Description

CDR-10A Liquid Gas Pressure Sensor

CDR-10A A pressure sensor is a device designed to measure the pressure of gases or liquids. By converting pressure into an electrical signal, it enables monitoring, control, and data collection across a wide range of applications. This article delves into the working principles, types, applications, and limitations of pressure sensors.

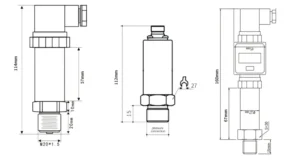

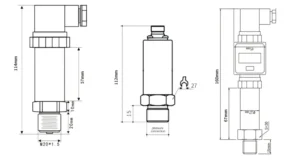

Installation & size

Pressure sensor operate on the piezoresistive effect. A piezoresistive element, typically made of silicon, changes its electrical resistance when pressure is applied. When pressure deforms the silicon structure, the resistance of the element changes proportionally. This change in resistance is then converted into an electrical signal, which can be measured and analyzed.

Application

◉Pressure sensors play a vital role in modern vehicles. They are used for tire pressure monitoring systems (TPMS) to ensure optimal tire pressure, improving fuel efficiency and safety. They also measure manifold absolute pressure (MAP) in the engine, helping the engine control unit to optimize fuel injection and ignition timing, enhancing engine performance.

◉In industrial settings, pressure sensors are used in various manufacturing processes. For example, in the oil and gas industry, they monitor the pressure of pipelines to prevent leaks and ensure safe operation. In the food and beverage industry, they control the pressure during bottling and packaging processes to maintain product quality.

◉Pressure sensors are used in medical devices such as blood pressure monitors, both in clinical settings and for home use. They are also used in ventilators to measure the pressure of the air being delivered to patients, ensuring proper respiratory support.

Pressure Sensor News

The Working Principle And Applications Of Gas Sensors