What Type of Sensor is Used to Measure the Water Level in a Tank?

Did you know that more than 4 billion people have serious water shortages? This includes about two-thirds of all people in the world. They experience these shortages for at least one month each year.

About 70% of the world’s water is used for farming. Industries use just under 20%, while households use about 12%.

These statistics show that water is a vital resource for supporting economies around the world. Therefore, efficient water management is crucial to mitigate water scarcity issues.

Industries and homes that need a lot of water often use storage tanks. This helps them have constant access to water. This is where water tank level sensors play a pivotal role.

These sensors help use water wisely. They display water levels in real-time. And they also alert you when tanks are low or full.

They are changing how water is managed for both industries and homes. This article looks at important uses, features, installation tips, and future trends of water tank level sensors. It aims to help you understand their value better.

Exploring Water Tank Level Sensors

Key Applications for Water Tank Level Measurement

Water tank level sensors are used to check how much water is in storage tanks. But you may wonder—what specific purposes do they serve across various sectors? Let’s delve into some prominent applications where these sensors play a vital role.

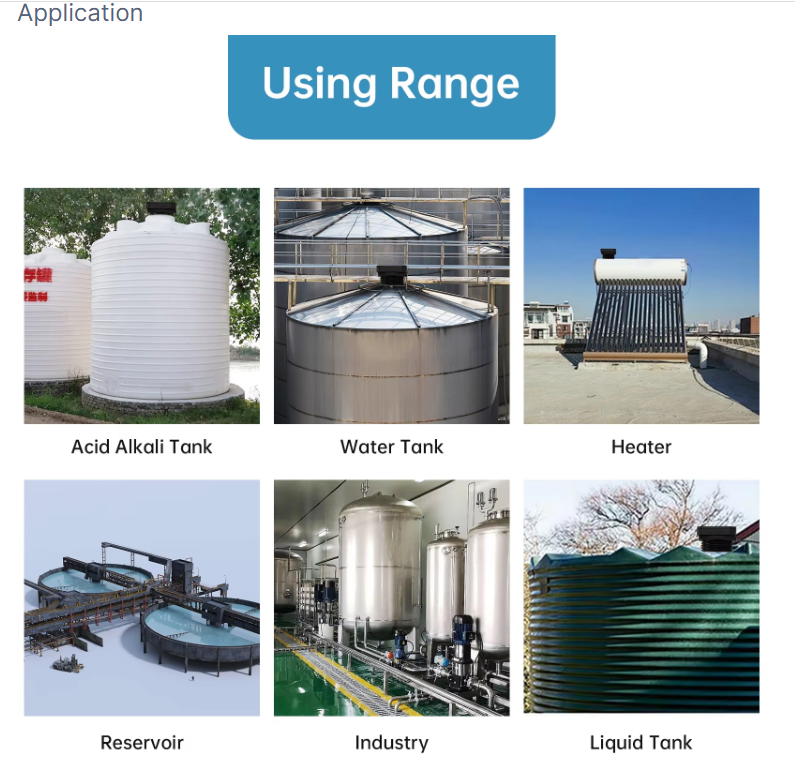

Industrial Water Management

Most industries need a steady water supply to operate well. To ensure a steady supply, industries often use large storage tanks with water level sensors. These sensors measure water levels accurately. This helps businesses use water better.

They alert when tanks are almost empty or completely full. This helps prevent waste from overflow. Industries like energy, textiles, automotive, and manufacturing depend on these systems for smooth operations.

Agricultural Irrigation Systems

The agriculture sector uses more than 70% of the world’s water, according to UNESCO. Measuring water levels is very important. Irrigation systems, fields, and reservoirs need a good water supply to work well.

Water tank level sensors help farmers plan irrigation better. They reduce water waste and protect crops from damage caused by uneven water levels.

Municipal Water Supply and Treatment

Cities use water tank level sensors to check and measure water levels. This helps with supply and treatment needs. These sensors help control flow, find leaks, and manage overall usage in different processes.

By keeping the right supply levels, they help prevent problems like overflow or underflow. This keeps the system working well and dependable.

Environmental Monitoring

It is important to keep track of water levels in reservoirs, lakes, rivers, ponds, and oceans. It helps us learn about the environment and guess what changes may happen in the future. Sensors give real-time data.

This helps researchers look at trends in water levels. They can respond quickly to problems like floods or droughts. This insight helps us take action quickly to prevent future crises.

Home and Residential Water Systems

On a domestic level, households consume around 12% of the global water supply. Many homes and apartment buildings use storage tanks. This helps ensure they have water, even without public sources. Installing a water tank level sensor helps residents check tank levels accurately.

When the water is too low or the tank is almost full, users can refill or turn off the pumps. This not only stops overflow or waste but also makes sure there is a steady supply for daily needs.

Key Features of Water Tank Level Sensors

There are many kinds of water tank level sensors. Each one has its own unique features. Some traits are common to all types, while others are specific to certain models.

This section lists the key features that water tank level sensors need. These features help ensure accurate and reliable results.

● **Accuracy and Precision**

The level of accuracy and precision varies among different types of water tank level sensors. Before you buy one, look for sensors that have an accuracy of ±1%FS or better. The lower this percentage is, the more accurate the sensor’s readings will be. This ensures precise water level readings with few errors.

● **Durability and Environmental Resistance**

Water tank level sensors often work in difficult environments. It is important for them to be durable and resistant to these conditions. A sensor with an Ingress Protection (IP) rating of IP68 is highly recommended. It offers complete protection against dust and water.

Environmental resistance also includes the temperature range where the sensor works. This range is important for its performance. A good-quality sensor should work in temperatures from -20℃ to +60℃. Sensors that handle a wider range can perform well in tough conditions.

● **Ease of Installation and Maintenance**

Easy installation and low-maintenance requirements are vital attributes in water tank level sensors. You can save time and money when these sensors are easy to remove or recalibrate for maintenance. Extra features like external recalibration, anti-corrosion materials, and strong stability help reduce maintenance and replacement over time.

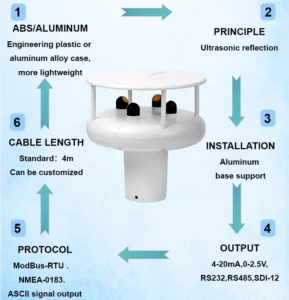

● **Signal Output and Compatibility**

The type of signal output from a water tank level sensor affects how well it works with monitoring systems. Many modern sensors can send signals such as 4-20mA, 0.5V, or RS485 (MODBUS-RTU). This makes it easy to connect with various automation or monitoring systems.

● **Cost-Effectiveness and Long-Term Reliability**

Price is an important factor when choosing a sensor. Some models cost more because they have advanced features. What really matters is how well the device works over time and how reliable it is.

Choose a strong sensor that lasts longer and works well. Don’t choose cheaper options that might cost you more later for repairs or replacements. Knowing what you need and focusing on long-term value will help you make a smart buying choice.

**Comparing Types of Water Tank Level Sensors**

Different water tank level sensors are made for specific tasks. They meet the different needs of users. To help buyers make a good choice, we look at the main types of sensors. We highlight their benefits, drawbacks, and the best manufacturers that offer quality products in each category.

Which Type of Sensor is Used to Measure Water Level in a Tank?

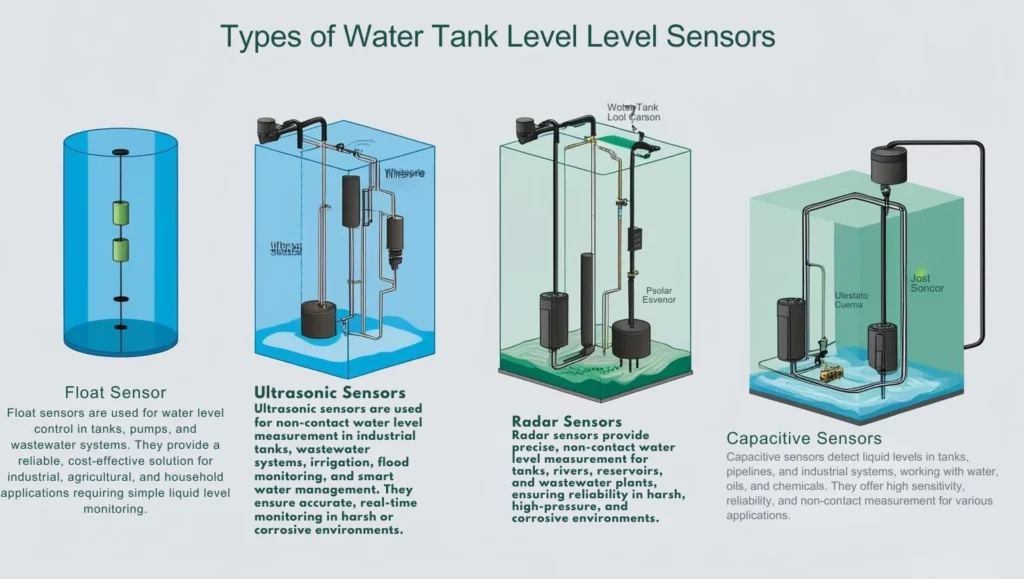

1. **Ultrasonic Level Sensors**

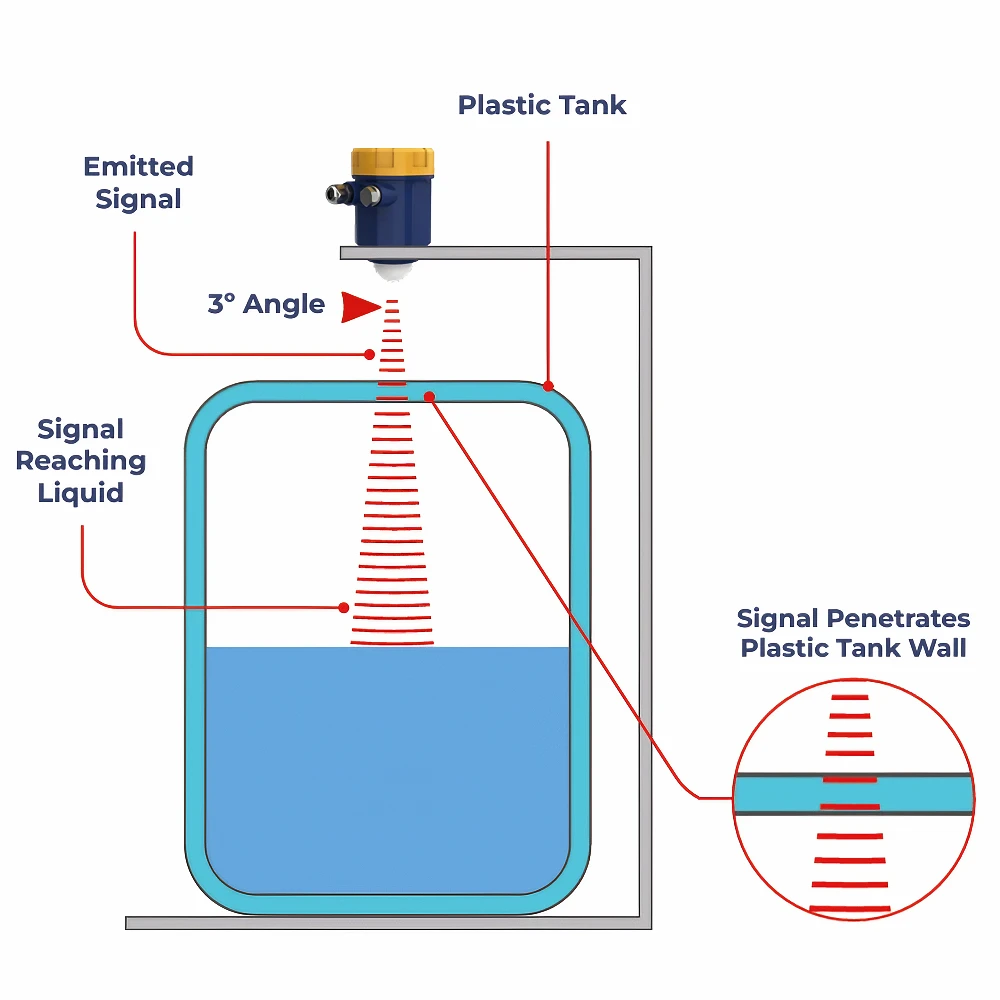

Ultrasonic sensors use sound waves to measure water levels. These sensors send out ultrasound waves to the water’s surface. The waves then bounce back and are detected by the sensor. By measuring how long it takes for the waves to come back, we can find the water level accurately.

**Advantages**

As non-contact devices, ultrasonic sensors offer several benefits. They can work well in dark conditions. They are not affected by the color or clarity of the liquid. These sensors provide accurate measurements, even in tough conditions like dust, dirt, or high humidity.

**Limitations**

Ultrasonic sensors use sound waves to work. They cannot operate in a vacuum because sound cannot travel there. Additionally, as non-contact devices, they are unsuitable for underwater use.

**Example**

The Ultrasonic Liquid Level Transmitter from Coda Sensor is a well-known product in the market. It has features such as high accuracy (0.5%-1%) and can measure distances up to 30 meters. It is easy to install. This makes it a great choice for a no-contact ultrasonic sensor.

2. **Pressure Transducer Level Sensors**

These sensors measure water levels by using the pressure from the liquid in a tank. For accurate readings, they must be installed at the bottom of the tank. Once calibrated, these sensors check the hydrostatic pressure to find the liquid level accurately.

**Accuracy and Stability**

Pressure transducers provide high accuracy of ±1%. They also have reliable stability over a long time. However, their readings can be affected by things like changes in liquid density, air bubbles, or temperature changes.

**Operating Environments and Media**

These sensors work well in temperatures from -20°C to +70°C. They are effective for both fresh water and wastewater uses.

3. **Capacitance Level Sensors**

Capacitance sensors measure water levels. They work by detecting changes in capacitance caused by the height of the liquid. They have a detection electrode.

It measures the capacitance between the sensor and the liquid. Changes in capacitance show changes in the liquid level.

**Application Versatility**

Capacitance sensors are flexible. They can measure levels in different types of liquids. Each liquid has its own dielectric constant. They are widely utilized in industries such as chemical processing, food production, and oil measurement.

**Installation and Calibration**

To work well, place these sensors where tank walls or sediment do not get in the way. Placing the sensor at the center of the tank often ensures more accurate results.

4. **Float Switch Level Sensors**

Float switch sensors work simply. They float on the liquid surface and move up or down as the liquid level changes.

This movement activates a switch. The switch sends signals to the control system. It shows whether the liquid level is going up or down.

**Reliability and Maintenance**

Float switches are very reliable because they have a simple design and few complex parts. However, to ensure consistent accuracy, frequent maintenance and inspections are needed.

**Best Applications**

Float switch sensors are cheap and easy to use. They are good for homes and businesses. And they are great for water storage tanks and wastewater systems.

They can connect to an on/off switch. This helps automate tasks, like shutting off valves when a certain water level is reached.

**How to Select the Right Sensor for Your Needs**

Choosing the right sensor depends on what you need. It’s important to find a balance between cost and functionality. Pick a sensor that has all the features you want and fits your budget.

Avoid simple models that do not meet your needs. To evaluate your operational environment, consider your accuracy needs and desired features. This will help you make a smart choice and get the most from your investment.

Choosing the right sensor to measure water levels in a tank needs careful evaluation of different factors. Here is a guide to help you with the selection process.

Factors to Consider:

– Liquid type, tank size, and environmental conditions: Not all sensors work with different types of liquids. Ultrasonic level sensors and pressure transducer sensors are designed for measuring water.

Capacitance and float switch sensors are flexible and can work with different liquids. Each sensor has specific ranges and adaptations for different environments. It is important to check the manufacturer’s guidelines to make the right choice.

Evaluating Accuracy and Reliability Requirements:

Accuracy needs change depending on how the sensors are used. Industrial applications that need exact water level readings require high-accuracy sensors. However, these sensors often cost more. For home use, simpler sensors with ±1%FS accuracy are often good enough and cost-effective.

Analyzing Installation and Maintenance Needs:

Easy installation is important to prevent problems during setup or removal. All sensors wear out over time. You can make them last longer by installing them correctly and keeping up with regular maintenance. This helps ensure they perform consistently.

Considering Cost and Long-Term Value:

Cost is important, but we should also consider a sensor’s durability. Its ability to provide accurate results over time is key. A higher price may show better materials and features. These improvements can increase reliability, making it a good investment.

Coda Sensor’s Support and Expertise:

Buying guidance can greatly help in finding the right solution. Coda Sensor has over ten years of experience in making sensors. We provide customer support and advice to help you find the right sensors for your needs, without any hassle.

Installation and Maintenance Best Practices:

To ensure water tank level sensors work well, you need to install and maintain them properly. Here are some important practices to follow:

Proper Sensor Placement and Mounting:

Different sensors have different ways to be installed. For example, ultrasonic sensors do not touch the liquid surface. In contrast, float switch sensors sit on the liquid itself.

Pressure transducers and capacitance sensors are immersed in the liquid. Following the instructions in the installation guide helps with the best placement and performance.

Cable Management and Signal Integrity:

Effective cable management is crucial for a sensor’s operational efficiency. Use insulated cables that are secured with ties. Leave some space for slight movement because of temperature changes. Ties that are too tight can strain wires or cause damage.

Regular Calibration and Cleaning:

Routine calibration keeps sensors accurate. Regular cleaning helps them last longer. These preventive measures lower replacement costs over time and help keep things running well.

Troubleshooting Common Issues:

Each type of sensor has its own challenges. General problems like bad calibration can cause wrong readings. Issues like interference often happen in ultrasonic sensors and can distort data. Many of these problems can be fixed with simple cleaning or by following maintenance instructions.

Future Trends in Water Level Sensing Technology

As the world embraces digital technology and artificial intelligence, water level sensing technology is also changing to keep up. Here are some key trends that are shaping the future of this technology.

★ Integration with IoT and smart systems

The Internet of Things (IoT) is a network of connected devices. These devices talk to each other and to cloud platforms to share data.

In water level sensing, these sensors connect to smart monitoring systems. This lets data be sent to cloud platforms in real time. This helps with analysis, reporting, and decision-making.

★ Advancements in sensor technology and materials

Companies in this field are working on water level sensors. They want these sensors to be smaller, lighter, and more accurate. They also aim to increase their range.

Innovations include using anti-corrosive and waterproof materials. These materials make sure they are strong and dependable. They help lower problems and ensure accurate measurements over time.

★ Increased focus on remote monitoring and data analytics

By using water level sensors with IoT systems, users can monitor levels from a distance. The data from these sensors can be accessed in real time. It can be analyzed with advanced tools to predict trends and improve water use. This allows for smarter, more efficient water resource management.