Water Treatment Sensors Solution

Home » Water Treatment Solution

The development of Internet of Things applications in Water Treatment

In water treatment, we can check the status of different devices in real time with IoT sensors.

Water quality sensors can be set up in different ways. They help measure the important parts of water treatment.

Here are some water quality parameters: pH value, conductivity dissolved oxygen, COD, ORP, and total phosphorus.

Real-time data

The Internet of Things can collect a lot of data quickly. It does this by using sensors. These sensors include water quality sensors. They measure pH, dissolved oxygen, and turbidity.

It also uses flow sensors and pressure sensors. These are placed in water treatment systems and various monitoring sites.

Remote operation and control

The Internet of Things allows many water quality sensors to work at the same time. This gives a full picture of water quality. Different sensors can show water quality in different ways.

Monitoring factors such as dissolved oxygen, chemical oxygen demand (COD), ammonia nitrogen, and total phosphorus can indicate water pollution levels.

This information helps us learn about eutrophication. It also supports the creation of specific water treatment plans.

Multi-parameter integrated monitoring

The Internet of Things allows many water quality sensors to work at the same time. This helps check water quality in many ways. Different sensors can show water quality in many ways.

Monitoring factors such as dissolved oxygen, chemical oxygen demand (COD), ammonia nitrogen, and total phosphorus can indicate water pollution levels.

This information helps us learn about eutrophication and other problems. It also helps us create plans for treating water.

The application of sensors in Water Treatment Solution

PH Sensor

Function: It is important to check the pH level of the water. It helps us assess how stable and corrosive the water quality is.

In making tap water, it is important to keep the pH level safe for drinking. In sewage treatment, it helps maintain the best pH range for biological processes. This improves the results of the treatment.

DO Sensor

Function: It is important to measure the dissolved oxygen level in water. It shows how well water can clean itself. It also shows how healthy it is for aquatic life. In aquaculture, it provides farmers with a scientific way to feed and manage their fish.

Turbidity Sensor

Function: Water turbidity is measured by how much light is blocked or absorbed by particles in the water.

It helps track changes in the turbidity of incoming water. This allows for quick changes in early treatment steps, such as coagulation and sedimentation.

We monitor the water coming from a sewage treatment plant. We check that its turbidity meets the required standards.

ORP sensor

The REDOX potential sensor checks the balance of oxidizing and reducing substances in water. It shows how well disinfectants work in treating and disinfecting water.

In the biological treatment of sewage, operators can control the aeration rate. This helps make microbial degradation more efficient. It is important to monitor the levels of corrosive ions in industrial water. This stops damage to equipment.

Submersible Liquid Level Transmitter

Function: It is often used to check water levels in natural places like reservoirs, lakes, and rivers. It is also used to check liquid levels in clear pools and sewage ponds. This helps urban water supply systems. It provides data for flood control, drought relief, and managing water resources.

Rain Sensor

Function: The amount of rainfall has a significant effect on the quality and quantity of incoming water. Rainfall sensors can be set up close to the sewage treatment plant. This helps gather rainfall information ahead of time.

When rain is expected, the wastewater treatment plant can estimate how much water will come in. They use past data and real-time information from rainfall sensors.

TDS Sensor

Function:TDS (Total Dissolved Solids) sensors serve the function of detecting the TDS value of raw water. This detection is important because it allows for a quick assessment of the basic qualities of a water source.

Dissolved CO2 Sensor

In water, carbon dioxide and oxygen are mixed together. This connection takes up space. The amount of dissolved oxygen in water goes down. This causes a decrease in the amount of dissolved oxygen that can be held in water.

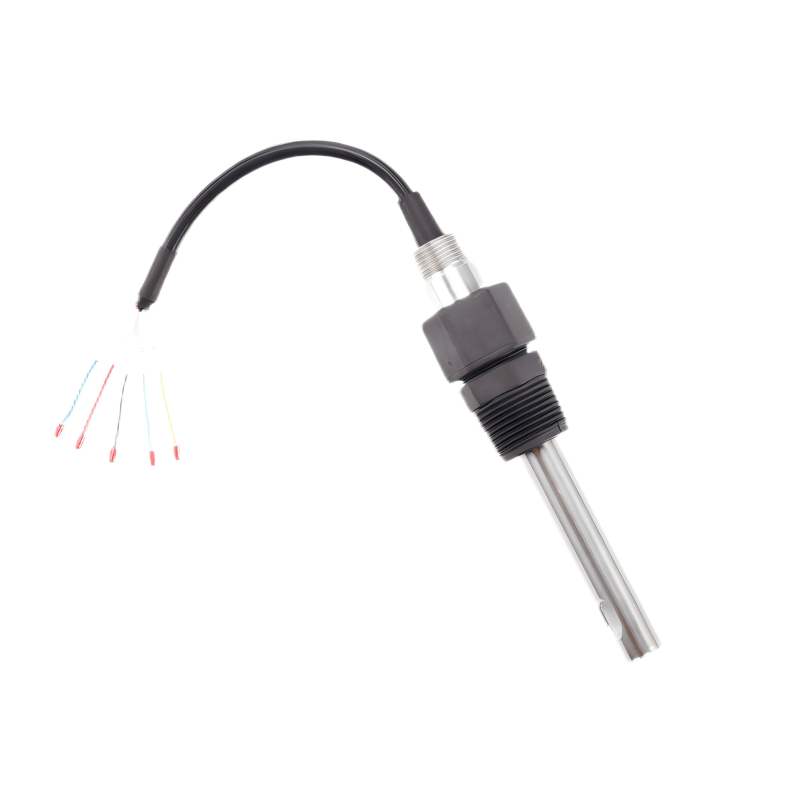

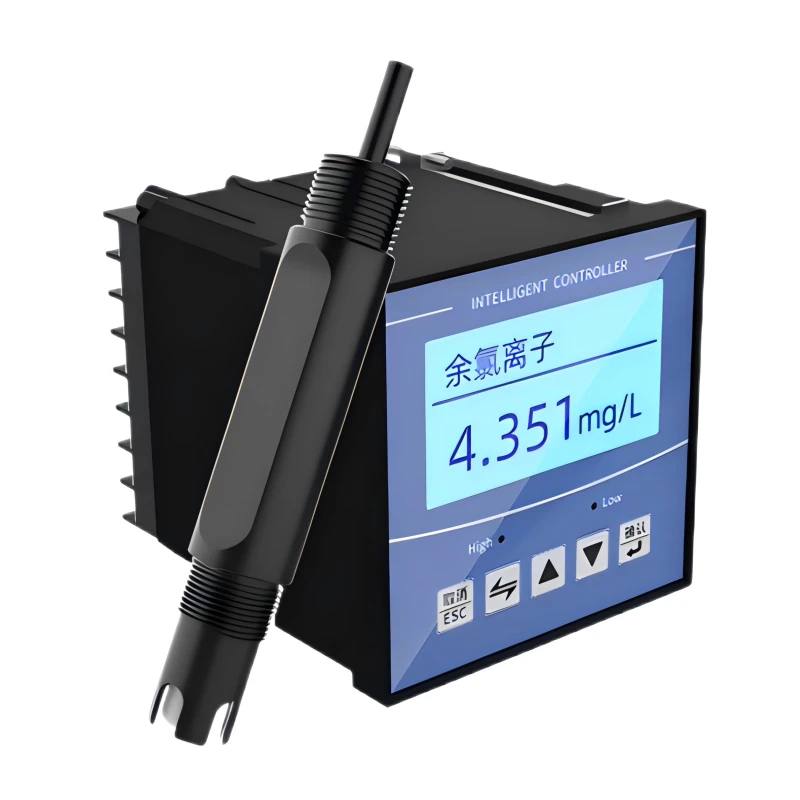

Residual chlorine sensor

Function: In the industrial water system, the residual chlorine sensor can monitor the chlorine levels in real-time. It helps stop the growth of microbes and the buildup of biofilm. This stops problems like blockages in pipelines, rust, and other issues.

This helps make the equipment last longer. It also ensures that the whole system works reliably and steadily.

Suspended Matter Sensor

In the first stage of water treatment, a sensor checks how much dirt is in the raw water. This sensor is called the total suspended matter sensor. This allows for a quick assessment of how polluted the raw water is.

If the total suspended matter in raw water is too high, it may show that the water is polluted. This pollution can come from dirt, organic matter, tiny living things, and other harmful materials. This information helps you choose the best water treatment method. It also helps to find out how strong the treatment should be.

Water Treatment Solution Customer Case

Background:

Monitoring and maintaining the quality of reservoir water.

Water Treatment Solution equipment:

Many water quality monitoring positions are set up in the reservoir. Online sensors are installed to track important factors. These factors include water temperature, pH value, dissolved oxygen, turbidity, and conductivity sensors. The sensors provide real-time data on these parameters.

In addition to online monitoring, it is important to do regular lab tests of the reservoir water. This means checking the levels of heavy metals in the water. It also looks at the types and amounts of organic substances and microbial factors.

Results:

The treated reclaimed water is pumped back into the aquifer through a series of injection Wells. This measure water stops seawater from coming back, raises the groundwater level, and improves the quality of groundwater.

Background:

Fresh water resources in the region are extremely scarce. To solve the problem of water shortage, many efforts have been made to develop seawater desalination technology. This technology aims to turn seawater into fresh water for homes and farms.

Water Treatment Solution equipment:

Dissolved oxygen and ORP are key factors for managing microbial growth in cooling water systems. The dissolved oxygen sensor checks how much oxygen is in the water. The ORP sensor shows the REDOX status of the water.

When the dissolved oxygen level in water is right and ORP is in the right range, it helps stop the growth of anaerobic bacteria.

If the dissolved oxygen is too low or the ORP is not normal, it can lead to microbial growth and biofilm.

Results:

Water is moved to fields using modern irrigation systems. This helps support efficient farming. Desalinated sea water is now used for irrigation. This has turned the empty desert into a useful farming area.

Farmers grow a variety of crops. These include both vegetables and fruits. This has greatly improved how much food Israel can produce on its own and how well it farms.

Background:

The original treatment process at the sewage treatment plant struggles to meet strict discharge standards and the need for clean water. The original sewage treatment plant mainly uses the old activated sludge process. This method does not work well to remove organic matter and nutrients, such as nitrogen and phosphorus, from sewage.

Weather station equipment:

A variety of sensors are placed at the inlet. These include turbidity sensors, chemical oxygen demand (COD) sensors, and ammonia nitrogen sensors. The turbidity sensor checks the clarity of the incoming water in real time.

When the influent turbidity exceeds 300 NTU, the control system adjusts the coagulant dosage. This change happens on its own during the pretreatment stage.

COD sensors help detect the organic content in influent water. Their data helps us predict how hard wastewater treatment will be in advance. The data from the ammonia nitrogen sensor helps control the denitrification process during biological treatment.

Results:

After the upgrade, the sewage treatment plant can now handle 150,000 cubic meters per day. This is an increase from the original 100,000 cubic meters. The quality of the treated water now meets the national first-class A standard.

LEAVE A MESSAGE

Just tell us your requirements, we can do more than you can imagine.

Welcome to Hunan CODA Electronic Technology Co., LTD

- Building S5, Oakes Plaza, Changsha, Hunan

- Monday to Friday: 9:00 a.m. to 20:00 p.m

- (+86)17775769236

- [email protected]