water level indicator hydroponics

Introduction to Hydroponics and Water Level Monitoring

Hydroponics monitoring helps grow plants without soil. It provides plants with important nutrients through a water solution. In this system, keeping the right water levels is crucial for healthy plant growth and high productivity. This article looks at effective solutions and best practices for monitoring water levels in hydroponics systems.

The Importance of Monitoring Water Levels

Water is essential for any hydroponic system. It is important to check water levels often. This helps avoid under or overwatering.

Both can stress plants and affect how they absorb nutrients. Good management ensures that plants get enough water and nutrients.

It also stops water from building up, which can hurt root growth. Regular checks help farmers find problems early. This lets them act quickly for better plant growth.

Techniques for Monitoring Water Levels

Float Valve Systems

A widely used approach in hydroponic setups is the use of float valves. Technicians link these mechanisms to both the water reservoir and supply line. When the water level drops in the tank, the float valve opens. This lets water flow in until the target level is back.

Once it reaches the right level, the valve shuts off by itself. Float valves are a simple and effective way to keep water levels steady. This is especially helpful for larger systems that need less manual work.

Automated Water Level Sensors

Water is the key part of any hydroponic system. It is important to check water levels often. This helps prevent under or over watering. Both issues can stress plants and affect how they absorb nutrients.

Good management makes sure plants get enough water and nutrients. It also stops water from building up, which can harm roots. Keeping track of plants helps growers spot problems early. This way, they can take action quickly to help plants grow their best.

Factors to Consider When Monitoring Water Levels

1. Type of Hydroponic System

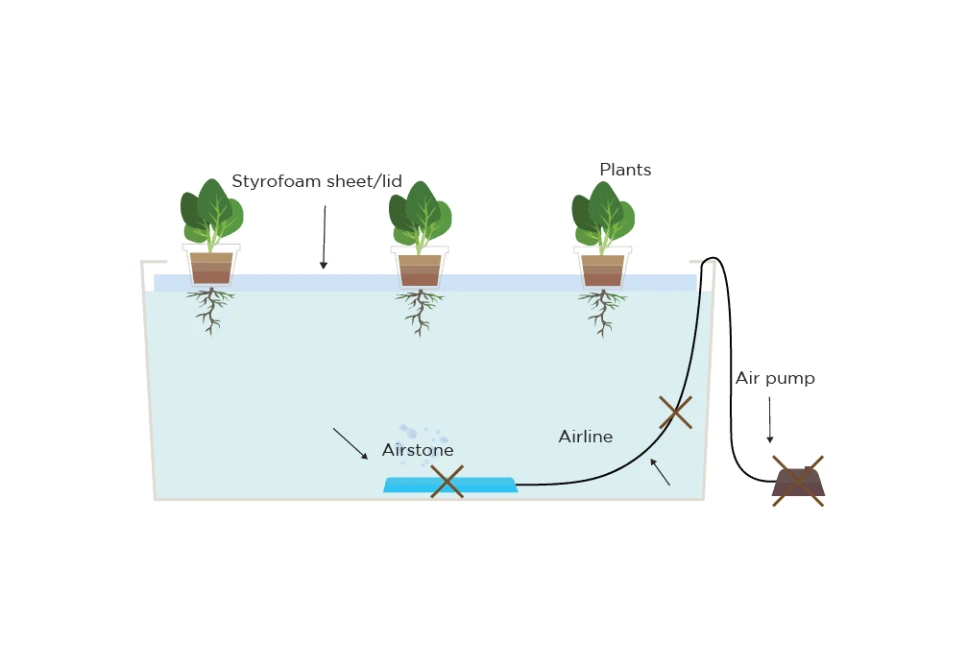

Different hydroponics monitoring systems need specific ways to check water levels. In deep water culture (DWC) systems, keeping the water level steady is important. The water should cover the roots but not completely submerge them.

On the other hand, nutrient film technique (NFT) systems use a steady flow of water. This makes it important to watch flow rates carefully. Knowing the specific needs of your water level indicator hydroponics system is key for good water level management.

2. Nutrient Solution Concentration

Monitoring water levels is not just about tracking how much water is present. It is also important to check the nutrient solution’s concentration. As water evaporates, the nutrient concentration goes up because the nutrients stay in the system.

Measuring electrical conductivity (EC) regularly helps keep the right nutrient balance. Technicians can then make adjustments. They can add fresh water to dilute or add more nutrients to get the right mix.

Best Practices for Water Level hydroponics monitoring

1. Regular Inspections

Check water levels and system conditions regularly to prevent problems. Experts suggest daily checks to ensure water levels stay stable. Look for any blockages, leaks, or maintenance issues that could affect water flow. Remember to measure and adjust the nutrient solution concentration as needed during these checks.

2. Calibration of Sensors

For growers using automated water level sensors, regular calibration is important. It helps ensure accuracy. Well-calibrated sensors provide reliable data.

This data helps make precise adjustments when needed. Always follow the calibration steps from the manufacturer. If you are unsure, ask a professional for help.

3. Backup Systems

To prepare for unexpected problems like power outages or equipment failures, get backup systems. Use extra float valves or backup batteries for your sensors. These safety measures lower risks and keep water levels steady during emergencies. This helps protect plant health and growth.

4. Data Analysis and Recordkeeping

Tracking water levels, temperature, and humidity can give useful insights. Over time, this record can reveal trends and improve water use and system performance. By looking at this data, growers can adjust water levels, improve nutrient mixes, and enhance their hydroponic systems.

conclusion

In summary, watching water levels is important in hydroponics. It helps plants grow strong and healthy. By using good methods, growers can keep water levels steady. This creates the best conditions for plants that do not use soil.

Hunan CODA Electronic Tech Co., Ltd provides many modern sensor solutions for OEM applications. These high-quality sensors improve environmental monitoring systems. They also add value to products by meeting different needs.

Hunan CODA Electronic Tech Co., Ltd has many clients both at home and abroad. They are ready to provide custom solutions for OEM sensor needs. If you have specific inquiries, feel free to reach out to us at CODA Sensors—we’re here to assist you.

Using advanced OEM sensor technologies lowers risks in managing environmental monitoring systems. It also helps use resources more efficiently.

Hunan CODA Electronic Tech Co., Ltd shows great expertise and clear operations. This gives customers helpful insights and mentorship. Working with us ensures you get high-quality solutions. It also helps you see how we drive innovation and support growth in the sensor industry.