inclinometer sensor and Tilt Sensor: Functionality, Types, and Applications

The measurement inclinometer of tilt angles plays a crucial role in geometric metrology, enabling precise analysis across a wide range of applications. These angles can be sorted based on where they are in space.

There are horizontal angles, also called azimuth angles, which are in horizontal directions. Vertical angles, or inclination angles, are in vertical directions. Lastly, spatial angles mix both horizontal and vertical measurements.

An inclinometer is a type of sensor. It measures how much an object tilts or dips compared to gravity. Below, we will look at how inclinometers work, the types available, and what they are used for.

What Is an Inclinometer?

Inclinometers, also known as tilt sensors, are tools that measure angles or changes in fixed structures. They are useful tools in many fields. These tasks include building bridges, laying down railways, and working on civil engineering projects. They also check if structures are safe.

The way you install inclinometers depends on where you will use them. You can mount them vertically to watch for changes in support walls, embankments, or cutting slopes.

They can also be set up horizontally. This helps manage foundation trenches and level farmlands. It keeps them flat.

How Inclinometers Work

Tilt sensors work by sensing acceleration. A system cannot measure speed directly, but it can measure how fast something speeds up. You can find linear velocity and displacement by adding the starting speed to the measured acceleration.

Inclinometers are sensors that measure how much something tilts or leans. They work based on the principle of inertia. When it is still, an inclinometer only measures the pull of gravity.

This is due to the absence of lateral or vertical movements. The angle formed between the sensor’s vertical axis and its sensitive axis indicates the degree of tilt.

Types Based on How They Are Built and Work:

1. Single-Axis Tilt Sensor

Single-axis tilt sensors measure changes in angle along one axis. Their operation uses Newton’s second law. They apply inertial principles to measure acceleration.

Single-Axis Inclinometer

It uses inertia to measure acceleration when there are changes in one direction.

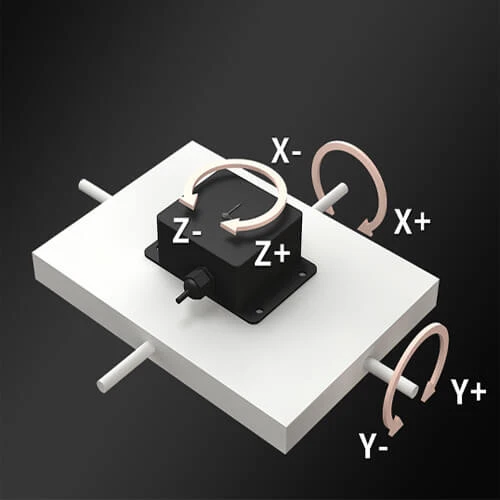

2. Dual-Axis Tilt Sensor

Dual-axis tilt sensors detect variations in angle across both the X-axis and Y-axis. They use motion calculations and laws of inertia that are built-in.

These sensors have two parts that sense. They are placed at a 90-degree angle to each other. Their digital output depend on how they tilt compared to the vertical axis.

Dual-Axis Inclinometer

Tracks changes in angles on two axes for better measurement accuracy.

Key Differences Between Single-Axis and Dual-Axis Tilt Sensors:

There are different ways to install single-axis and dual-axis sensors. These methods give different measured angles. Dual-axis sensors can measure both roll and pitch angles.

Single-axis sensors can measure just one angle. They can measure either roll or pitch. This relies on their configuration during the installation process. For instance:

– **Single-Axis Sensors**:

You can only measure flip angles when the device is installed horizontally. You cannot record pitch angles at the same time.

– **Dual-Axis Sensors**:

It can measure roll and pitch angles at the same time. This is possible because it has two axes.

Dual-axis inclination sensors define their active area as a point or a line. In contrast, single-axis sensors usually limit it to a line. For example:

A **single-axis tilt sensor** is enough to monitor the tilt of a vertical wall. The line where the wall meets the foundation is the active part.

To measure the slow tipping of a vertical rod, you need a dual-axis tilt sensor. This sensor is important for accuracy.

**Types of Tilt Sensors Based on Their Working Principles**

1. **Solid Pendulum Tilt Sensor**

The solid pendulum tilt sensor uses a force-balanced servo system to work. This system usually includes a pendulum, a cycloid, and a bracket.

The pendulum is affected by gravitational force (G) and its own pulling force (T). This results in a net external force of **F = Gsinθ = mgsinθ**. Here, **θ** is the angle between the cycloid surface and the vertical direction.

When measuring in a small angle range, the link between **F** and **θ** can be seen as linear. This principle is the foundation for tilt sensors that measure strain. The system’s structure allows precise measurement, leveraging this linear dependence.

2. **Liquid Pendulum Tilt Sensor**

The liquid pendulum has a glass shell. Inside, it holds a conductive liquid. There are three platinum electrodes spaced evenly outside the shell. These electrodes are parallel and placed equally into the liquid when the housing is flat.

When you apply an alternating voltage of the same strength to two electrodes, it creates ionic currents. Here, the conductive liquid acts like two resistors: **RI** and **RIII**. If the pendulum remains horizontal, **RI = RIII**.

When the shell tilts, the conductive liquid spreads unevenly among the electrodes. This changes how deep they are immersed. The central electrode stays mostly the same. The left and right electrodes have different depths.

– On one side, reduced depth leads to fewer conductive ions, increasing resistance (**RI**).

– On the other hand, a deeper immersion in the opposing electrode lowers resistance (**RIII**). This leads to **RI > RIII**. If tilted the other way, the relationship changes to **RI < RIII**.

*Schematic Representation of Liquid Pendulum Mechanism*

3. **Gas Pendulum Tilt Sensor**

The gas pendulum tilt sensor has a sealed space filled with gas. It uses a hot wire as its main part. When the cavity tilts or moves, heat energy moves between the gas and the hot wire.

This changes the resistance of the wire. These variations in resistance are associated with the tilt angle (**θ**) or acceleration, similar to pendulum motion.

In this system, heat convection acts as the primary mode of thermal energy exchange. The gas is heated by a hot wire. This wire is the only source of heat in the cavity. The gas moves and shows small changes in resistance.

**Comparison: Solid Pendulum vs. Liquid Pendulum vs. Gas Pendulum Sensors**

Each type of sensor has its own benefits based on what the application needs.

– **Solid Pendulum Tilt Sensor:**

The features include a clear length for the pendulum and its center. It works on principles like those of acceleration sensors. Known for high measurement ranges and high precision.

– **Liquid Pendulum Tilt Sensor:**

It combines accuracy and steadiness. This makes it good for high-accuracy systems while keeping it simple to use.

– **Gas Pendulum Tilt Sensor:**

It uses gas as its sensitive mass in a sealed cavity. This design is lightweight, which helps it resist vibrations and impacts well. However, precision may be lower compared to other types, and motion control can be complex.

Applications of inclinometers:

1. Inclinometers are used in machines that level foundation trenches. They help with both foundation trench and farmland leveling. They check and manage flatness to get accurate results.

2. In paddy fields, inclinometers assist in leveling the ground. They also help with irrigation and fertilizer use in rice farming.

3. In vehicle-mounted photoelectric tracking devices, dual-axis sensors help keep the base level. This allows for the precise use of the tracking equipment on the ship.

4. Urban pipeline robots use inclinometers to work better.

5. In ship-launching processes, inclinometers play a crucial role.

6. On ships, inclinometers help keep satellite tracking antennas stable. They keep the antennas straight to do this. This motion control works in real-time. It keeps the hull’s pitch and roll separate, so the platform stays level.

7. Inclinometers help track and adjust the swinging motion of hooks on big ships. This makes operations safer.

8. These devices are used in many industries. They help measure angles in buildings and monitor unsafe structures.

They also help preserve old buildings. And they assess bridge angles and monitor tunnels. They check dam safety and control drilling angles.

Installation guidelines for inclinometers:

The installation of inclinometer sensors requires attention to detail. The majority of inclination sensors include a zero adjustment feature. This makes it easy to set the zero at a specific angle. Before you install, find the exact spot and plane you want to measure in relation to the surface you want.

When you attach the inclinometer to the plane, press the button to adjust it to zero. This will calibrate the sensor before you take measurements. This step lowers mistakes and helps us understand angles better when we use it.