How to Use a Water Level Sensor

In various industries and daily life scenarios, monitoring water levels accurately is crucial. water level detector sensor help manage water storage in tanks. They also prevent floods in drainage systems. Additionally, they ensure industrial processes work properly. However, to fully leverage their capabilities, it’s essential to understand how to use water level probe sensor effectively.

Types of Water Level Sensors and Their Basics

Before delving into the usage, it’s important to be familiar with the different types of water level sensors. One common type is the float – type water level sensor. It has a float that sits on the water’s surface. This mechanism links to the float. The mechanism changes the float’s up and down movement into an electrical or mechanical signal. As the water level goes up or down, the float moves with it. The sensor then gives an output that shows the current water level.

Another type is the ultrasonic water level probe sensor. This sensor works by emitting ultrasonic waves towards the water surface. When the waves hit the water, they reflect back to the sensor. The sensor measures how long it takes for waves to travel to the water surface and back. This helps it calculate the distance to the water level and find out the water level. Ultrasonic sensors do not touch the water. This makes them good for measuring corrosive or dirty liquids.

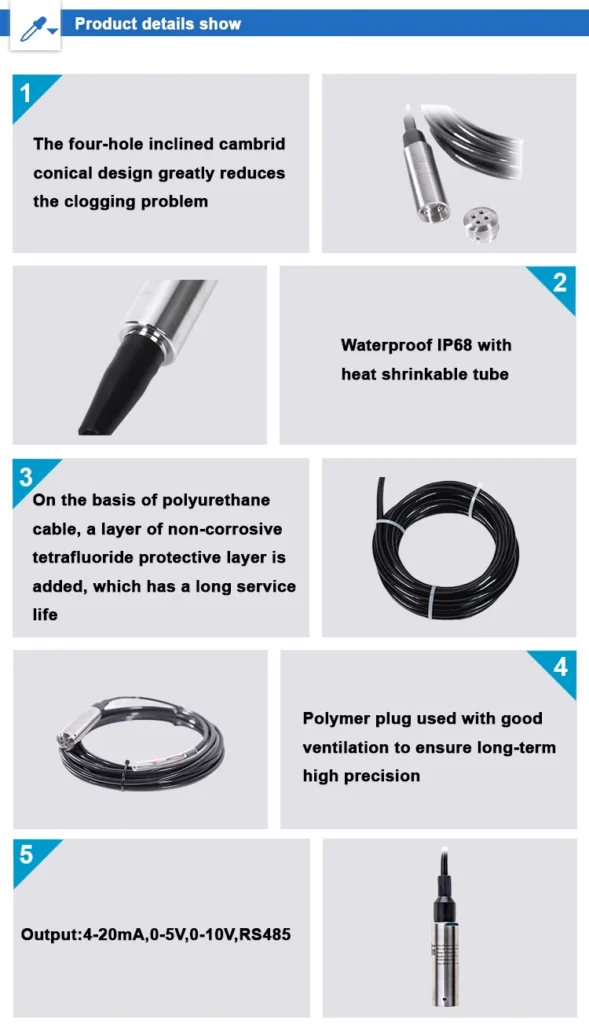

Pressure – based water level sensors are also widely used. These sensors measure the hydrostatic pressure exerted by the water column. The pressure increases as the water level rises. The sensor uses the idea that pressure increases with the depth of the liquid. It can change the measured pressure into a water level reading. Pressure – based sensors are often used in submerged applications, such as measuring the water level in wells or deep tanks.

Installation

Float – Type Sensors

For float – type water level detector sensor, the first step is to select an appropriate location in the water container. The location should be free from turbulence, debris, and any obstructions that could interfere with the movement of the float. Then, install the sensor according to the manufacturer’s instructions. Usually, this involves attaching the sensor to the side or top of the tank. Make sure the float can move freely up and down without getting stuck. Connect the sensor to the control unit or data acquisition system using the provided cables. Check the electrical connections to ensure they are secure and properly insulated.

Ultrasonic Sensors

When you install ultrasonic water level probe sensor, pick a spot at the top of the container or above the water. Mount the sensor to ensure it has a clear line of sight to the water surface without any obstacles in between. The distance between the sensor and the maximum water level should be within the measurable range of the sensor. Connect the sensor to a power source and the data – receiving device. Some ultrasonic sensors may require calibration before use. You can usually do this by entering the distance from the sensor to a reference point. This reference point could be the bottom of an empty tank.

Pressure – Based Sensors

For pressure-based water level sensors, if it is a submersible type, gently lower the sensor into the water. Do this until it reaches the desired depth. Make sure to protect the cable that connects the sensor to the surface. Avoid damaging it while you work. If you have a surface-mounted pressure sensor, install it on the side of the container. Make sure it measures the water pressure above it. Also, seal it well to prevent water leaks. Connect the sensor to the data-processing equipment. Then, set the sensor settings based on the application’s needs. This includes choosing the right unit of measurement, like meters or centimeters, and adjusting the calibration parameters.

Configuration and Calibration

After installation, most water level detector sensor need to be configured. This includes setting parameters such as the range of measurement, the unit of measurement, and any alarm thresholds. For example, if you use a water level sensor for a water tank, you can set an alarm. This alarm will go off when the water level drops below a certain point, like 20% of the tank’s capacity. It can also trigger if the water level rises above a safe point, like 90% of the tank’s capacity.

Calibration is also an important step to ensure the accuracy of the sensor. Different sensors have different calibration methods. Float-type sensors may need you to adjust the float’s position or the calibration mechanism. This helps match the actual water level. You can calibrate ultrasonic sensors by measuring the distance to a known object. This is done at a fixed distance. Then, you adjust the sensor’s settings based on this measurement. Pressure-based sensors often need calibration. You can use a known pressure source to do this. Alternatively, you can compare the readings with a reference measurement in a controlled environment. Regular calibration, usually at specified intervals recommended by the manufacturer, helps maintain the sensor’s accuracy over time.

Monitoring and Data Analysis

Once you install and configure the water level probe sensor, it starts continuously monitoring the water level. The sensor collects data that you can show on a local display. You can also send it to a remote monitoring system or save it in a data-logging device. In an industrial setting, operators can send water level data to a central control room. Operators can monitor the levels in real-time. They can take action if any problems occur.

Analyzing the data can provide valuable insights. By examining the historical water level data, you can spot trends. This includes seasonal changes in water use. You can also find unusual patterns that may show a problem, like a slow leak in a tank. Data analysis can also help optimize water management. In a water supply system, looking at the water level data in storage tanks can help plan the pumping schedule. This can save energy and ensure a steady water supply.

Maintenance

Regular maintenance is essential to keep the water level sensor functioning properly. For float – type water level detector sensor, check for any signs of wear and tear on the float and the connecting mechanism. Clean the float and the surrounding area to remove any debris or sediment that could affect its movement. Keep ultrasonic sensors clean to ensure accurate readings. Clean the sensor’s surface often. This will help remove dust, moisture, or other things that can block the ultrasonic waves.

For pressure-based sensors, especially submersible ones, check the cable for damage. Also, make sure to seal the sensor properly. If you use the sensor in a corrosive environment, consider using protective coatings or materials to extend its lifespan. Additionally, perform regular checks on the calibration of the sensor to ensure its accuracy. Replace any faulty components promptly according to the manufacturer’s guidelines.

Conclusion

Using a water level sensor effectively involves proper installation, accurate configuration and calibration, continuous monitoring, and regular maintenance. You can learn about different types of water level sensors. By following these steps, you can get reliable and accurate water level measurements. You can use these measurements for many purposes. A good water level sensor is important for homes, industries, and the environment. It helps ensure safety, efficiency, and proper resource management.