. There are various types of sensors for different needs. Using these sensors has many benefits. They can make things safer and reduce costs.

Future innovations in liquid level detectors will focus on a few key areas. These include better connections and smaller sizes. There will be new improvements in sensing technologies. Real-time data analysis will be a key priority as well.

Many challenges affect OEM sensors. We need to train specialists in certain areas to solve problems. We also need sensor solutions for issues with environmental monitoring systems.

Our vision is the base for our sensor solution. It guides all parts of our business. It tells us what to do for steady, quality growth.

What makes our sensor solution stand out from other products? How does it meet your needs or wants? Is it easy to use? Does it make life simpler?

An OEM sensor needs the right sensor solution to work well. Since it is used often, it is important to choose one that is high quality.