How Tank Level Sensors Function

Tank level sensors are important tools for measuring how much fluid is in tanks. They are used in many industries. These include oil and gas, making chemicals, treating water, and farming.

This overview looks at how tank level sensors work. It also looks at their uses in different industries.

Introduction to Tank Level Sensors

Understanding Their Role

Tank level sensors are electronic devices. They check and measure fluid levels in containers or tanks carefully. They use advanced technologies to give real-time data. This helps with effective management and control of operations.

How a Tank Level Sensor Works

Key Mechanisms in Action

1. **Pressure Transmitter Using Hydrostatic Pressure**

Pressure transmitters are one of the most common types of tank level sensors. These devices use hydrostatic pressure to work. This is the pressure a liquid creates at a certain height.

Inside the pressure transmitter, a sensor detects the pressure. An electronic circuit then changes this pressure into an electrical signal. Once calibrated, the signal provides clear readings of the fluid level for monitoring.

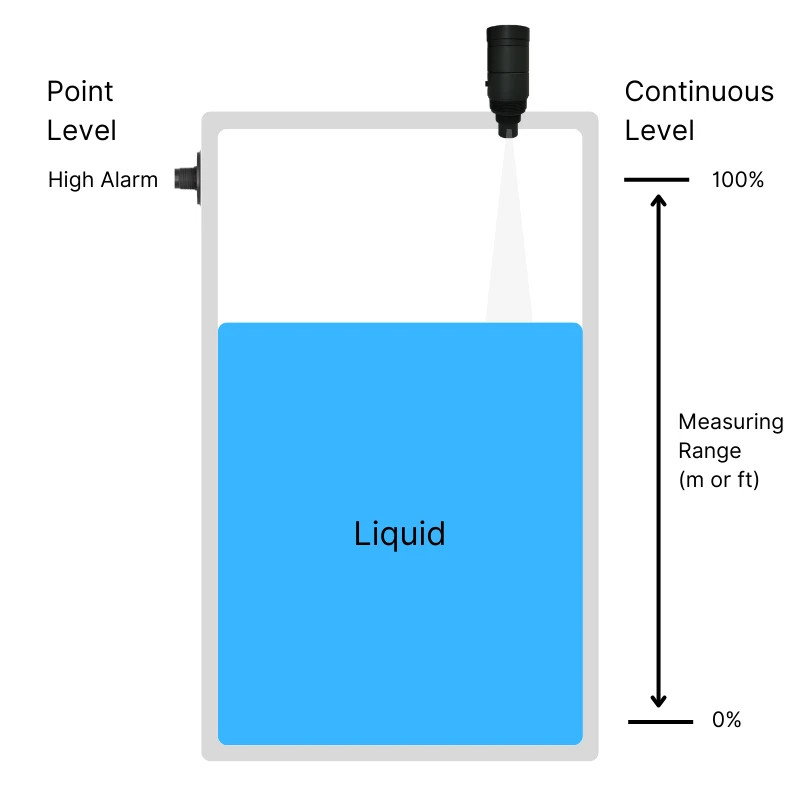

2. **Ultrasonic Level Measurement**

Ultrasonic sensors are used to measure fluid levels. They do this by sending sound waves from a transducer at the top of the tank. These waves move through the air and bounce back when they hit the surface of the liquid.

The sensor measures how long the waves take to travel. This helps find the distance from the transducer to the liquid level. The data is then turned into clear measurements for accurate monitoring.

3. **Capacitance Level Sensing**

Capacitance sensing relies on electrical capacitance to gauge fluid levels. The sensor has two electrodes. One part is in contact with the liquid, and the other part is insulated. Together, they make a capacitor.

The liquid serves as the dielectric material. As the fluid levels change, the capacitance changes too. This helps to calculate and show fluid levels accurately.

4. **Radar Level Measurement**

Radar sensors use microwave pulses to find fluid levels. They are placed above the tank. These sensors send out pulses that go to the liquid surface and bounce back.

The sensor measures how long it takes for the waves to come back. This helps it find the distance to the liquid level. It then changes this information into clear and helpful readings.

Applications of Tank Level Sensors

Supporting Diverse Industries

1. **Oil and Gas Industry**

Tank level sensors help manage storage tanks that hold petroleum products, such as crude oil. They help prevent overfilling, improve how we manage inventory, and ensure safe handling during work.

2. **Chemical Processing Plants**

In chemical plants, these sensors are essential for checking fluid levels in tanks with different chemicals or substances. Their accuracy lowers spills, controls how much is used, and maintains stable conditions during production.

3. **Water Treatment Facilities**

Tank level sensors play a key role in water treatment plants. They help track fluid levels in storage tanks. These tanks hold treated water or chemicals. Sensors allow for better process control and resource management during treatment cycles.

4. **Agriculture and Irrigation**

In farming, these sensors help check water and fertilizer levels in storage tanks. This helps farmers create plans for when to water their crops. They can then provide enough water and nutrients to crops for the best growth.

5. **Pharmaceutical and Food Industries**

Precision is very important in making medicines and food. Tank level sensors help control fluid levels when mixing, filling, or packaging. This guarantees product quality and follows the rules set by regulators.

Conclusion

Tank level sensors are important tools. They help monitor and manage fluid levels in many industries. They use technologies such as pressure transmitters, ultrasonic measurement, capacitance sensing, and radar systems.

These sensors help stop spills, make operations better, and keep safety in industrial processes. They are important for storing oil, processing chemicals, treating water, and farming. These sensors help maintain the right fluid levels and boost overall productivity.

These devices fit easily into many parts of modern life. They show how important they are in different systems.

We aim to help the communities we serve. And we aim to be a trusted resource for our customers. We aim to be a place where new sensor solutions can grow and improve.

Tank level sensors are a great choice for environmental monitoring systems. Not valuing them can lead to big problems. Take action now before the chance is lost.