Troubleshooting Methods, Maintenance Technologies, and Installation Demands of Soil Moisture Sensors.

Introduction:

Soil moisture sensors are important tools. They measure how much moisture is in the soil. This greatly helps agriculture and environmental science. These sensors can encounter common issues necessitating prompt troubleshooting and maintenance. This article outlines the typical problems associated with soil moisture sensors, alongside effective maintenance techniques and installation requirements.

I. Common Problems:

1. Electrical issues:

Problems like failure to start, weak power connections, or damaged circuits can affect how sensors work. This can lead to inaccurate data.

2.Water accumulation:

Sensors in damp areas may collect water over time. This can cause wrong readings or affect performance.

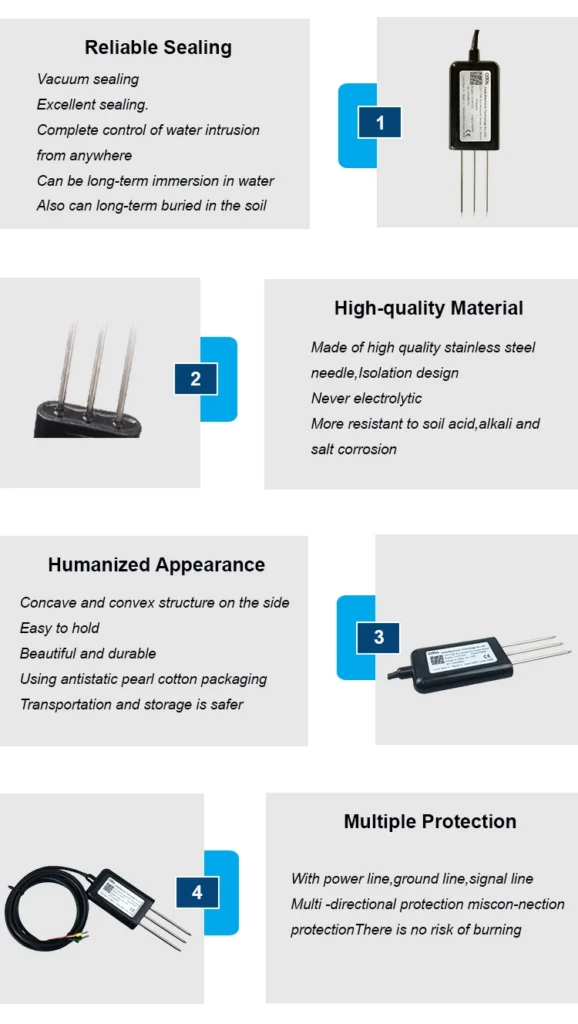

3. Physical damage:

Sensors can get damaged by crushing, impacts, or harsh conditions. This can lead to failures or mistakes in measurement.

II. Maintenance Techniques:

1. Check power and connections:

Begin troubleshooting electrical issues by verifying the sensor’s power supply and circuit connections. Ensure all connections are secure and wires remain intact.

2. Clean the sensor:

Gently wipe the sensor surface with a clean, damp cloth to eliminate moisture and dirt. Avoid using chemical solvents or excessive force to prevent sensor damage.

3.Replace damaged parts quickly.

This includes wires and circuit boards. Make sure the new parts meet the required specifications. Always follow the manufacturer’s repair guide.

III. Installation Requirements:

1. Regular calibration: The sensor’s accuracy is largely determined by its calibration status. Regularly calibrate according to the manufacturer’s guidelines for precise measurements.

2. Appropriate installation depth:

Proper sensor depth is key to accurate soil moisture measurement. This varies with crop types and soil characteristics, so ensure full insertion into the soil at the appropriate depth.

3. Waterproofing:

Given the damp environment, applying waterproof measures is crucial. Use waterproof connectors or sealant tape to shield the sensor and connections from moisture intrusion.

4. Ongoing maintenance:

Regular maintenance activities, such as cleaning, part replacement, and timely calibration, are essential for ensuring optimal sensor operation.

Conclusion:

Soil moisture sensors are integral to agriculture and environmental studies but face common operational issues. Effectively troubleshooting electrical problems, performing timely repairs, and adhering to installation protocols help maintain sensor functionality and measurement precision. Regular maintenance is crucial for fostering performance stability and reliability. Always consult the manufacturer’s repair guide and adhere to safety standards during maintenance activities.