pH Sensor Types and pH Electrode Choose

Choosing the right water quality sensors is important. This is especially true for pH sensors. They give accurate measurements. There are many types of pH sensors. Many people ask, “How do I choose the right pH sensor?” and “Where do I start?”

It is important to know the different types of pH sensors and what they do before buying one. This article will help you learn about these sensors and choose the right one.

Understanding pH Sensors:

A pH sensor is a key tool for measuring how acidic or basic liquids are. It provides pH values from 0 to 14. Many people use these sensors to check water quality. They help keep drinking water safe and treat wastewater.

People often show the ph scale measures how acidic measures with values ranges from 0 to 14. In this range of ph, lower values mean more acidity. Higher values mean more alkalinity.

A pH level of 7 is neutral. Values below 7 show acidic conditions. Lower numbers mean stronger acidity.

On the other hand, values above 7 show alkaline conditions. Higher numbers mean more alkalinity. In real life, people rarely see solutions with a pH of exactly 0 or 14.

Keeping the right pH levels is important for production. It helps ensure product quality. pH can affect key traits like appearance and taste.

The best pH range for drinking water is 6.5 to 8.5. This range is safe for people to use.

Researchers often use pH sensors to test water quality. They use this in farms, factories, and labs. This keeps liquids safe and helps balance chemicals.

Types of pH Sensors:

No matter what you are doing, it is important to keep the pH level just right. This is true for both acidic solutions and strong alkaline bases. Here are four types of pH sensors for liquid monitoring:

1. **Combination pH Sensors**:

These devices have two types of electrodes: a measuring electrode and a reference electrode. The reference electrode gives a stable baseline signal. The measuring electrode detects changes in pH levels.

2. **Differential pH Sensors**:

These sensors have three electrodes. One of them is a metal ground electrode. Their strong design helps keep the reference system clean. This makes them strong and dependable.

3. **Laboratory pH Sensors**:

Manufacturers make these sensors with a plastic case and a 12 mm glass shaft. They are useful for simple tasks. For example, they can check water quality in pools or watch the environment.

4. **Process pH Sensors**:

These sensors use advanced technology. They have a strong body with built-in connectors. They are ideal for constant use in industrial settings.

PH measurements make up more than 25% of quality checks in process industries. It is important to have pH sensors that are reliable and accurate. This helps make plants work better and keeps operations safe.

Our product range provides solutions for tough situations like unstable media, thick fluids, dangerous environments, and water treatment. Take a look at our water quality sensors and full system solutions to find what works best for you. If you have a specific use, we can suggest the best type of pH sensor for you.

Choosing the right type of pH sensor electrode is important for measuring different solutions accurately. Using the wrong electrode can lead to wrong readings and possible damage. This can increase project costs.

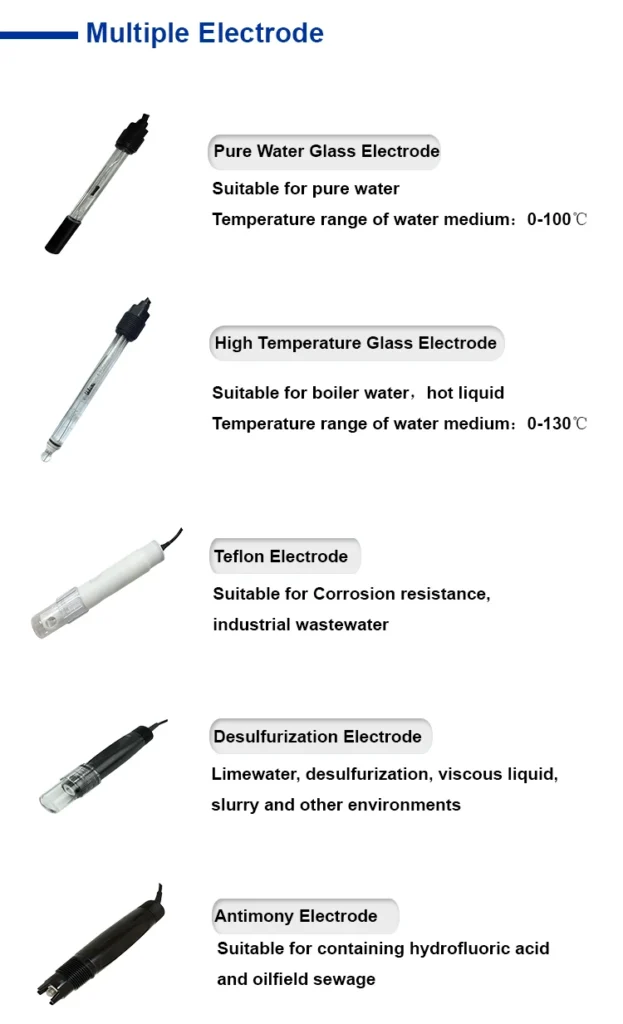

different types of ph sensors:

1. **Glass Electrode**:

This pH sensor type has a special glass membrane, a reference electrode, and a buffer solution. It offers high accuracy and a quick response. It also has little interference from pure water color and turbidity.

Engineers use it in many fields like bioengineering, pharmaceuticals, beer brewing, chemical processing, and electronics. This makes it great for places with corrosive materials.

2.**Combination Electrode**:

This combines the glass and reference electrodes with a temperature sensor that is built-in. It is great for regular lab tests and industrial monitoring. It is compact and easy to use.

3. **Desulfurization Electrode**:

This flat electrode has a gel design that requires no maintenance. It gives accurate measurements in high temperatures or high pH levels. Its easy-to-clean surface makes it great for measuring pH in mineral slurry and flue gas cleaning.

4. **PTFE Electrode**:

This electrode is made from polytetrafluoroethylene. It resists strong acids, bases, and alkalis well. Its protective ring helps make it more accurate. This makes it perfect for measuring pH in industrial wastewater and in very acidic or alkaline areas.

5. **Antimony Electrode**:

This electrode uses metallic antimony and has a thin oxide film. It reacts with hydrogen ions and hydroxide ions. It is great for very corrosive solutions, like those with hydrofluoric acid, because it resists corrosion well.

6. **Electroplating Electrode**:

This electrode has a dual-junction design. It has a longer reference diffusion path. This helps it last longer and makes it easier to care for in tough conditions. It is great for treating wastewater, electroplating wastewater, fermentation processes, and areas with high organic content.

Industries like chemical processing, wastewater management, beverage manufacturing, pharmaceuticals, energy production, and oil and gas often use ph meter. The type of pH sensor you choose depends on the needs of your application.

You can customize glass sensors by choosing the right diaphragm and reference system. ISFET sensors are better for places where glass might break or where there are high levels of organic solvents. You should use enamel sensors when you need stability for a long time and low maintenance.

Importance of pH Sensors:

n water pretreatment for manufacturing, pH sensors play a key role in quality control. They help clean the water before it is used in production.

This makes operations run better and boosts heating and cooling efficiency. It also helps meet water quality standards. Reliable monitoring provides benefits such as:

– Reduced water waste

– Lower energy consumption

– Compliance with sustainability goals

– Minimized downtime

– Safer and healthier work environments

– Decreased use of harmful chemicals

Bad water quality can lead to health issues for consumers. These issues include dry skin and dull hair. It is important to check pH levels to keep treated water safe.

It’s important to note that pH instability can be expensive. Fixes often need extra chemicals, which raise costs and may cause system downtime. In most regular wastewater facilities, operators see a pH range of 6.5 to 8.5 as neutral and safe.

Keeping the water in the right pH range and checking it often can help save money. Choosing the right pH sensors is important for good water quality. Adding a third electrode to a differential sensor makes it work better. This change helps in many industrial uses, such as wet scrubbers.

Advantages of Our pH Sensors

Coda offers complete water quality monitoring solutions for different clients. We focus on water quality sensors and IoT technology. This helps us make our monitoring systems smarter and more automated.

We provide pH standard solutions and pH buffer solutions. These tools help users use pH sensors safely. They make pH measurements easy and accurate.

As a top maker of environmental monitoring tools, we offer many types of water quality sensors. These include pH sensors, conductivity sensors, turbidity sensors, chlorine sensors, dissolved oxygen sensors, COD sensors, ORP sensors, chlorophyll sensors, and various ion sensors. If you have any questions about pH monitoring, we encourage you to get in touch with us.