How to Test a Wind Speed Sensor

Wind speed sensors are important in many industries. These areas include weather forecasting, renewable energy, and building design. They give exact measurements of wind speed. This helps in making important decisions based on reliable data.

Wind speed sensors, like all measuring devices, need to be tested regularly. This helps keep them accurate and reliable. Here is why testing is important. This also includes a simple guide to help you assess these sensors.

The Basics of Wind Speed Sensors

Anemometers are wind speed sensors. They measure how fast the wind is blowing. They can also indicate which way the wind is blowing.

These instruments work by changing wind movement into an electrical signal. This signal is then used to show the wind speed in real time.

There are different types of anemometers. These include cup anemometers, vane anemometers, and sonic anemometers. Each type has its own strengths and uses.

Accurate data from these sensors is very important. Even small mistakes can lead to errors in modeling and making decisions. Routine testing makes sure the devices work well and reliably.

Calibrating a Wind Speed Sensor

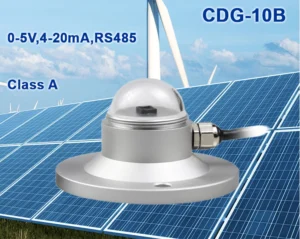

One of the most important parts of testing a wind speed sensor is calibration. Calibration means checking the sensor’s readings against a standard. This ensures that the readings are accurate.

This usually means testing the sensor with controlled wind speeds. We see if the output is what we expect. Calibration setups can use special tools. These tools include calibration chambers and small wind tunnels that can be moved easily.

Environmental factors such as temperature, humidity, and altitude can affect how well the sensor works. They do this by changing air density and viscosity. Calibration should take different conditions into account. This will help the sensor stay accurate in various environments.

Functional Testing Procedures

Functional testing checks how well the sensor works in real-world conditions, beyond just calibration. This type of testing checks things like response time, range, and sensitivity. It makes sure the device can adjust properly to changes in wind speed.

To do functional testing, expose the sensor to winds of different speeds and directions. Monitor how it reacts. Testing consistency in changing conditions makes sure the device gives reliable data over time.

Also, look at the sensor for any signs of wear or damage. Fix these problems fast to keep it working well.

Field Testing Wind Speed Sensors

Field testing helps us adjust and check how things work. It shows how the sensor works in the real world. This process usually means using the device for a long time. We analyze how reliable it is under real conditions.

When testing in the field, consider factors like the weather. Also, think about nearby buildings that might change how the wind flows. Make sure the equipment works well with data logging systems.

Check data from field tests often. Compare it with records from trusted sources, like local weather stations. This helps ensure accuracy.

Using best practices like these helps keep wind speed sensors working well. They give precise measurements that are important for many industries.

Maintenance and Troubleshooting for Wind Speed Sensors

Taking care of wind speed sensors is important for their long-term reliability and performance. It should be done with regular testing. Check the sensor often for wear, rust, or damage.

Clean it as needed to stop debris from building up and affecting its function. Make sure moving parts are well-lubricated for smooth rotation. Replace any worn components to keep accuracy.

When problems come up during testing or operation, good troubleshooting can help find and fix the issue. Check the sensor’s manual or the manufacturer’s instructions for help. If you need more help, contact technical support. Fixing problems quickly can help prevent malfunctions and keep sensor performance steady.

Conclusion:

In conclusion, it is important to test and maintain wind speed sensors. This helps keep them accurate and reliable for many uses. Key elements like calibration, functional testing, field testing, maintenance, and troubleshooting work together to ensure good sensor testing.

By following best practices and keeping a regular testing routine, you can make sure these sensors provide accurate data. This data is important for making informed decisions. Spending time and resources on good maintenance and testing can help avoid expensive mistakes and delays.