Maintenance and Troubleshooting of Tipping Bucket Rain Gauge

Measuring precipitation is a key part of weather observation. Precipitation data is important for climate analysis. It also helps prevent and reduce the impact of disasters.

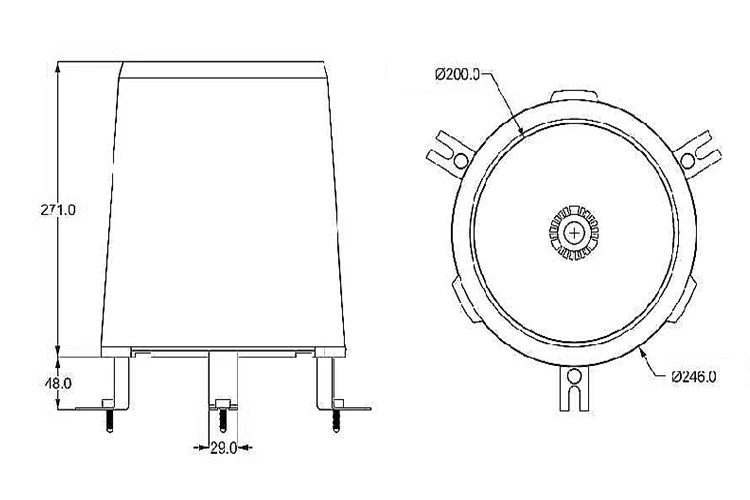

A tipping bucket rain gauge helps automatically track rain and snow over time. This tool makes it easier for observers. It has key parts like a shell, filter, funnel, tipping bucket, terminal block, leg bracket, reed switch, and base. It measures precipitation by reacting to weight changes.

This guide shows how to care for tipping bucket rain gauges and fix common problems. It aims to help agricultural workers solve issues easily, which will boost efficiency.

1. **Daily Maintenance**

(1) Cleaning and Protection

The tipping bucket rain gauge works well in tough outdoor conditions. To keep it in good shape, wipe the inside of the rain port with a soft cloth regularly.

Clear leaves and other objects from the gully quickly. This will help the water flow smoothly.

If you don’t use the instrument for a long time, cover its opening. This will keep it safe from debris.

To keep the instrument in good shape, clean it once a month. Do a deep clean every three months.

(2) Post-Heavy Precipitation Checks

Check the gauge after each heavy rain to avoid overflow.

If the rain is too heavy for the measuring device, drain the extra water from time to time.

In dry weather with no rain, cover the bucket. Uncover it when the weather improves.

(3) Data Accuracy Analysis

Keep an eye on rainfall data for any unusual patterns. If the data seems off, do field tests quickly.

Unplug the rain gauge’s data cable. Then, connect it to a rainfall calibrator.

Reset the calibrator. Use a special measuring cup to measure 10 mm of water. Slowly pour this water into the inner cylinder. Do this at a rainfall intensity of 2 to 4 mm per minute.

Repeat the process three times. Calculate the errors each time. Make sure the errors do not exceed 4%. We consider a test accurate if it is within this range.

2. **Fault Maintenance**

(1) Damaged Parts

Damage to filters, funnels, or cracks in the tipping bucket can greatly affect measurement accuracy.

Replace broken parts and adjust the instrument after fixing it.

(2) Wear of Hidden Parts

Hidden wear in parts, like rotating shafts or rusting filters, can change rainfall measurements. Regularly check and adjust these parts to maintain accuracy. This helps keep performance steady over time.

(3) Dust Buildup

Clean the visible parts of the instrument often to stop dust from building up.

Precision parts can be tough to clean and may gather dirt over time. Do careful internal checks to remove hidden dust during maintenance.

(4) Reed Switch Sensitivity Issues

If the reed switch does not work well or consistently, check the following:

Make sure the reed switch lines up with the sensing part. You should hear a clear clicking sound when the tipping bucket moves past the reed switch.

Check the reed switch for cracks or any visible damage.

Check that the solder joints on the reed switch are tight.

(5) Wiring Problems and Circuit Faults

If there is no mechanical damage but rain errors keep happening, check the circuit board and wiring. Look for bad connections or faults that could cause issues.

The tipping bucket rain gauge has greatly improved how we measure rainfall for farming and industry. However, it can develop faults over time. Regular maintenance is important to keep it working well.

Keeping a record of troubleshooting experiences will help with future repairs. This will speed up response times and give us reliable data.