ultrasonic waterproof sensor

Ultrasonic sensors use sound waves to detect the position, distance, or movement of objects. Experts use them in many fields, like weather, industry, cars, and healthcare. However, like all technology, these sensors have some downsides. The main drawbacks of ultrasonic sensors are listed below:

1. **Susceptibility to Environmental Factors**

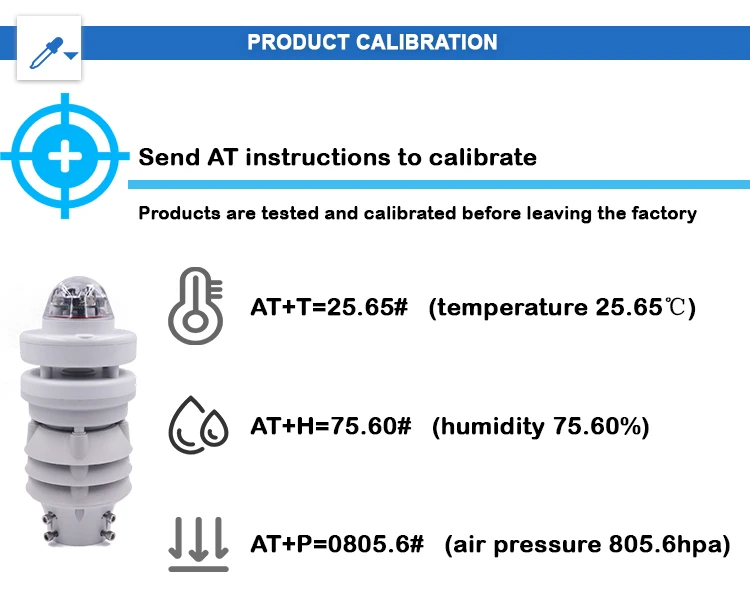

– **Temperature and Humidity:** Ultrasonic sensors can work less well when temperature and humidity change. This can reduce measurement accuracy.

– **Medium Variability:** The speed of ultrasonic waves varies in different materials. Changes in the medium, such as the type of gas or pressure, can affect measurement results.

2. **Sensitivity to Surface Roughness**

Rough surfaces can scatter or weaken the reflected ultrasonic waves. This results in less accurate measurements.

3. **Ranging Blind Spot**

Since the same transducer sends and receives waves, it needs a short time to switch. Because of this, at very close distances, the system might not catch the returning waves in time. This creates a blind spot in measurements.

4. **Beam Diffusion and Directionality**

Ultrasonic sensors have a set beam angle. This affects how well they measure orientation. They can only provide an estimated distance to objects. The spread of the beam can also cause more measurement errors.

5. **Triangulation Errors**

In some cases, ultrasonic waves do not move in straight lines. They can bend or scatter. This can lead to errors in triangulation measurements.

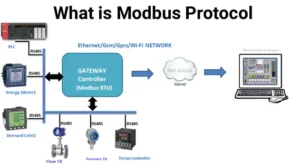

6. **Interference Sensitivity**

Ultrasonic sensors can be affected by their surroundings while they are in use. Mechanical vibrations and electromagnetic noise can cause problems for them. These disturbances can hide or alter the ultrasonic signal, which lowers accuracy.

7. **Measurement Speed Limitation**

Ultrasonic sensors are slower than laser or millimeter-wave systems. This means they are not good for tasks that need quick, real-time measurements.

8. **Directional Constraints**

Ultrasonic sensors send and receive signals in thin beams. This makes it hard for them to detect objects in some directions. Objects outside this narrow range may not be seen.

9. **Multipath Effects**

In places with many reflective surfaces, ultrasonic signals can bounce in different ways. This causes complex wave reflections that can affect sensor accuracy.

10. **Power Consumption**

The energy needed to send and receive ultrasonic signals can be quite high. This creates a challenge for battery-powered devices.

11. **Cost Considerations**

Ultrasonic sensors may cost more than other types of sensors. This is especially true for tasks that need long-range detection or high precision.

ultrasonic sensor specification

Measuring Range

Typical range: Usually from a few centimeters to a few meters. For example, some common ultrasonic sensors measure from 2 to 500 cm or from 5 to 800 cm. The exact range depends on the sensor’s design and use.

Accuracy: The measurement is usually accurate within a few millimeters to a few centimeters. High-precision ultrasonic sensors can reach an accuracy of ±1 to 2 mm. More general-purpose sensors may have an accuracy of ±5 to 10 mm.

Frequency

Operating frequency: Ultrasonic sensors work at frequencies higher than what humans can hear. They usually work in a range from 20 kHz to 200 kHz. Common frequencies are 40 kHz, 58 kHz, and 80 kHz.

The frequency you choose affects how well the sensor works. This includes its range, resolution, and how sensitive it is to different materials.

Bandwidth: The bandwidth of the sensor is the range of frequencies it can use. It helps the sensor send and receive ultrasonic signals. A wider bandwidth can give better resolution and a higher signal-to-noise ratio. However, it may also need more complex signal processing.

Resolution

Distance resolution:

This is the smallest change in distance that the sensor can detect. It is connected to how accurate the sensor is and the wavelength of the ultrasonic wave. Generally, the higher the frequency of the ultrasonic wave, the better the distance resolution. For example, a 40 kHz ultrasonic sensor may have a distance resolution of around 1 – 2 mm.

Angular resolution:

In some cases, like ultrasonic imaging or detecting objects, the sensor’s angular resolution is important. This term means how well the sensor can tell apart objects at different angles.

The angular resolution depends on two things. First, it is affected by the size and shape of the sensor’s transducer. Second, it is influenced by the beam pattern of the ultrasonic wave.

Power Supply

Current consumption: The sensor’s current use varies based on its operating mode and the complexity of the circuit. When the sensor sends and receives signals, it uses more current. In standby or low-power mode, it uses less. Typical current values range from a few milliamps to several hundred milliamps.

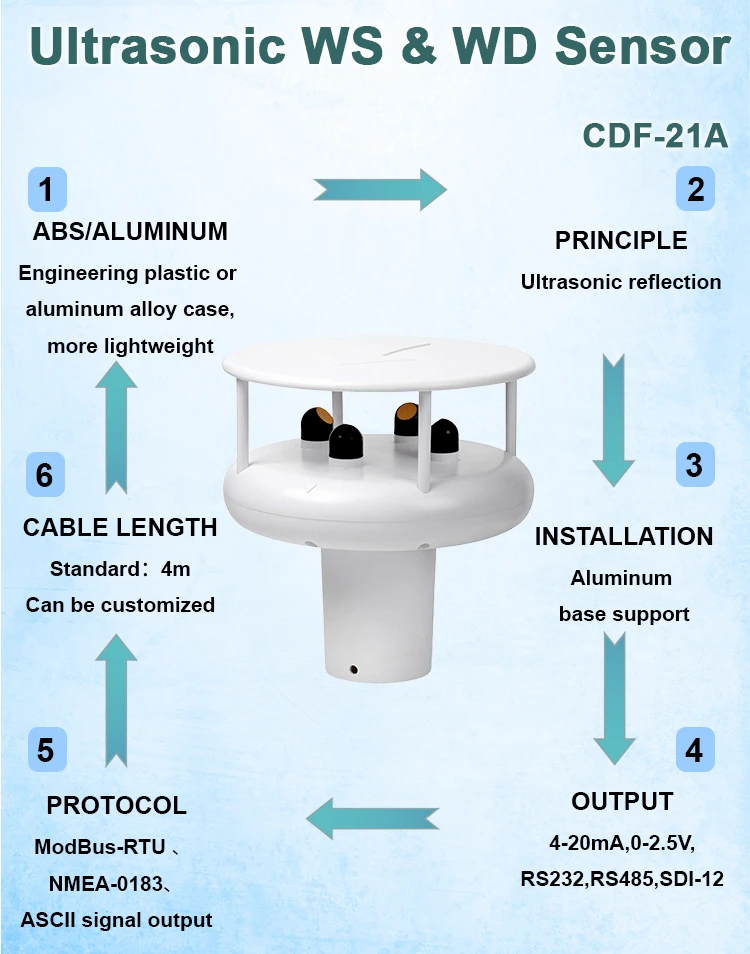

ultrasonic sensor specification Output Signal

Analog output: Many ultrasonic distance sensor provide an analog signal that shows the measured distance. The output can change in voltage or current.

It can be from 0 to 5 V, 0 to 10 V, or other standard ranges. This depends on the design of the sensor. You can easily connect this analog signal to microcontrollers or other circuits for more processing.

Some ultrasonic sensors can give digital output. This includes options like PWM, I²C, SPI, and UART. Digital output helps us communicate better with microcontrollers and other digital devices. It can also provide extra features like different measurement modes and sensor settings.

Physical Characteristics

Ultrasonic sensors come in different sizes and shapes based on their use. They can be small and compact for portable devices. They can also be larger for industrial use. Common shapes include cylinders, rectangles, and squares.

Material and construction: The housing of the ultrasonic sensor is often made from strong materials like plastic or metal. The transducer creates and receives ultrasonic waves. It is usually made of piezoelectric materials. The sensor’s design must withstand the conditions where it will be used, such as temperature changes, humidity, and vibrations.

Environmental Conditions

Operating temperature range: Ultrasonic sensors work best within a certain temperature range. This range can change based on the sensor’s parts and materials.

The normal operating temperature range is from -20°C to 60°C. Some sensors can work in more extreme conditions, from -40°C to 85°C. If the temperature goes outside this range, the sensor may not work well and could get damaged.

Humidity and waterproofing: The sensor must work well in different humidity levels. It should not lose performance. Some ultrasonic sensors can resist water or are waterproof. This feature is important for outdoor or wet areas.

Waterproof sensors have an IP code, such as IP67 or IP68. This code shows how well they can resist water and dust.

Here are the main features of ultrasonic sensors. Different brands and models may have special features. It is important to look at the product datasheet for correct information. This will help you pick the right ultrasonic sensor for your needs.

ultrasonic sensor specification Conclusion

Ultrasonic sensors are useful in many industries, but they do have some limits. They can be affected by their surroundings. They also have blind spots and can have trouble with direction.

Interference can affect their performance. They may have slower measurement speeds and often cost more.

To get the best results in real-world use, it is important to choose the right type of sensor. You should also set its settings based on the specific environment and needs. Planning carefully can help improve measurement accuracy and make the system more reliable.