How do ultraviolet sensors work & uv sensors sensing

Introduction

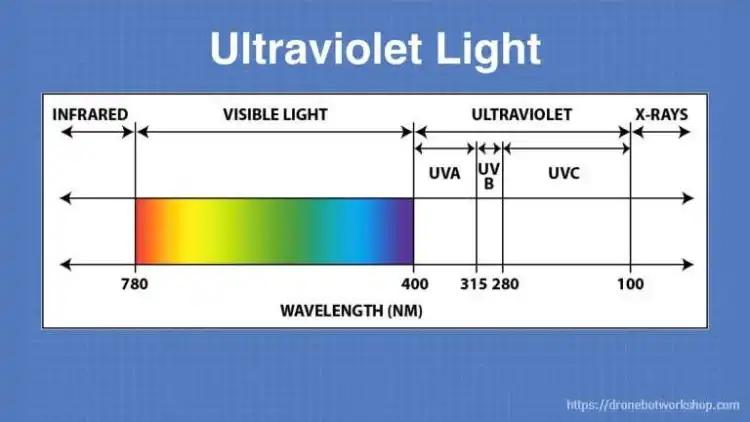

Ultraviolet (UV) radiation is a kind of electromagnetic radiation. Its wavelengths are shorter than visible light. They are longer than X-rays.

UV radiation ranges from about 10 to 400 nanometers (nm). It is a natural part of our environment. But too much exposure can harm our health.

It can cause skin damage, cataracts, and raise the risk of skin cancer. UV radiation affects many industrial, scientific, and environmental processes. Ultraviolet sensors are useful tools for finding and measuring UV radiation.

They protect human health. And they also watch for changes in the environment. They ensure that industrial products are of good quality. Knowing how these sensors work helps us see why they matter and how we can use them.

The Basics of Ultraviolet Radiation

UV radiation has three main types. They are based on wavelength.

There are three types of UV light: UVA, UVB, and UVC. UVA ranges from 315 to 400 nm. UVB spectral range from 280 to 315 nm. UVC ranges from 100 to 280 nm.

UVA has the least energy of the three types. It can go deep into the skin. This can lead to skin aging and may cause long-term damage.

UVB has more energy and mainly causes sunburns. It is also a key factor in skin cancer development. UVC has the most energy, but the Earth’s ozone layer mostly absorbs it.

This stops it from reaching the surface in normal conditions. Many applications use artificial UVC sources, like germicidal lamps, for disinfection.

Working Principles of Ultraviolet Sensors

Photovoltaic Principle

One common way ultraviolet light sensors work is through the photovoltaic principle. These sensors often use materials like silicon or gallium nitride. This material has special electrical properties when UV light hits it.

When UV photons hit the semiconductor material, they give their energy to the electrons inside the material. If the energy of the photons is high enough, it can excite electrons. This moves electrons from the valence band to the conduction band. This creates pairs of electrons and holes.

In a photovoltaic UV sensor, an electric field inside the semiconductor separates the electron-hole pairs that are created. This separation of charges creates a voltage or an electric current. This depends on how the designer designs the sensor.

The strength of the voltage or current produced depends on the intensity of the UV radiation hitting it. In a simple silicon-based uv detectors, more UV photons hitting the silicon surface create more electron-hole pairs. This results in a higher analog output current or voltage.

Photoconductive Principle

Another key principle for UV sensors is the photoconductive effect. Photoconductive UV meters use semiconductor materials but work in a different way.

In a photoconductive sensor, the semiconductor material has high resistance when it is dark. When UV radiation strikes the material, it absorbs the photons. This excites electrons from the valence band to the conduction band, like in the photovoltaic process.

In a photoconductive sensor, new free electrons and holes raise the conductivity of the semiconductor. As conductivity goes up, the material’s resistance goes down.

Measuring the change in resistance helps us find out how strong the UV radiation is. A cadmium sulfide (CdS) UV sensor changes its resistance when it sees UV light.

When it is exposed to UV light, the sensor’s resistance drops a lot. You can turn this change in resistance into a measurable electrical signal with the right circuit.

Gas – Discharge Principle

Some ultraviolet sensors work using the gas-discharge principle. These sensors have a chamber filled with gas, often argon or xenon.

When UV radiation enters the chamber, it breaks apart the gas molecules. Ionization happens when UV photons have enough energy to remove electrons from gas atoms. This creates positively charged ions and free electrons.

The ionized gas can conduct electricity. An electric field can make a current flow through the chamber. The strength of the UV radiation affects how strong this current is.

When more UV index radiation enters the chamber, more gas molecules ionize. This leads to a higher current.

People often use gas-discharge UV meters when they need a simple and effective way to detect things. However, they may not be as sensitive or precise as semiconductor-based sensors.

Types of Ultraviolet Sensors

Silicon – Based UV Sensors

Silicon-based UV meters are popular. They are low-cost, easy to make, and work well in some UV wavelengths. Designers can make these sensors as photovoltaic or photoconductive. Silicon has a bandgap that allows it to absorb UV light.

This is especially true for shorter wavelengths, like UVC and lower UVB. People often use these sensors to check UV water disinfection. They can measure how much UV light there is and how strong it is. This light can kill bacteria and viruses in water treatment systems.

Gallium Nitride (GaN) – Based UV Sensors

GaN-based UV probes have become very popular in recent years. GaN has a wider bandgap than silicon. This allows it to detect higher-energy UV radiation, such as UVB and UVA.

These sensors are very sensitive and respond quickly. They also remain stable in many different conditions.

Researchers use GaN-based uv sensing more often in solar uv radiation monitoring. Accurate measurement of UV components in sunlight is important. This helps us see how UV affects the environment and our health.

Photomultiplier Tube (PMT) – Based UV Sensors

Photomultiplier tubes are very sensitive devices. They can be used to detect UV light. They work by first converting incident UV photons into electrons through a photocathode material.

The tube speeds up and increases the number of electrons using several dynodes. Each dynode releases many secondary electrons when an electron strikes it.

This creates a strong boost to the original electron signal. PMT – based UV probes are extremely sensitive and can detect very low levels of UV radiation.

Researchers often use them in scientific research. For example, researchers use them in spectroscopy tests. These tests require accurate measurements of weak UV signals.

Applications of Ultraviolet Sensors

Environmental Monitoring

UV probes are important for checking the environment. They measure how strong UV radiation is in the air. This helps us see how UV affects the environment and our health. Scientists can study how ozone depletion changes UV exposure by tracking UV levels.

A thinner ozone layer allows more UVB radiation to reach the Earth’s surface. This information is key for finding ways to protect the environment and our health. This includes using sun protection guidelines and checking how well ozone-layer protection works.

Health and Safety

In the field of health and safety, UV probes are used in various ways. Manufacturers use UV probes to check how well sunscreens and other sun protection products block UV rays. Manufacturers can measure how much UV radiation goes through a sunscreen sample. This helps them make sure their products meet safety standards.

People also use UV probes for workplace safety. They help in industries where workers might face artificial UV sources, like in UV curing processes. These sensors can warn workers when UV levels go above safe limits. This helps stop health issues caused by UV exposure.

Industrial Processes

In factories, UV probes are used in many different processes. In the printing industry, companies use UV sensors. These sensors help them check how UV-curable inks are curing.

By curing the inks well under UV light, manufacturers can improve printed products. This makes them better and more durable.

In the electronics industry, UV probes help in processes like curing adhesives and coatings. Precise control of UV exposure is important for product quality and reliability.

Challenges and Future Developments

Ultraviolet sensors have many uses, but they also face some challenges. One of the main challenges is achieving high sensitivity and selectivity across a broad range of UV wavelengths. Different applications need accurate detection of specific UV ranges.

Making sensors that work well in all these situations is a tough job. Environmental factors like temperature, humidity, and other pollutants can affect how UV probes function. This can cause measurement errors.

Looking ahead, research and development will work to solve these challenges. Researchers study new materials and methods to make UV probes more sensitive, selective, and stable.

For example, creating nanomaterials and nanostructured surfaces can enhance how UV radiation affects sensor materials. This can help with better detection. Researchers are working on adding advanced signal-processing methods and wireless communication to UV probes.

This will allow for real-time monitoring and remote data collection. These improvements will increase the future uses of these sensors.

Conclusion

Ultraviolet sensors are important devices. They work in different ways and have many uses. These sensors use photovoltaic, photoconductive, or gas-discharge principles. They give important information about UV radiation levels.

UV sensors are essential tools. They help with environmental monitoring, health and safety, and improving industrial processes.

As technology evolves, we face new challenges and explore new possibilities. Ultraviolet sensors will play a bigger role in our lives. They will help us understand and manage the effects of UV rays better.