Description

CDL-13B Ultrasonic Liquid Level Transmitter

The CDL-13B Ultrasonic Liquid Level Transmitter, which is a kind of material level measuring instrument that features non-contact operation, high reliability, high cost performance, and is easy to install and maintain. It doesn’t need to contact the medium yet can meet the requirements of most material level measurements.

It fires a pulse and the interval between sending the pulse and receiving it is proportional to the distance from the antenna to the surface of the measured medium. Thus, we can calculate the distance from the antenna to the surface of the measured medium. The product can cooperate with the CDH-TM data logger or a general recording instrument for use.

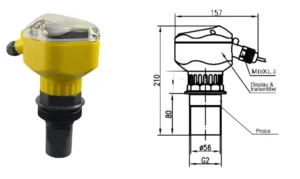

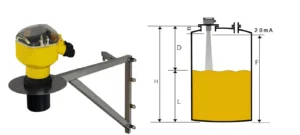

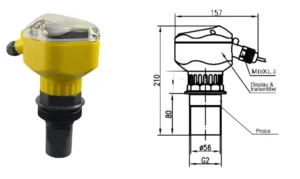

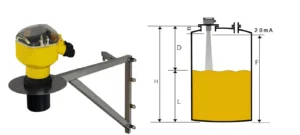

Dimnsion & Mounting

ultrasonic level sensors details show

Application

Water treatment:

◉In sewage treatment plants, ultrasonic level sensors play an important role. When measuring the liquid level in sewage tanks like grid tanks, sand – settling tanks, aeration tanks, and secondary – settling tanks, we install the sensor above the pool top. It determines the liquid – level height by sending and receiving ultrasonic pulses. For instance, in aeration tanks, despite sewage surface foam, floating objects, and water flow, ultrasonic level sensors can penetrate these interferences to measure the level accurately.

Chemical industry:

◉In the chemical industry, ultrasonic level sensors monitor dangerous chemical storage tanks. For corrosive, toxic, or explosive chemicals, non – contact ultrasonic measurement ensures safe operation by avoiding direct sensor – chemical contact.

Warehousing and logistics industry:

◉In liquid product storage areas such as oil tank zones and chemical liquid warehouses, ultrasonic level sensors monitor the liquid levels of different storage tanks. For example, in an oil tank area, installing these sensors on each tank top allows real – time monitoring of the oil product liquid level.

Ultrasonic Liquid Level News

Aquaculture Monitoring Solution

What is an Ultrasonic Level Sensor?