Level Sensor Devices vs. Traditional Methods: Which Offers Greater Accuracy and Efficiency?

Accurate level measurement is very important in many industries. This includes processing chemicals, making food, and working with oil and gas. Good level sensor monitoring helps operations run well. It makes product quality better and lowers costs.

In the past, industries used old methods to measure levels. These included float systems, dyes, and mechanical gauges. New technology has brought in level sensor devices. These devices are a better and more efficient choice.

While traditional methods have worked well, they have some clear limits. These include needing physical work, being likely to have mistakes, and not giving real-time data. Level sensor devices use advanced technology to give clear and accurate measurements. They work well even in tough environments.

Traditional Level Measurement Methods

Several conventional techniques are still in use for level measurement, such as:

**Float Gauges:**

– *How It Works:* Float gauges use a ball or rod that floats. This ball or rod moves up and down. It shows how much liquid is inside.

– *Advantages:* They are easy to use, cheap, and simple to set up.

– *Limitations:* Mechanical parts can break down. Their accuracy is limited. These gauges can also sense changes in fluid thickness and temperature.

– *Applications:* You can often find these in tanks and storage containers for basic checks.

**Dye Markers:**

– *How It Works:* Liquid levels can be seen with color indicators.

– *Advantages:* Installing these systems is simple. They are easy to set up and easy to read.

– *Limitations:* Accuracy is limited. Performance is affected by lighting and fluid color. They do not work well with some fluid types.

– *Applications:* Popular in food and beverage industries due to their simplicity.

**Mechanical Gauges:**

– *How It Works:* Mechanical systems show fluid levels using moving parts linked in the gauge mechanism.

– *Advantages:* Strong and dependable in difficult conditions.

– *Limitations:* These gauges will wear out as time goes on. They need regular checks and are not very precise.

– *Applications:* Commonly used outside or in tough places where strength is important.

Modern Level Sensor Devices

Level sensor devices use advanced technologies such as ultrasonic, radar, or capacitance systems. These technologies give more accurate level measurements.

**Ultrasonic Level Sensors**

– *How It Works:* Sound waves measure how far the sensor is from the liquid surface. This helps to find the levels.

– *Advantages:* Non-contact technology works well for both solids and liquids. It provides high accuracy.

– *Limitations:* Performance can be impacted by foam, temperature changes, dust, or moving objects.

– *Applications:* This works well for tanks, silos, and hoppers in many industries.

**Radar Level Sensors**

– *How It Works:* Radio waves are sent out to measure the distance to the liquid surface. This helps to find the level.

– *Advantages:* Provides precise non-contact measurement, even through non-metallic tank walls.

– *Limitations:* Challenged by tank curvature, temperature shifts, or surface conditions like moisture.

– *Applications:* This is great for storage tanks and important for industrial processes, especially in chemical work.

**Capacitance Level Sensors**

– *How It Works:* Electrical fields sense changes in the fluid’s dielectric constant to find levels.

– *Advantages:* Reliable non-contact operation works well with many types of media.

– *Limitations:* “Needs calibration and may have problems in different temperature conditions.”

– *Applications:* Commonly used in industries such as pharmaceuticals, chemical production, and food processing.

Accuracy and Reliability: A Comparative Overview

**Accuracy Levels:**

Traditional measurement methods often have a range of accuracy. For float and dye systems, this range is from plus or minus 1% to plus or minus 5%.

For mechanical gauges, the range is from plus or minus 0.5% to plus or minus 1%. Level sensors work better than old methods. Ultrasonic and radar systems can reach accuracy levels of plus or minus 0.1%. Capacitance sensors can achieve an accuracy of up to ±0.2%.

**Case Study Highlights:**

– **Petrochemical Plant:** Switching from float gauges to ultrasonic sensors in storage tanks cut measurement errors by up to 90%.

– **Food Processing Facility:** Using radar sensors in batch reactors made them more efficient. They let users adjust levels in real-time and cut down on material waste.

Reliability and Maintenance Comparison

Traditional methods, like float gauges and mechanical systems, often need regular maintenance or recalibration. This is because they can wear out or be affected by their surroundings. Modern level sensors work with little help for long periods. This makes things more reliable and cuts down on maintenance work.

Efficiency in Data Collection and Analysis

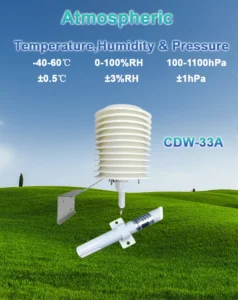

Level sensor technology makes it easier to collect data in real time. It also provides important insights into level changes.

Real-Time Monitoring:

These sensors send data to monitoring systems all the time. This helps make quick adjustments and better control.

Advanced Data Processing:

Modern sensors work well with IoT platforms. This allows for strong analytics and helps with predictive maintenance.

IoT Connectivity:

Connecting with IoT systems makes it easy to monitor and manage. This makes operations run much more efficiently.

Cost Analysis:

Balancing Initial Investment with Long-Term Gains

A cost analysis shows that level sensors need a bigger initial investment. They can save a lot of money in the long run.

Initial Expenditure:

Level sensors often come with a higher initial cost compared to traditional techniques.

Reduced Operational Costs:

With low maintenance needs and less downtime, costs will go down over time.

Maintenance Savings:

Traditional methods need regular servicing and calibration. This leads to higher ongoing costs.

Practical Insights:

A study of a chemical plant showed that using level sensors paid off in 18 months. This happened because there was less time wasted and the process worked better.

Environmental Benefits and Future Trends

Level sensor technology helps the environment and opens doors for new innovations.

Eco-Friendly Advantages:

These devices reduce the need for manual work. They reduce emissions and make the workplace safer.

Technological Advancements:

Recent advances in AI and machine learning are making sensors more accurate. They are also improving automation skills.

Future Innovations:

New technologies, such as nanotechnology and smaller sensors, will make these systems better. They will be faster, more precise, and less expensive.

Shaping the Future of Level Measurement

In conclusion, traditional methods have worked well in the past. However, level sensor devices are a better choice for accurate and efficient level measurement. Their high accuracy and reliability make them very useful for modern industry. They provide real-time data that is essential.

Industries should use technology for level sensors. This will help them do better and use new ideas. The development of level measurement comes from new sensor systems. These systems provide precision and reliability for the future.